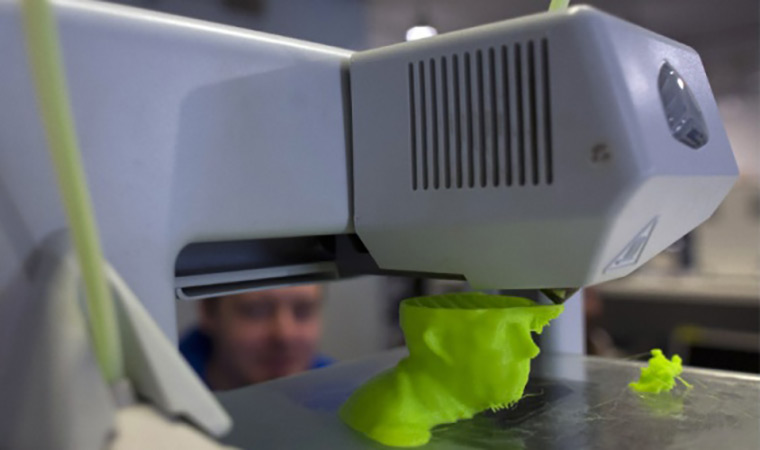

3D printer by Rosatom

back to contents3D metal printing is the most ambitious technology. Dubbed a ‘cherished dream’ of additive machine manufacturers, the technology enables the manufacturing of finished products, rather than models. According to the developers, the new 3D printer will be capable of printing titanium and stainless steel components. For Rosatom, the new product means an entry into another hi-tech market segment, and a new development phase for the national mechanical engineering industry.

The printer features a 1,000 W laser and a three-axis optical scanner. “With a printing speed of foreign counterparts – 15 to 70 cm per hour – our additive machine will be much cheaper,” promises Evgeny Tretyakov, Deputy Director for Operations at the Surface Engineering and Nanomaterials Department of the Central Research Institute for Machine Building Technology. The printer uses a selective laser melting (SLM) technology and can print metal parts using fine granulated iron, titanium, aluminum, nickel, cobalt and other powders. “They have to exhibit a certain spherical shape and free-running properties to print uniform layers. Only then the powder particles are easily shaped and have a necessary flow rate. The lesser the particles, the finer structures are fused and the higher accuracy is achieved. Luckily, such powders are produced in Russia, so we will have no problems with supplies,” says Evgeny Tretyakov.

Printing powders are manufactured by Rosatom Group companies, among them the Electrochemical Converter Plant (a subsidiary of the Ural Electrochemical Plant), Bochvar Russian Research Institute of Inorganic Materials (VNIINM), Chepetsk Mechanical Plant, R&D Institute of Rare Metal Industry, and Russian Research Institute of Chemical Technology.

Software for the printer was developed by the Central Research Institute for Machine Building Technology. Its function is to process digital 3D models designed in AutoCAD and generate a final printing work file.

The project is now in its pilot phase. “We continue research and expect to verify performance parameters by the end of the year to launch the production after that,” says Vladimir Beregovskiy, Deputy Director of the Central Research Institute for Machine Building Technology and Head of the Surface Engineering and Nanomaterials Department. “We have already received several orders.”