VVER-1200: Flagship Reactor for Kazakhstan

back to contentsWork has begun in Kazakhstan to build a large nuclear power plant featuring VVER-1200 reactors. The project is being implemented by an international consortium led by Rosatom. Below, we take a closer look at this reactor type and how it ensures safety and efficiency of nuclear generating stations.

August 8 saw the start of engineering surveys near the town of Ulken, Almaty Region, on the shore of Lake Balkhash to select the optimal site for the nuclear power plant and prepare design documents. Rosatom’s Engineering Division started drilling the first exploratory borehole and collecting soil samples. These surveys will help assess seismic stability, hydrogeological conditions, and other site-specific parameters that are crucial for safety and reliability of the future station. At least 50 boreholes, ranging 30 to 120 meters deep, will be drilled during this phase. The collected data will inform the final decision on the plant’s exact location.

“The start of engineering surveys in Ulken marks the first step toward Kazakhstan’s first large nuclear power plant in modern history. At this stage, we focus our efforts on thoroughly studying the site to be fully confident in its suitability for the future nuclear station. Rosatom is ready to leverage its full expertise to deliver this project of strategic importance for Kazakhstan’s development,” said Alexey Likhachev, Director General of Russia’s State Atomic Energy Corporation Rosatom.

VVER-1200: leading the pack

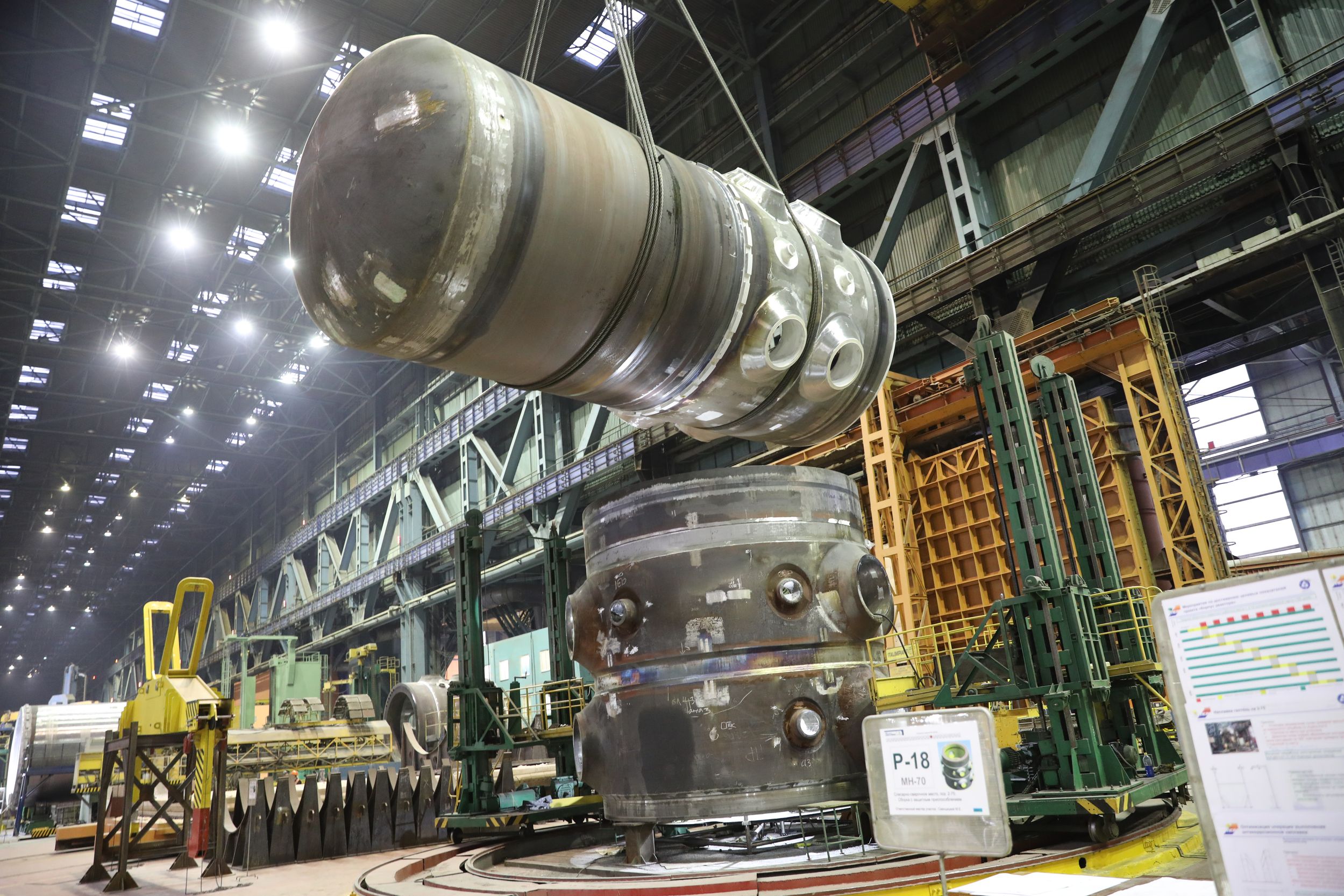

The nuclear power plant in Kazakhstan will feature VVER-1200 reactors. These are pressurized water reactors (PWRs), the design that was developed in the early days of civil nuclear technology and now dominates global nuclear power. According to the IAEA, out of 416 operating reactors worldwide, 306 are PWRs.

Among this large international family, Russian VVERs hold a key position. They form the backbone of Russia’s nuclear energy sector, with a long history of safe operation and continuous advancements in efficiency and safety.

The VVER-1200 is Rosatom’s flagship Generation III+ reactor — the most advanced, technologically sophisticated, and safest Russian design to date. It incorporates decades of experience in engineering and operating reactors of the same type. Its design life is 60 years, extendable by another 20. Other key features of the VVER-1200 include load-following capability, a high (90%) capacity factor, and the ability to operate for 18 months without refueling.

The VVER-1200 reactor unit has two circuits. The primary circuit—sealed and pressurized—contains the reactor core, where nuclear fission releases a massive amount of energy and heats the coolant, a chemically purified boron-treated water that circulates through the reactor under high pressure (16.2 MPa) and temperature (up to 328.8°C). The coolant circulates in the primary circuit via four powerful circulation pumps.

The heated water from the reactor flows into steam generators, where it transfers its heat to water in the secondary circuit. This causes the secondary water to boil and produce steam.

The two-circuit design ensures complete isolation between the circuits, meaning the water inside the reactor never physically contacts the water in the steam generators. Heat transfer occurs only through the heat exchange surface. This prevents any radioactive water from escaping beyond the primary circuit.

The generated steam is then carried through large steam lines to the turbine, where its energy spins the turbine shaft. The rotating shaft drives the electric generator, which produces electricity. The electricity generated is sent to step-up transformers and then, via gas-insulated transmission lines, to the switchyard and onward into the power grid.

Safety first

The VVER-1200 reactor unit is designed to withstand extreme, low-probability events, such as magnitude 9 earthquakes, tornadoes and hurricanes with wind speeds up to 60 m/s, tsunamis, and waves up to 10 meters high.

The design incorporates independent — active and passive — safety systems. Active safety systems are intended to quickly respond to possible accidents and emergencies. Passive safety systems function without operator intervention and even without power. It is impossible to cover all safety systems in a short article, so we will highlight just a few.

One of the most important passive safety devices — a Russian nuclear innovation — is the so-called ‘core melt trap’. It is a 144-tonne steel vessel that, in the event of an accident, reliably contains fragments of molten reactor core and prevents them from escaping beyond the reactor building’s containment structure.

Another passive safety component is the emergency core cooling system, designed to cool the reactor core using a volume of water many times greater than the reactor’s own volume. Like the reactor control and protection system, it continues operating for 72 hours even after a complete power outage.

One more innovation, the passive heat removal system (PHRS), ensures the removal of residual heat from the reactor core through the secondary circuit.

VVERs conquer the world

Rosatom is building VVER-1200 units around the world. The two largest nuclear construction projects by Rosatom are the Akkuyu Nuclear Power Plant in Turkey and El Dabaa Nuclear Power Plant in Egypt. At both sites, four VVER-1200 units are being built simultaneously. The Paks II Nuclear Power Plant in Hungary, with two VVER-1200 reactors, is the first such project in the European Union. The Rooppur NPP in Bangladesh also consists of two VVER-1200 units, both of which are under active construction. Rosatom is also involved in building two nuclear plants in China: Units 3 and 4 at Xudabao NPP and Units 7 and 8 at Tianwan NPP, all featuring VVER-1200 reactors.

“VVER-1200 reactors are already operational in Russia and abroad, four units in Russia and two in Belarus. This technology has also been selected by our partners in Hungary, Egypt, Turkey, Bangladesh, and China. There is still much work ahead, and we count on support and assistance from the leadership of both Russia and Kazakhstan,” said Rosatom Director General Alexey Likhachev.

Photo by: Rosatom, Atomenergomash