Breaking Into New Nuclear

back to contentsThe Russian nuclear power sector will switch over to the closed fuel cycle technology by the mid-century. Rosatom is busy developing all the key components for this technology, including innovative reactors, fuel, and radioactive waste management solutions.

The closed nuclear fuel cycle needs two types of power plants, those with pressurized water reactors and those with fast neutron reactors. Their combination will make nuclear a renewable source of energy and produce almost no waste.

The latest developments in this field were discussed this autumn at the New Nuclear Energy conference.

Alexander Lokshin, First Deputy Director General for New Products at Rosatom, emphasized that the new — both fast and thermal — reactors would belong to the fourth safety generation and listed their main criteria, such as unlimited fuel supply, non-proliferation compliance, high efficiency, increased safety, and minimum waste. He also outlined the VVER design evolution trajectory through the reduction of construction time and cost, higher efficiency, possibility of operation with 100 % MOX core, and improvement of load following capabilities.

The key competencies for closing the nuclear fuel cycle are brought together under the umbrella of the Proryv (Russian for Breakthrough) Project. This project deals with the development of three fast reactor designs: lead-cooled BREST-OD‑300 and BR‑1200 and a sodium-cooled BN‑1200M. The main solutions for these three designs include an integrated primary circuit layout, an isolation barrier in the vessel, a passive air heat exchanger for residual heat removal from the primary circuit, and a liquid-metal coolant with a high boiling point.

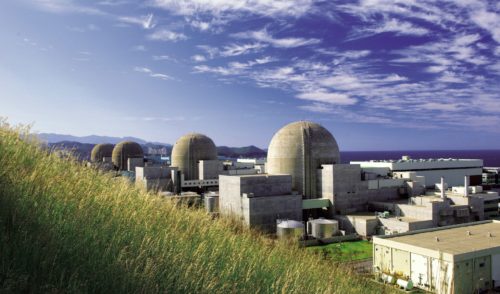

One of them, the 300 MW reactor BREST-OD‑300, is already being constructed at the site of the Pilot Power Production Facility (abbreviated ODEK in Russian) in the Tomsk Region. The first concrete for the reactor was poured in 2021; the commissioning deadline is set for 2027. Apart from the reactor, ODEK includes a fuel fabrication module (to be commissioned in 2024) and a fuel reprocessing module (to be commissioned in 2030). ODEK is intended to demonstrate the viability of closed fuel cycle technology. If the facility is proved viable, a commercial power plant will be built to follow ODEK. Currently under design, it will have an increased capacity and improved performance.

Fuel

Rosatom’s fuel division TVEL is working on a wide range of solutions aimed at closing the nuclear fuel cycle. Spent fuel from some nuclear reactors will be used as feedstock for the production of fresh fuel for other reactors.

TVEL has developed a technology for the production of regenerated uranium fuel for RBMK and VVER reactors. This fuel is supplied on a regular basis to Kola NPP Unit 2 in the Murmansk Region. A decision has been made to convert Novovoronezh II and Leningrad II power units with VVER‑1200 reactors to regenerated uranium fuel by 2027–2028.

An even more effective Russian solution for closing the fuel cycle is the uranium-plutonium REMIX fuel for VVER reactors. This fuel grade is being piloted for the second 18‑month cycle in the VVER‑1000 reactor at Unit 1 of the Balakovo NPP. REMIX fuel contains a mixture of enriched uranium with the uranium and plutonium separated from spent nuclear fuel. This technology makes it possible to reuse both plutonium and residual uranium‑235. Compared to the West European counterpart, a mixed uranium-plutonium fuel for light water reactors, REMIX can be used to load the full core and, when spent, be recycled multiple times, which is its indisputable advantage.

The closed fuel cycle will mostly benefit fast neutron reactors as they are more ‘omnivorous’ in terms of fuel and fissile materials. In mid-November 2023, the BN‑800 reactor at the Beloyarsk NPP was fully converted to mixed uranium-plutonium oxide (MOX) fuel. The innovative BREST-OD‑300 reactor, which is under construction in the Tomsk region at the site of the Siberian Chemical Plant, will operate on dense uranium-plutonium nitride (SNUP) fuel.

The production of MOX and SNUP fuels makes it possible to involve depleted uranium into the nuclear fuel cycle, gradually eliminating its accumulated stockpiles, while MOX fuel uses highly radioactive plutonium obtained by reprocessing spent nuclear fuel from VVER‑440, VVER‑1000 and BN reactors.

The next step is to manufacture experimental MOX fuel assemblies containing minor actinides (americium and neptunium), the most radioactive and toxic elements in irradiated nuclear fuel, to be loaded into the BN‑800 reactor. Thus, Russian nuclear engineers will be the first to leverage another competitive advantage of fast reactors and burn minor actinides instead of storing them in deep geological repositories as nuclear waste.

While the construction of the BREST-OD‑300 reactor is underway, researchers are working to provide justification for the SNUP fuel with a gradual increase in its burnup. Rosatom scientists are also solving a number of tasks to finalize and improve the SNUP fuel production technology to be employed at the ODEK fuel reprocessing module.