News

Northern Sea Route. The nuclear icebreaker Sibir has, for the first time ever, escorted an Arc7-class vessel using the so-called “close-coupled towing” method. “This task was professionally very demanding, as it required us to account for the design specifics of both the icebreaker and the vessel, and ensure flawless coordination between the two crews,” said Yakov Antonov, Director General of Atomflot, Rosatom’s nuclear fleet operator. Given the exceptionally late season for navigation in the eastern Arctic sector, preparations for the escort operation began well in advance. Icebreaker captain Konstantin Kelarev and his colleagues rehearsed the procedure on an ice navigation simulator. Currently, eight nuclear icebreakers are operating on the Northern Sea Route. In 2025, 23 transit voyages were completed via the NSR, with the volume of cargo transit increasing by 3.82% to reach a record 3.2 million tonnes.

Nuclear medicine. A new radiopharmaceutical drug, Rakurs 223Ra, has entered the Russian market. Its active component is the radionuclide radium-223 manufactured by Rosatom. All technologies for manufacturing this valuable isotope, developed by Russian nuclear scientists, are patented. The drug will be used to treat certain types of cancer, primarily bone metastases. According to medical assessments, patients receiving this treatment can expect sustained remission, reduced pain, and improved quality of life. The first batch of the medication has already been delivered to medical institutions across the country. Rosatom is scaling up production of a broad range of medical equipment and radiopharmaceuticals, working to build a comprehensive system for delivering advanced nuclear medicine care.

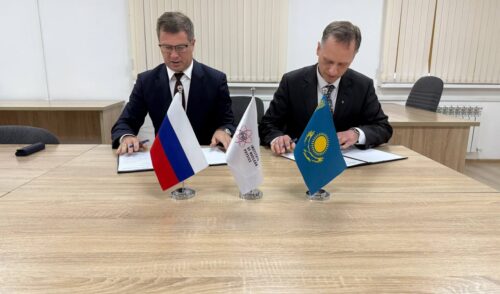

Collaboration. Rosatom and Namibia have discussed ways to advance cooperation in peaceful uses of nuclear energy. During the meeting, Nikolai Spassky, Rosatom’s Deputy Director General for International Relations, and Namibia’s Minister of International Relations and Trade, Selma Ashipala-Musavyi, discussed, among other topics, joint projects in uranium mining and preparations for signing a framework intergovernmental agreement. Both parties confirmed mutual interest in deepening collaboration and agreed to maintain regular working contacts. Throughout 2025, Rosatom signed new cooperation agreements for nuclear new build projects in Uzbekistan and Kazakhstan, and memoranda of understanding with Myanmar, Indonesia, and Ethiopia.