Facing Start-Up

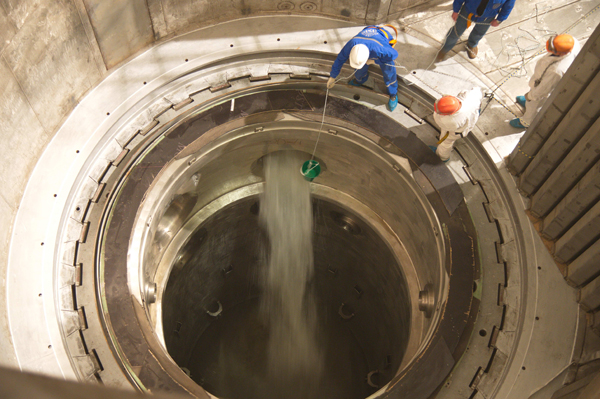

back to contentsDuring the test demineralized water is being pumped into the unit’s reactor vessel, thus verifying that the joints between the 320-tonnes vessel and attached pipelines are watertight and provide an opportunity to test the cooling system.

The test started from the pressure compensator. “The next stage will be testing the water tightness of the piping systems of four accumulators for the emergency cooling system, then safety system pipes and so on. All this brings us to the launch of the third unit,” – said Alexei Zhukov, Chief Engineer at the Rostov plant.

Finishing touches

In order to conduct the test the mounters had to make more than 20 000 joint points; electricians laid more than 3 500 km of cables. “The reactor vessel installment, the main circulation line welding and today’s water tightness tests are made within the established time limit. We are sure that further reactor assembly (after water operations) will be completed with an appropriate quality and within required period of time”, said Mikhail Pinchuk, Chief Engineer of Sezam company (does the work upon the contract with Rosatom).

The fuel for the new unit is also ready. The first 48 fuel assembly imitators were delivered on site (in total the reactor will have 163). During hot operation testing, planned for August 2014, fuel assembly imitators will be loaded inside the reactor, creating conditions equal to those of real reactor’s operation. This will help to estimate characteristics of the equipment operation: heat generation, heat loss, coolant flow etc., proving reactor’s safety and its meeting the project requirements.

Shortly the specialists will start commissioning of the refueling machine, with the help of which (after successful water tightness test in the open reactor) the specialists of commissioning will start final assembly of the reactor system in the second quarter of the year. All reactor’s in-vessel devices with a total weight of 150 tons are already at the site: an in-vessel pit, a baffle and a protective tube unit. After that the loading of fuel assemblies’ imitators for further testing will be conducted with the help of fuel-handling machine.

New stage

Another unit, which start-up is planned for the current year – unit 1 of the Novovoronezh NPP-2, where the new stage of installation and construction works has begun: post-mounting cleaning-up and systems’ equipment that are used in the work of unit 1 reactor system. Thus the systems are getting prepared for water tightness tests for the “open reactor”.

Before the beginning of post-mounting cleaning-up special desalinated water was supplied to auxiliary reactor building and then – to the reactor building, where it went to the pressure compensator through the blowing-down infeed pipelines. After the compensator the water went to the open vessel of the reactor. The post-mounting pipelines cleaning-up is planned to be fully completed in the second quarter of the current year. According to Marat Mustafin, Atomenergoproyekt General Director (contractor’s company) the beginning of cleaning-up means “an important stage of pre-start-up commissioning works. This operation’s successful completion confirms systems’ readiness and allows us to start control assembly of the reactor”.

Along with that automatic welding of one of the main pipelines of the unit 1 turbine island – feedwater pipeline – was started by Energospetsmontazh (part of Atomenergoproyekt, Rosatom’s engineering company). During the technological operation the specialists will mount 300 tons of steel pipeline in total and weld about 115 joints; 50% of them automatic welding. Applying this technique is expected to increase productivity of work by 2,5, keeping high quality stability and, as a result, to reduce materially the terms of pipeline mounting.

A lot to do

One of the most anticipated events of the year is energy start-up of the Beloyarsk NPP’s unit 4 with its BN-800 fast reactor. Together with the New Year celebration the station started the first stage of physical start-up program works. Today there are 16 fuel assembles loaded into the unit; while during the physical start up there will be 548 of those of different types. This stage will take about 3 months.

In March NIIAR (Research Institute of Atomic Reactors, Russia’s major research and experimental complex for civil atomic energy in the system of Rosatom) sent the first batch of MOX fuel assemblies for start-up loading of the BN-800 hybrid zone. 56 fuel assembles sent to the Beloyarsk plant contain tableted fuel, supplied to NIIAR by the Mayak industrial association. By the end of March the total amount of assemblies sent to the unit from Dimitrovgrad will be 106 items. The fuel for the rest 40 assemblies is made with the help of unique technologies developed by the Institute.

Another enterprise taking part in creating MOX-fuel for fast reactors is Tochmash, Rosatom’s plant in Vladimir. Last week the plant presented nuclear fuel element cold leakage monitoring installment, which will be part of the plant’s equipment in producing MOX-fuel at the Mining and Chemical Combine. As explained Igor Pozdeev, head of Tochmash project, the technological chain of fuel elements’ production suggests “the tightness is tested with the help of a specially designed installment, modern pumps, leakage detector, software and special methods”. Besides cold control, another Tochmash’s responsibility is processing equipment of hot leakage monitoring chamber, where several nuclear fuel elements are being tested at the same time. The cold control pre-testing is completed for today. After the commission acceptance the equipment will be shipped to FSUE CDBMB (Central Design Bureau of Machine Building) for mounting and on-line testing piloting. Installment of the equipment at the GKhK is planned for April or May, while mounting, commissioning and acceptance tests should be completed by the end of the year.

Also there was prestart peer review of unit 4 at the station, conducted during 4 weeks by the WANO partners. International experts from France, Russia, Ukraine, China, Bulgaria and the USA did monitoring of unit 4 objects, examined equipment, interviewed personnel and heads of departments, analyzed the systems’ readiness, were present at the emergency response drilling, visited protected command post for emergency actions.

“People who work there have lots of things to do, that’s what they are doing at the moment. We were here to help them to concentrate on main directions. At this point our work was success”, – said Jean-Marie Baggio, head of peer review team and Pre-Startup Kong Office of WANO.

WANO peer reviews are voluntary. International experts have recently started to be invited to nuclear power units which are about to be put to operation, during prelaunch period, which helps introduce best international practices to production spheres as early as during pre-startup period.