Success in fusion

back to contentsIt took Russia only five years to develop, test and supply 28 ‘lengths’ (separate pieces with a total length of about 18 km) of toroidal field superconductors, a key component of the fusion reactor under construction in Southern France. On 28 September, the last three lengths were loaded onto trucks at the Kurchatov Institute National Research Center to be sent to Italy. As soon as all acceptance documents are signed, the first Russian agreement for deliveries of ITER components will be officially recognized as fully performed. ASG Superconductors (Italy) will wind toroidal field coils.

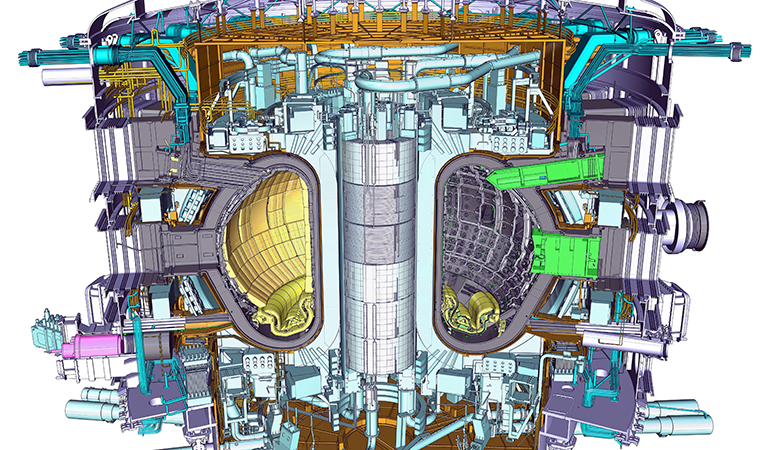

The ITER magnet system consists of 48 components, including 18 toroidal field coils, six poloidal field coils, six sections of the central solenoid and 18 correction coils. The toroidal field is needed to reduce instability of plasma while the poloidal field is used to keep the plasma pinch in place. It is impossible to generate such a powerful magnetic field without superconducting materials.

Superconductors for the ITER project are produced by six out of seven project members (Russia, China, European Union, Japan, South Korea and the USA). Weighing 2,800 tons, EUR 610m superconductors have a total length of 200 kilometers. Russia supplies about 20% of this amount. The production and testing involved Rosatom’s subsidiaries – A. Bochvar Russian Research Institute of Inorganic Materials, Kurchatov Institute, Russian Cable Industry Research institute, and Institute of High Energy Physics. Apart from toroidal field superconductors, they manufacture superconductors for the poloidal field. They will be shipped by 2017.