Circle of Fuel

back to contentsRosatom accumulates resources to close the nuclear fuel cycle. By defluorinating depleted uranium hexafluoride, the Russian nuclear corporation obtains uranium oxide to be used in the closed nuclear fuel cycle. The fuel cycle closing will make nuclear generation almost waste-free. Thanks to repeated recycling of one and the same amount of uranium, nuclear will become a renewable source of energy.

Working in pair

“The major issue facing the global nuclear sector now is closing the fuel cycle and thus solving the back-end challenge. If we succeed, it would turn nuclear in a type of renewable energy as basically there will be virtually no waste. Or at least no more waste than left after the end life of solar panels. It is what the next, 4th generation of reactors is expected to deliver — they would be able to burn used uranium extracted from spent fuel,” Andrei Rozhdestvin, head of Rosatom Western Europe, explains.

One of Rosatom’s strategic goals is to close the nuclear fuel cycle with a two-component approach that provides for thermal neutron and fast neutron reactors working in a combination. Thermal neutron reactors run on a fuel containing a little less than 5 % of uranium‑235. It is enriched because natural uranium contains only 0.7 % of uranium‑235. The rest is uranium‑238. Fast neutron reactors can run on MOX fuel, a mixture of depleted uranium (see below) and radioactive elements obtained from conventional nuclear fuel irradiated in power reactors.

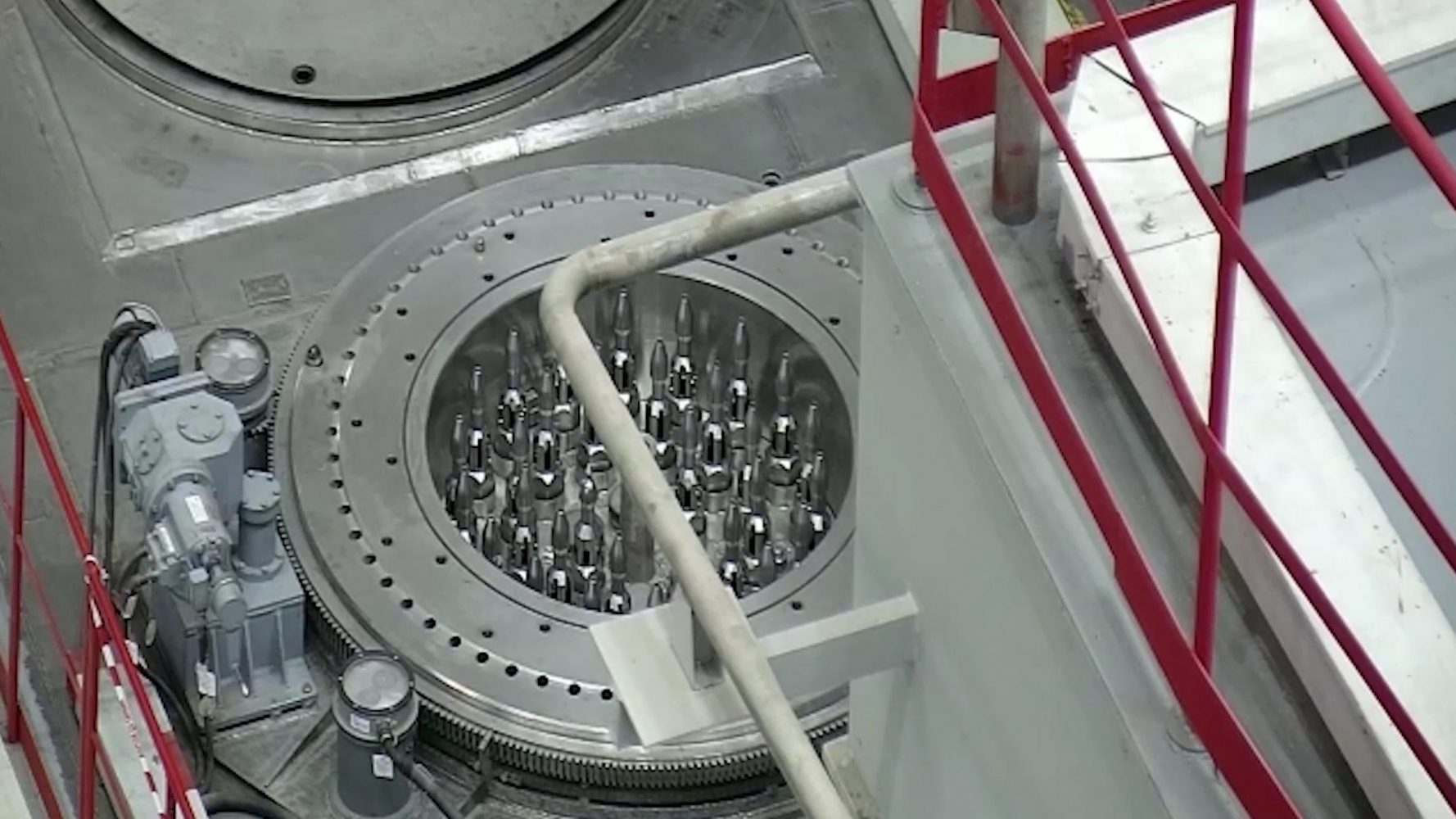

Rosatom has long been working to bring the two-component approach to energy generation to life. In January 2020, the first 18 assemblies with MOX fuel were loaded into the BN‑800 reactor. With another 160 fuel assemblies loaded into the reactor this January, MOX fuel makes a third of its total load. In 2022, conventional nuclear fuel in the BN‑800 reactor will be fully replaced with MOX fuel.

According to experts, recycling spent nuclear fuel and using a uranium-plutonium mixture in new assemblies will increase the total amount of energy extracted from natural uranium by about 100 times.

Valuable DUHF

DUHF stands for depleted uranium hexafluoride. It consists almost entirely of uranium‑238 left over after the separation of uranium‑235 during the enrichment process. Since it is ‘leftover’, it is considered to be a ‘waste’ and treated negatively, which is wrong. However, DUHF is not a waste, but a resource.

We building 2nd depleted uranium hexafluoride (DUHF) processing unit. DUHF is a waste product of uranium enrichment. The unit converts DUHF into chemically safe uranium oxide powder. We turn waste into raw materials for MOX-fuel. Soon we be able to process 20k tons of DUHF a year pic.twitter.com/3SBKDJxyDA

— Rosatom Global (@RosatomGlobal) April 14, 2021

First, technology is progressing fast: DUHF can be re-enriched to obtain more uranium‑235. It used to be expensive or technically impossible, but not anymore. Rosatom provides depleted uranium re-enrichment services, including to foreign companies.

Second, DUHF is segregated into depleted uranium oxide and hydrofluoric acid. Depleted uranium oxide is used to produce MOX fuel for fast neutron reactors, while hydrofluoric acid is returned into the natural uranium enrichment cycle or reprocessed into anhydrous hydrogen fluoride and sold to chemical companies. Defluorination has one more advantage: uranium oxide is much easier and safer to store and handle. In fact, defluorinated DUHF is very much like uranium octoxide but does not contain uranium‑235.

Second, DUHF is segregated into depleted uranium oxide and hydrofluoric acid. Depleted uranium oxide is used to produce MOX fuel for fast neutron reactors, while hydrofluoric acid is returned into the natural uranium enrichment cycle or reprocessed into anhydrous hydrogen fluoride and sold to chemical companies. Defluorination has one more advantage: uranium oxide is much easier and safer to store and handle. In fact, defluorinated DUHF is very much like uranium octoxide but does not contain uranium‑235.

Depleted uranium is defluorinated in the UK, USA and France (see Uranium Deconversion Plants). Rosatom has been engaged in depleted uranium processing since 2009 when a DUHF processing unit with a capacity of 10,000 tons per annum was put in operation at Rosatom’s Electrochemical Plant in Zelenogorsk (Krasnoyarsk Krai). Its capacity is sufficient to reprocess almost the entire amount of DUHF left over after the uranium enrichment. The deconversion unit was produced by French Orano (then Cogema). For 10 years in operation, it reprocessed over 100,000 tons of DUHF.

TVEL has initiated two more projects. Two defluorination units with an annual capacity of 10,000 tons of DUHF each are planned to be installed at the Ural Electrochemical Plant in Novouralsk (Sverdlovsk Region). Engineering surveys and a feasibility study for the project began in August 2020.

The Electrochemical Plant in Zelenogorsk is constructing a building and infrastructure for its second unit with a capacity of 10,000 tons per annum. It will also be supplied by Orano and is planned to be launched in 2023.

Rosatom Group companies have accumulated nearly 1.2 million tons of DUHF by now. The new deconversion units at the two plants will help dispose of the DUHF stock, presumably by 2057.

“When the closed nuclear fuel cycle becomes a reality, it will solve a number of very important tasks. “First, we will have a much larger resource base for the nuclear energy industry. Second, we will be able to recycle spent nuclear fuel instead of storing it. Third, we will dispose of accumulated DUHF stocks by using them in nuclear fuel fabrication. What is more, development of recycling technologies in the nuclear industry is fully in line with Responsible Production, one of the UN Sustainable Development Goals,” noted Alexander Ugryumov, Vice President for R&D and Quality at TVEL.

Rosatom fuel division TVEL is one of the world’s largest suppliers of nuclear fuel. TVEL is the monopoly supplier of nuclear fuel to all Russian NPPs, ship and research reactors of Russia. TVEL fuels nuclear power plants in 15 countries, or every sixth power reactor in the world.