Reactor vessel to serve 120 years

back to contentsAfter a considerable research effort, the Central Research Institute for Machine Building Technology (a subsidiary of Atomenergomash, Rosatom’s nuclear engineering division) has developed a new, ultra-pure steel grade for the VVER-TOI core shell. The pilot shell was produced at OMZ SpetsStal with technological support from OMZ Izhora, which also did the testing of the new material.

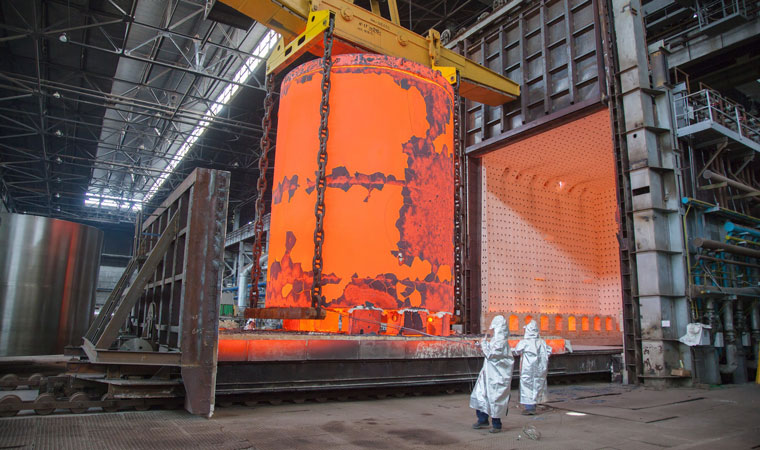

Extra strength of the reactor shell is attributed to a new nickel-alloy steel grade, explains Alexander Romashkin, the acting Deputy Director of the Metallurgy and Engineering Institute affiliated with the Central Research Institute for Machine Building Technology. This reactor shell will extend the service life of the reactor vessel up to 120 years. To manufacture the shell, a 420-ton ingot was cast for the first time after the collapse of the Soviet Union. The ingot was then forged into a record-large shell, 6m high and 4.5m in diameter. As it has no weld seams, it will be used as a part of the reactor vessel which is most intensively bombarded by neutrons.

Extension of the reactor vessel life is a key trend in the nuclear power industry. While the reactors operated in Russia have a service life of 60 years, new VVER-1200 reactors to be installed at Novovoronezh NPP and Leningrad NPP-2 will work for 100 years. Achievements of the Central Research Institute for Machine Building Technology will make reactors live more.

The VVER-TOI project to develop a large-capacity water-water reactor of a new generation was launched in 2009. A major task of the project is to develop standardized solutions which will be applicable across a variety of geographic, climatic and seismic areas, so that VVER-TOI based nuclear plants can be constructed with minor changes in any country of the world. Another task is to bring construction costs below the costs of existing solutions. And, finally, much attention is paid to the IT infrastructure, with an intention to create an intelligent decision support system for the nuclear plant.

“Development of the new steel grade proves that OMZ SpetsStal, supported by the Central Research Institute for Machine Building Technology, is now able to produce reactor shells of required dimensions and properties,” says Alexander Romashkin.

No decision has been made yet where to use the reactor shell. “It can be used in any VVER-TOI reactor vessel, including those to be installed at Akkuyu and Kudankulam nuclear power plants”, he adds.

In Russia, VVER-TOI reactors will be installed at Kursk NPP-2 (by 2020–2022) and Smolensk NPP-2 (by 2027). VVER-TOI reactors will give Rosatom a competitive advantage over its global peers.

The next step will be to set up production of reactor shells at Energomashspetsstal (a subsidiary of Atomenergomash, Rosatom’s nuclear engineering division). This is a plant where a pilot VVER-TOI shell was produced a year ago. The pilot shell was shipped to Atommash in Volgodonsk.