Construction at full tilt

back to contentsNovovoronezh

Novovoronezh NPP Unit 6 plans to load nuclear fuel into the reactor by the year end. The unit is undergoing the hot and cold tests, one of the last test runs for the reactor and the most important commissioning phase that includes equipment checks in design basis conditions and a set of pre-start tests. Also tested is the reactor safety control system.

The entire hot testing phase includes over 100 tests. Experts from OKB Gidropress and Kurchatov Institute (reactor designers) will measure vibration inside the reactor vessel and assess thermohydraulic properties of the equipment.

The next testing step will be pressure tests of the reactor containment. This will be followed by the equipment inspection after the design basis operation. The first fuel assembly will be loaded into the reactor core as soon as the national regulator Rostekhnadzor issues a reactor operation permit.

Volgodonsk

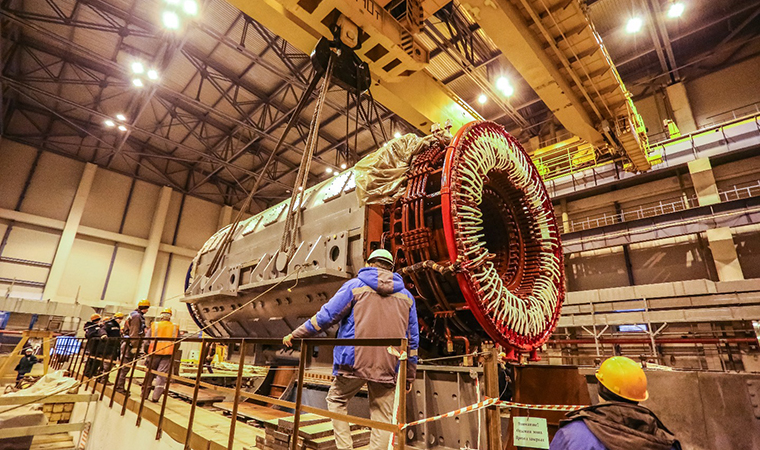

The reactor vessel will be installed in the permanent position at Rostov NPP Unit 4 by the year end. “An area inside the reactor building is being cleaned and prepared for the reactor vessel installation. After it is installed, we will move on to the assembly of other heavy equipment,” said Alexei Fedotov, Deputy Director for Capital Construction at Rostov NPP, talking about the construction progress.

In late November, two hydraulic accumulator tanks of the emergency core cooling system (ECCS) were installed in the reactor building. When pressure in the primary loop decreases below a pre-set level, water is instantly injected into the reactor and cools the core. Injected water contains much boron that absorbs neutrons and stops the chain reaction. Unit 4 is scheduled for the startup in 2017.

Sosnovy Bor

Leningrad NPP

Leningrad NPP-2 Unit 1 pushes ahead with assembling process pipes for subsequent non-pressure testing. To meet the schedule, the plans are to increase the headcount on Unit 1 site up to 4,500 people by the year end.

“To do non-pressure tests of the piping, we need to prepare the premises for cable laying and equipment installation, assemble a water treatment plant and begin producing demineralized water in large amounts, and complete installation of fire extinguishing systems in the buildings involved in the tests,” explains Yuri Galanchuk, First Deputy Director in charge of new reactor construction at the Leningrad NPP.