New VVER-440 Fuel on Track

back to contentsThe new modification of second-generation VVER-440 nuclear fuel is developed under the export contracts between Rosatom’s TVEL Fuel Company and NPP operators in Finland and Hungary. The modernized fuel increases the volume of coolant inside the reactor core and has an improved water to uranium ratio with a positive effect on both the technical and economic performance of the power unit.

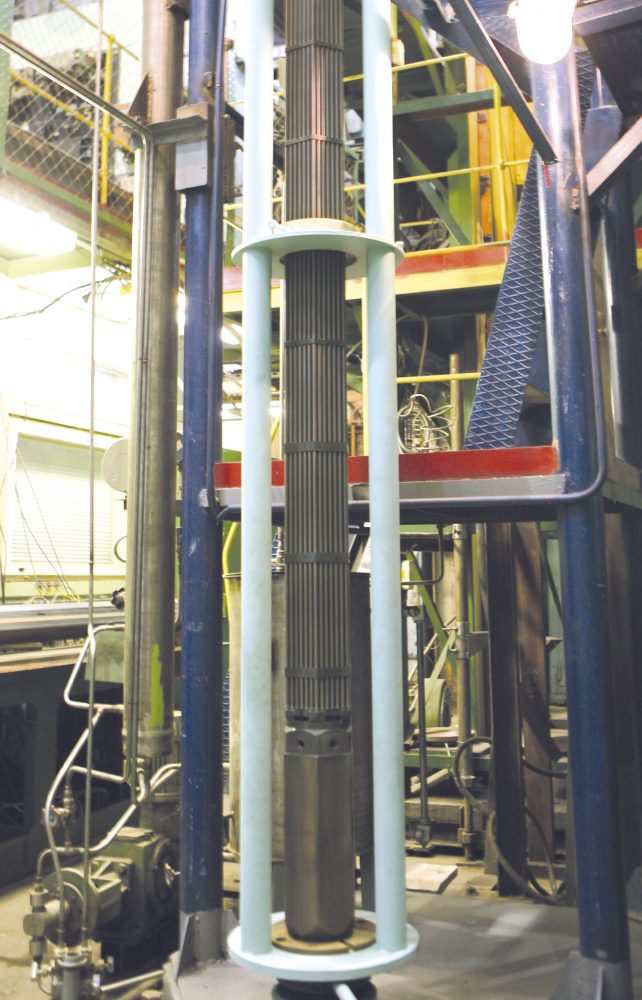

Longevity testing is a key step in the nuclear fuel development process and is of primary importance for the customers. It demonstrates how structural materials will behave inside the reactor core. Longevity tests took 1,500 hours while researchers were studying the behavior of dummy fuel assemblies in a coolant flow simulating conditions inside the reactor, such as coolant flow rate, temperature, pressure and pressure fluctuations.

After the tests were completed, the dummy assemblies were examined and assessed, with test results demonstrated to the representatives of Fortum Power and Heat (Finland), Paks NPP (Hungary) and the Hungarian regulator. It was noted that the methodology used in longevity tests (for example, fuel burnup imitation) helped verify and validate performance parameters of the modified fuel throughout the active phase of the nuclear fuel cycle.

“The new fuel for the Hungarian and Finnish nuclear power plants employs the same design, but Rosatom’s TVEL Fuel Company will be able to customize it and create an exclusive final product that will meet each customer’s fuel cycle strategy and other individual requirements. Our design solution with an increased uranium load enables us and our customers either to make the nuclear plant operation more cost efficient by reducing the number of fuel assemblies, or to lessen the level of uranium enrichment,” Alexander Ugryumov, Vice-President for R&D at TVEL, commented on the test results.