Year 2023 in Review

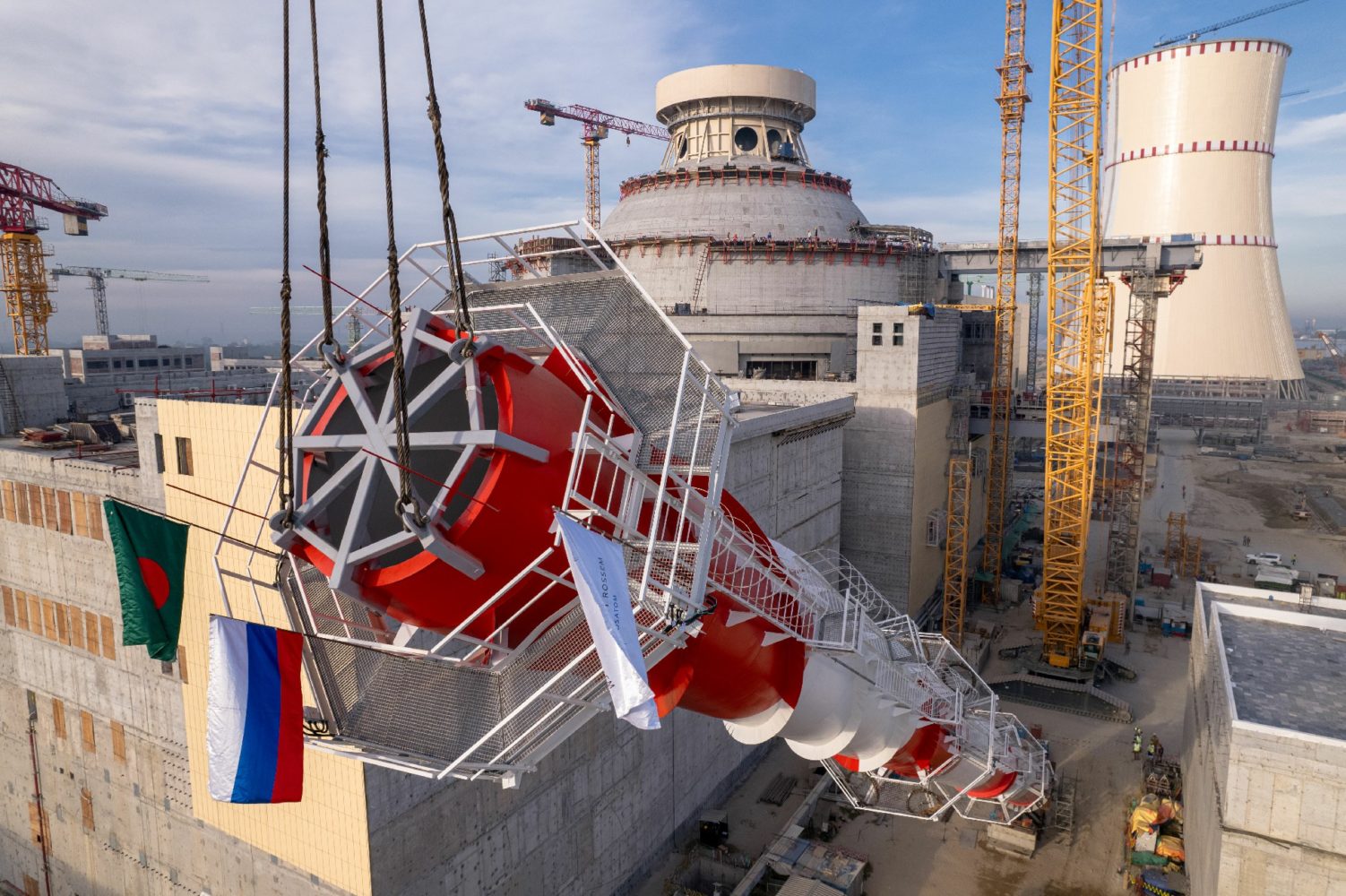

back to contentsThe first delivery of fresh nuclear fuel to the construction site was undoubtedly last year’s key milestone for the Rooppur NPP. Bangladesh joined the ranks of emerging nuclear nations. Both of the plant’s two reactors were built on, and even ahead of, schedule. Much attention was paid to training the staff for the soon-to-be-built nuclear facility. Let us take a look back at the 2023 key events.

Construction

On-site construction works were going right on schedule throughout the year. In February, welding operations were completed on the reactor pipes connecting primary coolant equipment of Unit 2.

“When the nuclear power plant is in operation, coolant heated to 320 °C circulates in the primary circuit, so pipe welding is a critical process. Each weld passes seven checks at different stages of the process to ensure its quality and safety,” Alexei Deriy, ASE Vice President and Director of the Rooppur construction project, explained.

In the spring, concreting of the outer containment was finished 45 days earlier than planned. The entire process took 110 instead of 155 days. As a result, external and internal steel structures of the passive heat removal system (PHRS) deflector were also installed sooner than scheduled.

In March, a pressurizer was installed in the reactor building of Unit 2. It is designed to create and maintain the required pressure in the primary coolant circuit of the reactor.

In April, a passive core flooding system (PCFS) was installed at Unit 2. The system removes afterheat in a loss-of-coolant accident in the primary circuit. Also in April, the first cubic meter of chemically demineralized water was produced at the plant construction site. VVER reactors use deionized water as a coolant and a neutron moderator.

In May, a core barrel was installed in the reactor building of Unit 1.

In June, the workers finished concreting the inner containment dome at Unit 2. The inner containment makes the reactor building airtight and serves as a support for pipeline penetrations and a polar crane, which is used for reactor maintenance operations. Also in June, the reactor of Unit 1 passed a fit-up assembly test.

In July, the Bangladesh Atomic Energy Regulatory Authority, the local watchdog, issued a nuclear fuel management, storage and transportation license to the Rooppur NPP operator, the Bangladesh Atomic Energy Commission (BAEC).

A ventilation pipe was installed in the reactor building of Unit 1. The workers used a powerful crane to do this extremely complicated task.

In August, a gantry crane was installed at Unit 1. It is used to handle super-heavy equipment and move fresh and spent nuclear fuel during the plant operation. Installation of eight heat exchangers for the passive heat removal system (PHRS) was also completed in August.

Erection of the ventilation pipe was finished in the controlled-access workshop building. Two out of six diesel generators were installed at the backup diesel power plant. It is designed to supply power needed to shut down and cool the reactor in case of emergency.

The installation of equipment was also completed at the chemical desalination plant of the Rooppur NPP. The installation process lasted five months.

Finally, on October 5, the first batch of fresh nuclear fuel arrived at the Rooppur NPP site from Russia.

“Today marks a new stage in the development of Russia-Bangladesh relations. With the first arrival of nuclear fuel, the Rooppur NPP becomes a nuclear facility and the People’s Republic of Bangladesh gets the status of a country that possesses civil nuclear technology,” Rosatom Director General Alexey Likhachev said.

Bangladesh Minister of Science and Technology Yafesh Osman noted that the entire country had been eagerly waiting for that momentous event. IAEA Director General Rafael Grossi stressed that the Rooppur project was a remarkable example of how non-nuclear countries could deploy nuclear technology.

Nuclear fuel for the Rooppur was delivered from Russia by special flight to the Hazrat Shahjalal International Airport in Dhaka and then by road to the Rooppur site.

Education

Along with building the nuclear power plant, Rosatom also helps Bangladesh train operating and maintenance personnel for the facility. Since 2019, a total of 1,643 employees from Bangladesh have been trained at the Novovoronezh NPP, including 367 people in 2023. Altogether, 1,895 Bangladesh professionals will complete training in 2019–2024. Their course comprises theory classes, laboratory training, simulator-based skill practicing, and on-the-job training at the nuclear power plant.

In May, a group of Bangladesh Army officers from the Rooppur NPP security squad took a two-week Security of Nuclear Facilities training course in Russia. The program included theory classes and also practical exercises held at a special training area of Rosatom’s Technical Academy. The Bangladesh Army has been ensuring security of the under-construction nuclear power plant since 2020.

In June, the Saint Petersburg branch of Rosatom’s Technical Academy held an IAEA international training course on preventive and protective measures against insider threats. The course was attended by professionals from 14 countries, including Bangladesh.

In August, a group of the Rooppur NPP security officers did a pilot training course on the security infrastructure management at Rosatom’s Technical Academy. In September, Ali Mohammad Hasmat, who will be Chief Engineer at the Rooppur NPP, completed a three-week internship program at the Novovoronezh NPP in Russia.