Fuel Evolution

back to contentsRosatom’s fuel division TVEL has made much progress in developing new types of fuel, improving their safety and offering them to customers. New fuels are safer and more cost-effective, and contribute to closing the nuclear fuel cycle as they maximize the use of energy contained in natural uranium and reduce the amount of spent nuclear fuel.

Safety confirmed

The third and final 18‑month round of operation tests on REMIX fuel assemblies started at Rosatom’s Balakovo Unit 1.

Designed by Russian nuclear engineers for light-water reactors, REMIX fuel is a mixture of reprocessed uranium and plutonium, with enriched uranium added. The share of plutonium in this fuel is below 5 %. Its neutron spectrum is similar to that of ordinary uranium fuel, so the in-pile behavior of the new fuel and the amount of plutonium produced do not differ much from its conventional counterpart. These features make it possible to use REMIX fuel without extensive changes in the plant safety systems.

During the first round of tests, six REMIX fuel assemblies were loaded into the VVER‑1000 reactor at Balakovo Unit 1 in late 2021. Each of the three test rounds is equal to the typical refueling interval of 18 months. The two completed rounds were followed by a careful inspection of the fuel pellets and structural elements of the test assemblies in the hot cell. No obstacles to further operation were identified.

The third round will be completed in the first half of 2026. During the scheduled maintenance, the test assemblies will be first placed into the spent fuel pool and then sent for post-irradiation examination. “After the REMIX test program and post-irradiation studies are finished, Rosatom will have enough scientific evidence to confidently offer a new product from our Balanced Fuel Cycle concept,” said Alexander Ugryumov, Senior Vice President for Research and Development at TVEL. As the next step, TVEL plans to gradually convert one of the large reactors to REMIX fuel.

Enrichment to continue

An experimental assembly of 12 fuel rods containing erbium-doped uranium fuel was loaded into MIR.M1, a research reactor installed at the Research Institute of Atomic Reactors (RIAR, part of Rosatom’s R&D Division). Uranium in each fuel rod is enriched to about 5 %.

Irradiation of the experimental fuel assembly is the first part of the test program aimed at gradually increasing uranium enrichment to above 5 %. “So far, reactor performance has been improved by introducing new designs and modifications of fuel assemblies. Much of the innovation has consisted in increasing the physical volume of enriched uranium in the fuel rod to ultimately obtain more power from a single fuel assembly. Now, the key to further improvement of plant economics seems to lie in crossing the 5 % uranium enrichment threshold for large thermal reactors. Given the fact that the present-day VVER reactors have 163 fuel assemblies and each of them contains more than 500 kg of uranium, the effect of increasing enrichment by as little as 1 % will be very significant,” Alexander Ugryumov explained.

According to estimates by TVEL researchers, the use of erbium instead of conventional gadolinium as a neutron absorber in a combination with uranium enriched to above 5 % will make it possible to switch from 12- and 18‑month refueling intervals to 24‑month intervals. Fewer refueling outages will increase power generation and, consequently, revenue and overall economics of a nuclear power plant.

The test program provides for four one-year irradiation rounds. Results of the tests will help develop commercial technology for the production of uranium-erbium fuel for VVER reactors and make a safety case for its use at Russian-designed nuclear power plants.

Fuel for fast reactors

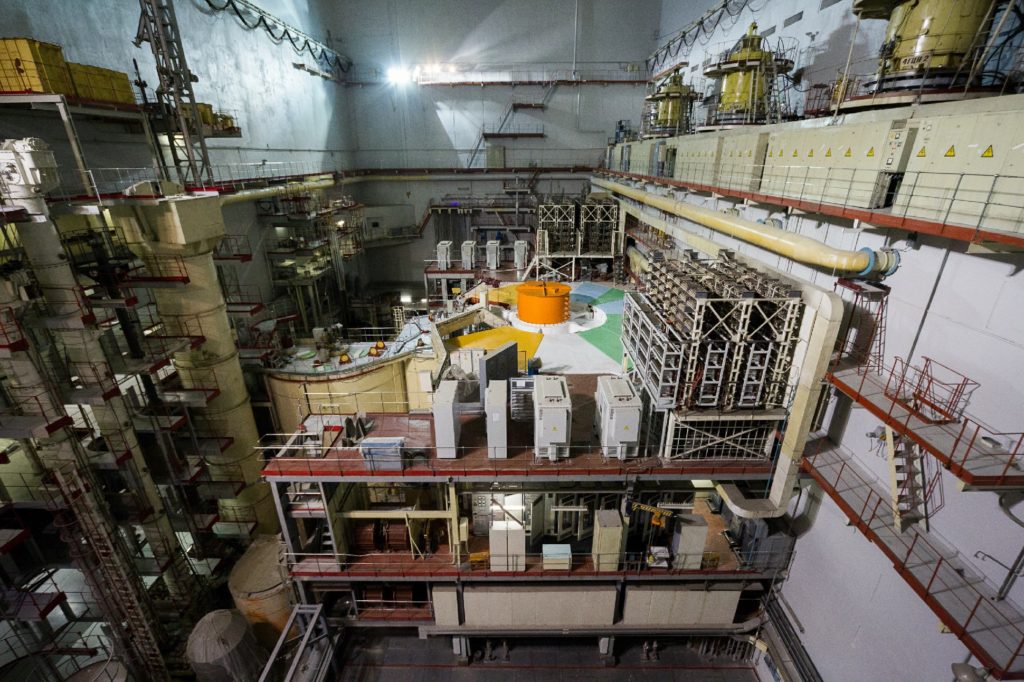

Rosatom researchers have achieved significant results in obtaining scientific evidence for the feasibility of two core modifications for Generation IV fast neutron reactors. An OS‑4 assembly with mixed uranium-plutonium nitride (MUPN) fuel was manufactured for testing in the BN‑600 fast reactor at the Beloyarsk Nuclear Power Plant. Irradiation of this assembly is expected to confirm the increased fuel burn-up estimates. The design of the assembly incorporates solutions that ensure safety of the tests.

Also manufactured were three experimental BN‑1200‑sized KTEVS-MAK assemblies containing axial-interlaid mixed oxide (MOX) fuel. Their fuel rods include fragments of fertile material (depleted uranium). Inside the reactor, these fragments will together form a horizontal layer separating the reactor core. Such a core structure is assumed to reduce radiation damage to the fuel cladding while maintaining the required fuel burn-up depth. Evidence for the feasibility of this solution has been obtained in several countries, but Russia may be the first to pilot it at the BN‑1200 fast neutron reactor.

The two types of fuel assemblies have been manufactured at TVEL’s Siberian Chemical Plant and are planned to be test-loaded into the BN‑600 reactor core in 2025.

In-pile tests and post-irradiation analysis will help researchers study the processes occurring in the new types of fuel rods and license them for the BN‑1200 reactor, the world’s largest commercial fast neutron reactor. It is assumed that both MOX and SNUP fuels can be used in the reactor. Construction of the BN‑1200 unit is scheduled to begin at the Beloyarsk NPP in 2027.

Balanced Nuclear Fuel Cycle is Rosatom’s product incorporating closed nuclear fuel cycle technologies that enable effective reprocessing and utilization of spent nuclear fuel.