Power Engineering at Fifteen

back to contentsIn late March 2021, AtomEnergoMash (AEM), Rosatom power engineering division celebrated its fifteenth birthday. This article will tell you more about one of Rosatom’s most important divisions — its companies, R&D institutions, latest achievements, and plans for the future.

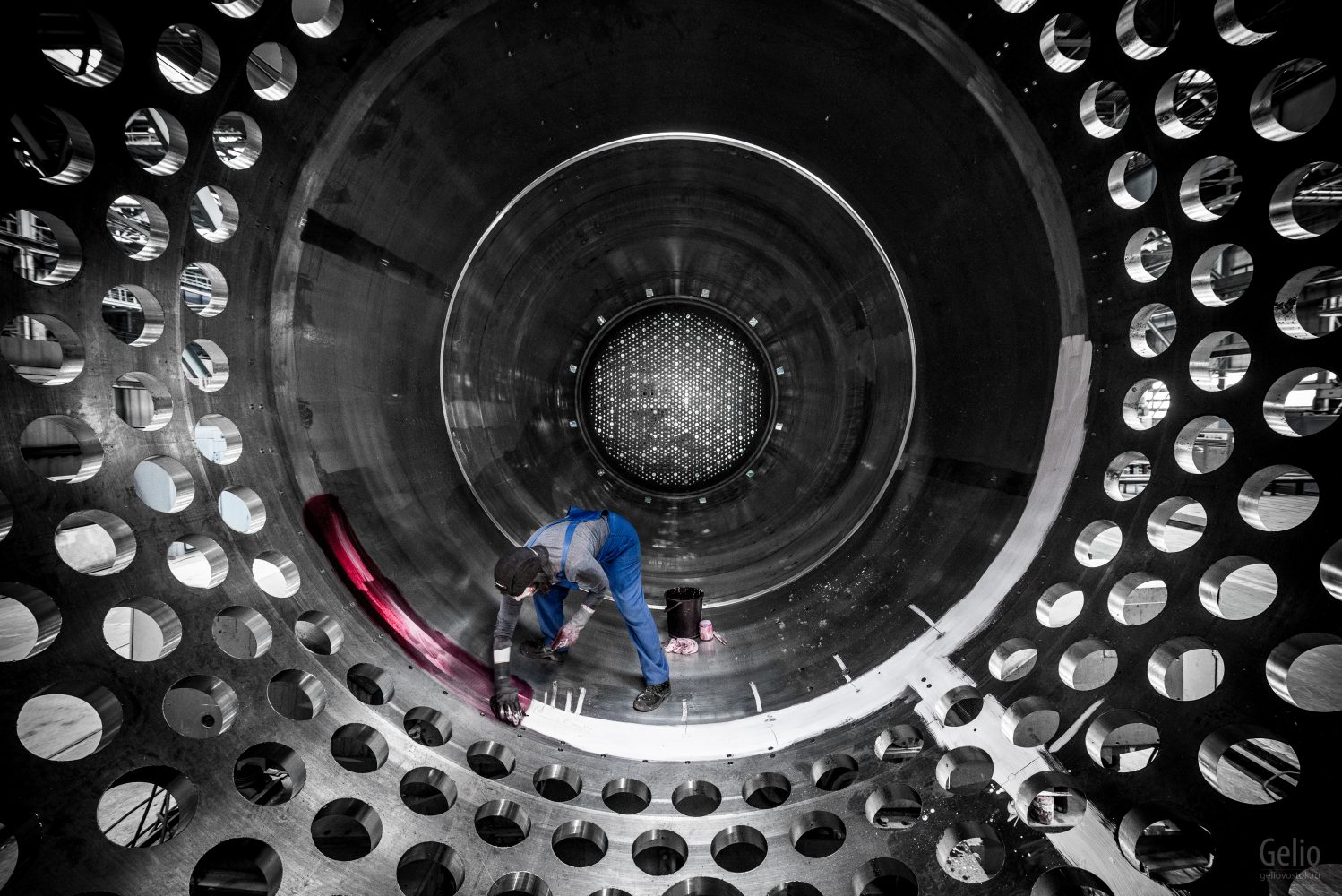

“If you need anything big and made of steel, we are always there,” says AEM CEO Andrei Nikipelov. The company specializes in manufacturing heavy industrial equipment, such as reactor pressure vessels — each of them weighs 320 metric tons, which is twice as much as a Boeing 747 aircraft. Two halves of the RPV should match each other with a tolerance of less than 1 mm. Welding them together takes 10 days. The reactor itself consists of a hundred of different-size components and requires 768 process operations and about two years to be manufactured. For example, the reactor for Rooppur Unit 2 in Bangladesh was made in 650 days, but AEM keeps optimizing its processes to reduce the production time.

The division brings together major power engineering companies, including production facilities and R&D centers. Located in Russia, the Czech Republic, Hungary and other countries, AEM production facilities put into practice what has been developed by the scientists and researchers studying properties, applications and processing technology of different materials.

Rosatom’s power engineering division is capable of the end-to-end supply of machinery and equipment for the nuclear and turbine islands of nuclear power plants. AEM takes part in the construction of all new Russian-designed nuclear power plants across the globe. The division has produced equipment for the Kudankulam (India), Rooppur (Bangladesh), Akkuyu (Turkey) and Kursk II (Russia) plants. It is now in the process of making machinery for two Chinese nuclear generating stations (Tianwan and Xudabao). The work is underway to manufacture equipment for turbine islands based on the Arabelle half-speed turbine technology. AEM companies also take part in upgrading power reactors in operation.

In 2020, AtomEnergoMash set a historical record, having produced three RPVs and 18 steam generators. With new nuclear power plants planned to be constructed, the company will increase its output in the future.

In 2020, AtomEnergoMash set a historical record, having produced three RPVs and 18 steam generators. With new nuclear power plants planned to be constructed, the company will increase its output in the future.

AEM also operates in shipbuilding and supplies core equipment for Rosatom’s icebreakers. Its subsidiaries manufacture reactors, heat exchangers, pumps and other equipment for Project 22220 nuclear icebreakers, including Arktika (already commissioned), Sibir, Ural, Yakutia and Chukotka (under construction). They will also produce RITM 400 reactors, steam turbines and all associated systems for Lider (Leader) icebreakers. The division is also involved in Rosatom’s stand-alone generation projects (floating nuclear power plants and small modular reactors).

Foreign companies are interested in partnerships with AtomEnergoMash in shipbuilding. Late April, AEM signed a memorandum of intent with the Swiss company ABB, a large global supplier of marine electrical equipment, including Azipod steerable propulsion systems. The parties agreed to join their efforts in setting up production of marine propellers at the facilities of Rosatom’s power engineering division.

“We plan to supply complete marine propulsion systems, from engine to propeller. These are the most demanding parts and components, so they are usually made of special steel grades that meet the most stringent requirements. Not many companies in the world have the competencies needed for that,” Andrei Nikipelov shared plans for the future.

Non-nuclear businesses are also of interest for AEM. In 2020, the division completed pilot tests of the first Russian-designed and produced pump for liquefied natural gas. The pump passed the tests and was put into operation. Pumps of this kind are used at commercial LNG production facilities. The company continues to build Europe’s first test facility for the equipment of medium and large-sized LNG plants. The test facility is being installed at Rosatom’s Efremov Research Institute and will be finished later this year.

As part of the Clean Country Russian federal program, AtomEnergoMash has partnered with the Swiss-Japanese company Hitachi Zosen Inova to build waste incineration plants in Russia and supply equipment for similar plants abroad. In 2020, the division shipped several superheaters for steam boilers of the Riverside waste-to-energy plant in the UK.

What you have read above is far from being a complete list of competencies the power engineering division possesses.

“We are entering a phase of rapid growth. Next year, we plan to make around RUB 113–115 billion in total revenue and bring it up to RUB 150–156 billion in 2023–2024. We expect our work load to peak every year, but the sharpest rises should happen in 2023–2025 — this is when we will have to solve the most difficult tasks,” Andrei Nikipelov sets out plans for the company.

AtomEnergoMash companies

1. Central Research Institute for Machine Building Technology (CNIITMASH)

2. OKB Gidropress

3. OKBM Afrikantov

4. AEM Technologies

5. Central Design Bureau of Machine Building

6. Sverdlovsk Chemical Engineering Research Institute (SCERI or SverdNIIKhimMash)

7. ZiO Podolsk

8. Atommash (Volgodonsk branch of AEM Technologies)

9. Petrozavodsk branch of AEM Technologies

10. Turbine Technology AAEM

11. ATM

12. ARACO (Czech Republic)

13. Ganz EEM (Hungary)