Small Power in Pipeline

back to contentsConstruction of hulls for floating power units, development of a detailed engineering design for a power plant with SHELF-M microreactor, and presentation of Rosatom’s small nuclear power plant in Ghana — all these speak to the fact that the Russian nuclear corporation keeps working on its small modular reactor projects and moving them through the pipeline both in Russia and in other countries.

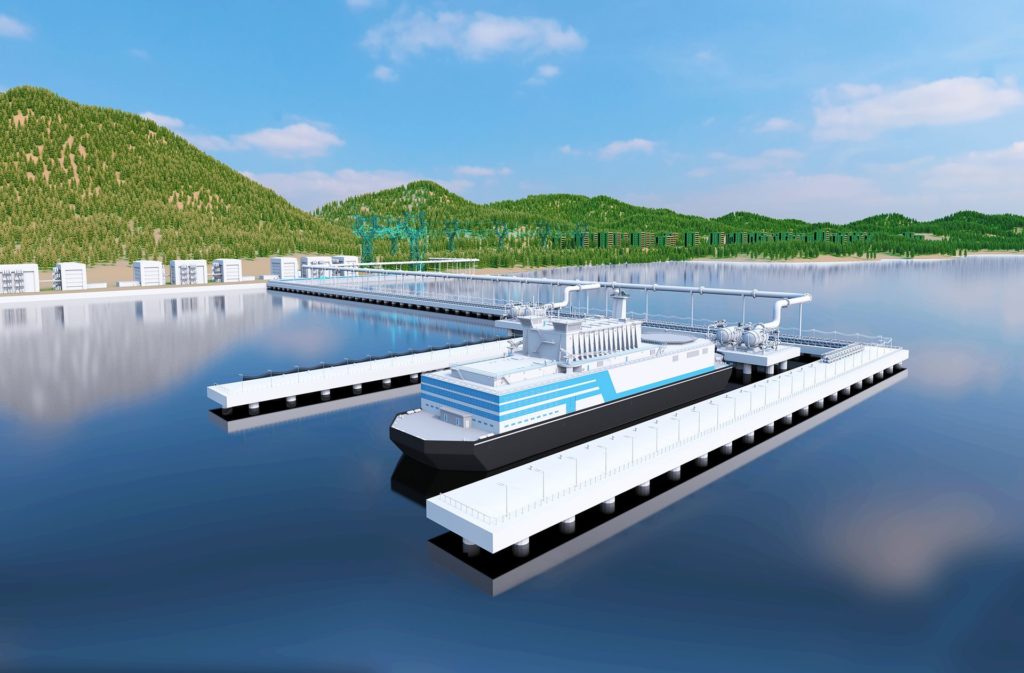

Floating power units

A keel laying ceremony was held at a shipyard in China as the workers proceeded to the construction of a hull for the first floating power unit (FPU). It is the first one for a number of reasons. To start with, it will be the world’s first FPU with a RITM‑200S nuclear reactor. Besides, it is the first out of four FPUs that will supply electric power to Baimsky GOK, a large mining and processing site at the gold and copper deposit Peschanka in the Chukotka Peninsula (Northeast Russia). The Chinese shipyard will build two hulls. The decision as to where the remaining two hulls will be produced will be made in the fourth quarter of 2022.

Weighing 9,549 tons, each hull is 140 m long and 30 m wide. With the equipment installed, its weight will increase to 19,088 tons. The first hull is expected to be delivered to Russia in 2023. The equipment to be installed in it is being manufactured at the production sites of Rosatom’s power engineering division AtomEnergoMash. The power capacity of a two-reactor FPU will be 106 MWe.

“This project will kick-start a family of FPUs varying in capacity and application, including versions for arctic and tropical climates. These are the products AtomEnergoMash can offer its customers and that certainly hold the potential for large industrial sites and exports,” says AtomEnergoMash CEO Andrei Nikipelov.

It should be noted that Baimsky GOK will be the second major site powered with electricity from floating power units. The world’s first floating nuclear power plant was brought online in December 2019 and has been supplying heat and power to the Chukotka city of Pevek since then.

SMRs in Yakutia

Dollezhal Research and Development Institute of Power Engineering (NIKIET, part of Rosatom) has won a contract to develop a detailed technical design of the reactor systems and equipment for the first small nuclear power plant with SHELF-M reactor. The design will be finalized by the end of 2024.

According to Denis Kulikov, Chief Designer of Small Modular Reactors at NIKIET, SHELF-M is an upgraded and standardized version of the SHELF water-cooled integral reactor (‘M’ stands for ‘modernized’ in Russian). Equipment for the power plant will be supplied in modules.

Each SHELF-M reactor has a power capacity of up to 10 MWe. Capacity of the power plant can be increased by adding more reactor modules. All reactor systems are placed inside a rugged housing that serves as an additional protection barrier against radiation. Another protective structure is an enclosure into which the housing is installed.

This June, Rosatom and the Russian region of Sakha (Yakutia) signed an agreement to develop and approve a roadmap for the construction of a small nuclear power plant with SHELF-M reactor. The power plant is expected to be put in operation in 2030.

The SHELF-M-based nuclear power plant is the second small-scale nuclear generation project in Yakutia. At present, Rosatom is making preparations for the construction of a nuclear power plant with RITM‑200 reactor in the same region. The plant will supply power to a gold mining facility at the Kyuchus gold deposit. It is expected that the RITM‑200‑based power plant will be brought online in 2028.

Rosatom’s small nuclear plants in Ghana

The Russian nuclear corporation presents its small-scale nuclear generation solutions in different countries. In late August, Rosatom organized a seminar on small modular reactors for the public authorities and expert community of Ghana. Rosatom told the audience about the history and application of small modular reactors, and about the SMR projects launched or in progress. Much was said about the advantages of small nuclear power plants and their specifics in terms of safety, design and cost efficiency. It was noted that the plant design combined active and passive safety systems and employed only proven solutions and technology. Besides, small nuclear power plants are less material-intensive than high-capacity plants and can be pre-assembled at the manufacturing facility rather than on the construction site, which saves time and money. Bringing small nuclear power plants online requires less effort and investment in the grid infrastructure. Small-scale generation solutions are well suited for isolated grids and remote territories. And, unlike fossil fuel power plants, nuclear-powered generation stations are almost independent of fuel price fluctuations.

Experts from Ghana shared their opinions on the prospects of nuclear generation in the country and objectives to be pursued. According to Robert B. M. Sogbadji, Deputy Director of the Nuclear and Alternative Energy Department at the Ministry of Energy, Ghana is developing a national clean energy transition plan in which nuclear power plants play a decisive role in generating baseload power. It was announced at the seminar that the parties would set up a task team to coordinate activities and exchange information.