Composites for Nuclear Plants and Wind Turbines

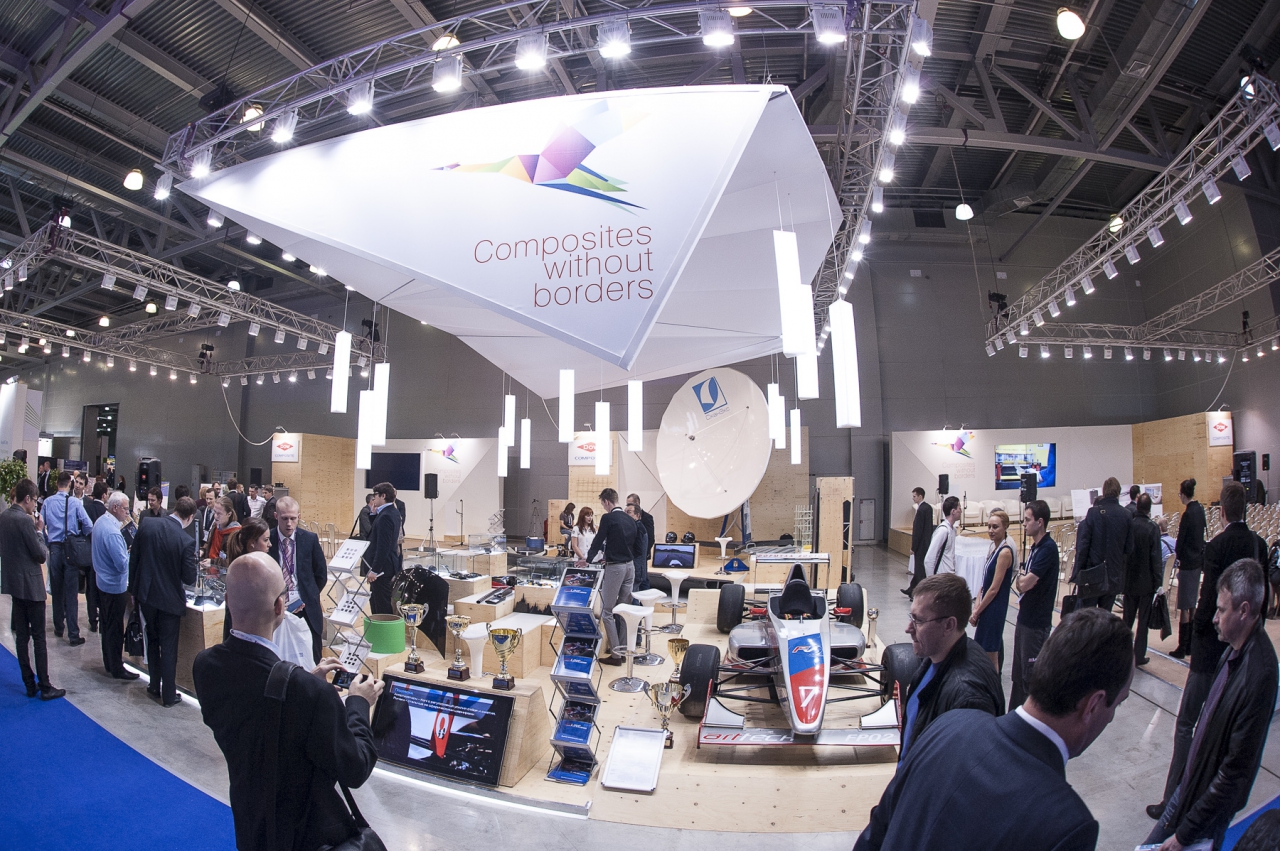

back to contentsLast week Moscow hosted the 5th Composites without Borders Forum where Russian and international businesses discussed major trends in the global composite industry. The forum was organized by UMATEX Group (Rosatom) in association with the Union of Composite Material Manufacturers under the auspices of the Russian Ministry of Industry and Trade and was attended by more than 500 people.

Addressing the plenary session entitled ‘Russian Composites – Breakthrough Solutions and Materials Today and Tomorrow’, Rosatom’s First Deputy CEO for Corporate Development and International Business Kirill Komarov spoke about the corporate strategy in developing new businesses, including composite materials. Rosatom is a long-standing manufacturer of carbon fiber in Russia. Argon, one of its oldest carbon fiber manufacturing subsidiaries, was commissioned in the 1970s. Another plant was put in operation in 2015. Alabuga-Volokno is capable of producing over 1,400 tons of carbon fiber per year. This is far more than enough to satisfy the Russian market, which has a size of just 300 tons per year. Products of the new plant meet international standards and are exported to many countries.

For wind and nuclear

According to Kirill Komarov, Rosatom plans to use composite materials in nuclear plant construction projects. Components that can be made of composite materials include road surfaces, lighting posts, pre-fabricated bridges, composite reinforcement fiber and bars for concrete structures, fencing, high-pressure vessels, and pipelines.

Composite materials will also be used in wind turbines. Rosatom plans to establish local production of composite turbine blades with carbon fiber stiffening ribs, and make nacelle housings of composite materials.

How to expand the market

Development of the composite material market is a task of UMATEX Group, one of Rosatom’s subsidiaries. It is Russia’s largest and Top 10 global producer of carbon fiber products. Alexander Tyunin, CEO of UMATEX Group, told the Forum how to scale up the carbon fiber market from 300 tons in 2017 to 3,000 tons in 2025. He mentioned four priority areas that will contribute to a tenfold market growth. Local production of wind turbine blades will alone consume 500 tons of carbon fiber per year. Production of Generation IV pressure vessels will require 700 tons of carbon fiber every year. Sports equipment might add another 400 tons to the annual consumption of carbon fiber.

According to him, the construction industry needs about 500 tons of composite materials every year. He also thinks that cooperation between domestic manufacturers of carbon fiber will give momentum to the composite industry. For this purpose, UMATEX Group is working to create a composite material cluster that will bring together production facilities in the Republic of Tatarstan, Moscow Region and Saratov Region.