Long-Awaited Standard

back to contentsTechnecium is used for diagnostics of many diseases. The opening of the new department guarantees the provision of this unique pharmaceutical product to all Russian clinics. The Obninsk branch of NIFKhI is a a radiochemical center, doing research in the fields of radiochemistry, radiation solid-state physics and high-molecular compound chemistry. The Institute specializes in radiopharmaceuticals and materials, improved by ionizing radiation. The institute has been producing generators for several decades, having so far produced more than 50 000 items.

Due to new equipment and technology the institute can now issue production that meets the GMP international standard. The GMP certificate will be received by the end of the year, the Obninsk branch being the only Russian enterprise that meets its requirements.

New level

These days radionuclide diagnostics is gaining popularity in the world. The method suggests radioactive substance to be introduced into human body, allowing the doctors to diagnose the disease at an early stage.

Technecium-99m is the basic radionuclide used in radiodiagnosis. “85% of all research is conducted on the technecium- 99m basis, – says German Davydov, the head of the NIFKhI Diagnosis Department. – First of all it is used for oncological diseases diagnostics, all oncology labs are equipped with it. The first thing in oncology is examining human skeleton looking for metastatic lesions. It is also used in cardiology clinics for cardiovascular examinations.

The opening of the new department promises there won’t be any more trouble in supplying this important material to domestic clinics. The capacity of the new line is 200 generators a week, with all production of the highest quality.

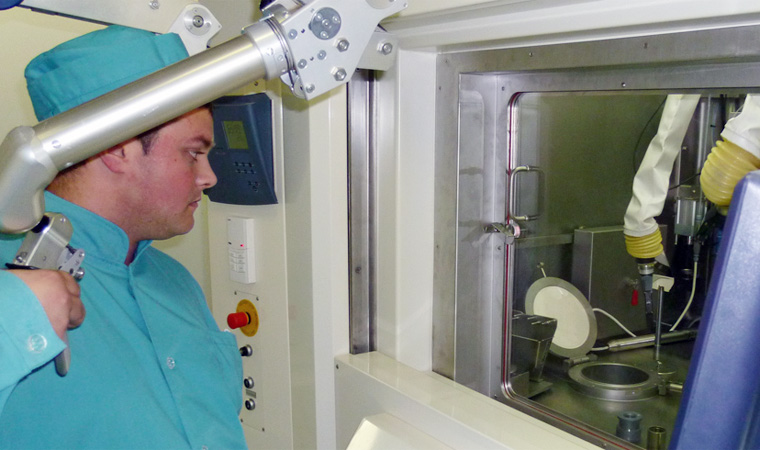

“Now we are at a new level of the technecium-99m generators production, – says Vitaly Fasdeev, the NIFKhI research officer.- The international level GMP certificate opens many new doors for us. All our production will be certified according to the world’s laboratory standards. Before they used to pick 10 samples from a 1000-item batch and checked it in order to estimate the quality of the whole batch, now the whole production will be of the same highest quality. The product will be absolutely sterile, it is an obligatory requirement for intravenous medicine. Even a small chance of a microparticle of dust is totally excluded. The new equipment allows us to achieve it easily”.

Step in the needed direction

The basis of the production line is the German ITD equipment. The project was developed by “Invar”, a pharmaceutical company. The “lungs” of the production is a two-contour air-chamber for different types of premises, while its “heart” – a sorbent staging area, temporary storage warehouse, providing good radiation protection for personnel and environment. The organization of the new department is also quite peculiar; it has a hot cell for molybdenum preparation which is joined with a hot cell in the next section. There the generators get charged and then are returned assembled, through another lock, get packed and sent to warehouse. Then the production is sent to clinics according to the schedule. “We will produce about 600 generators weekly, while today’s Russian market is about 150. Which means that the excess we can easily offer to foreign clients”, – says Oleg Kochnov, the Obninsk Branch Director.

The Obninsk generator is already registered as a new medical item in Ukraine, many clinics are ready to work with it. Having obtained the ISO 9001 certificate this April, the Institution branch started organizing small test supplying to the Philippines, India, Saudi Arabia. It’s not quite entering foreign market yet, but definitely the first step in the direction.

Nearest Future

The NIFKhI is planning to create a new department for quality control in the course of the years 2014-2015 in the Obninsk branch – with modern analytical equipment, meeting the GMP requirements. “We have to be sure that molybdenum-99m is radiochemically and biologically 100% pure”, – explains Kochnov. They also plan to locate a control room, which will automatically manage the working area support systems.

Molibdenum-99m is produced by target irradiation in the VVR-C research reactor. Soon the technological cycle will become closed: after unloading the valuable material the uranium-containing leftovers will be sent for reprocessing and further re-irradiation. This year they managed to get 60CI 99Mo from reprocessed uranium. “We already did a single ring closure. The quality of molybdenum made from reprocessed uranium is no worse. The loss is small, about 2%. I believe we will be able to do 5-6 rings like this”, – Oleg Kochnov explains. The work is financed from the branch’s own budget.

To increase molybdenum-99m production the target itself also got updated. Now it allows loading of much more fissionable material. This will fully satisfy the needs of both internal and external clients.

It is expected that in the coming two or three years, within the bounds of the nonproliferation treaty, the nuclear club will ban the use of HEU. In Russia, according to research reactors conversion program, the changing to LEU has started as early as this year. “2016 will be here soon. After this year we won’t be able even to consider possibility of selling any HEU products”, – Kochnov says.

There is another major project currently being prepared – a creation of a new unique radiochemical department for production of a radiopharmaceutical based on radioiodine and samarium.

The production of technecium generators at the Obninsk site of the NIFKhI has increased by three during the last 5 years. There is no doubt that the world demand in technecium will keep growing as well, and that Russian specialists won’t miss their good chance.