MCP: Fuel Transformations

back to contentsEmployees of the Mining and Chemical Plant (MCP) know well how to handle spent nuclear fuel to make it fresh again. This February, MCP is celebrating its 75th anniversary. This one-off plant, some of whose production facilities are located deep in the rocks above the Yenisei River, plays an important role in the development of a closed nuclear fuel cycle and the back-end management of spent nuclear fuel in Russia.

Where it all began

MCP traces its history back to February 26, 1950 when the USSR Council of Ministers adopted a resolution on the construction of an underground nuclear production site (Combine No. 815) in the Krasnoyarsk Krai. It became later known as the Mining and Chemical Plant.

The plant used to operate three successively constructed uranium-graphite reactors code-named AD (1958), ADE-1 (1961), and ADE-2 (1964). The plant also has a radiochemical facility for the reprocessing of spent nuclear fuel and extraction of weapons-grade plutonium. It was decided to place the reactors deep in rock shafts to protect them against a possible attack.

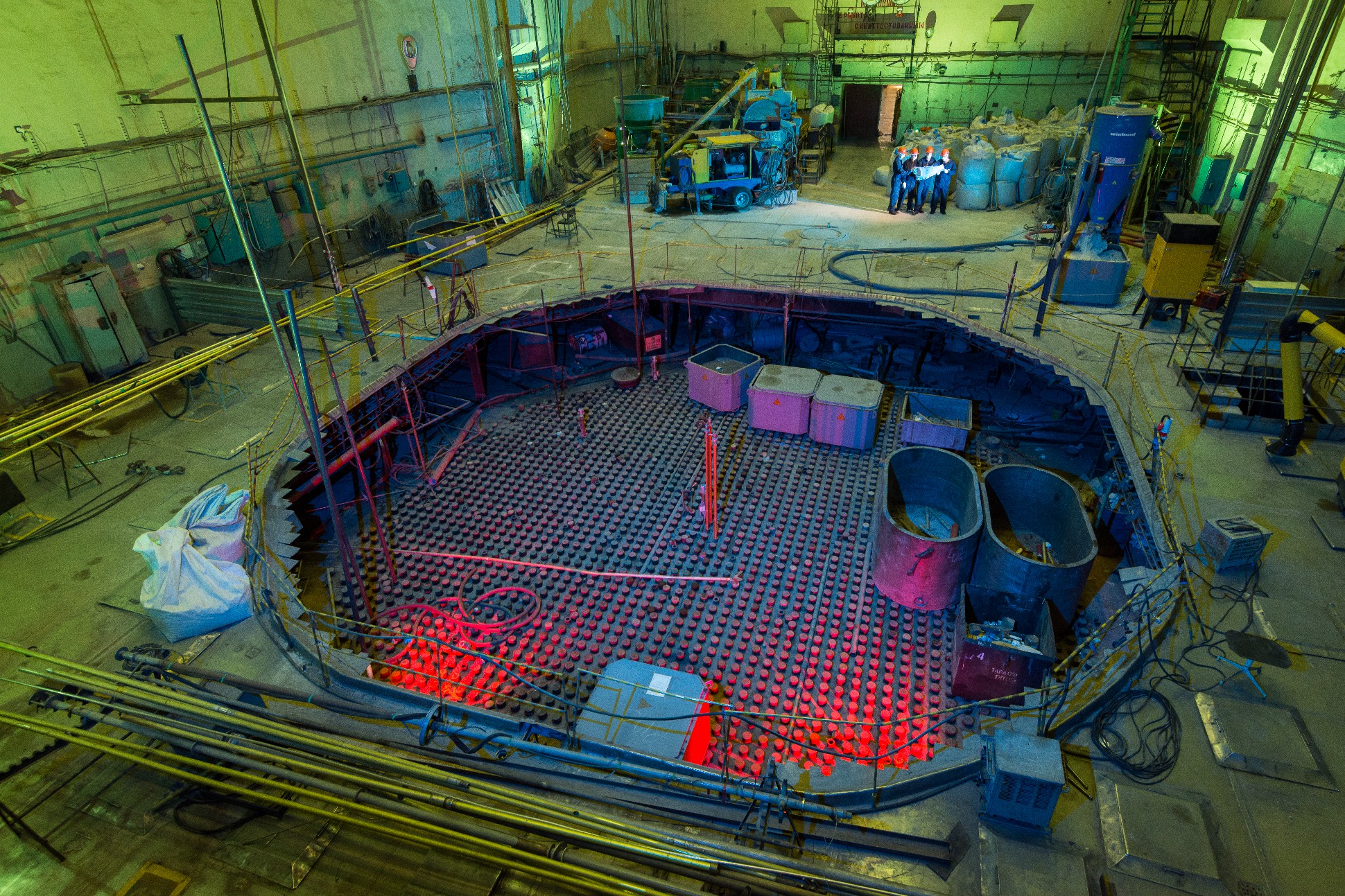

AD and ADE-1 were single-purpose reactors used for plutonium production only. ADE-2 was the world’s first dual-purpose reactor, which also generated electricity. It was connected to an underground thermal power plant that used to supply heat to the nearby town of Zheleznogorsk for almost half a century. ADE-2 was shut down for decommissioning as late as 2010.

The first two reactors were shut down back in 1992. In 2023, they were decommissioned with an ‘in-situ disposal’ option (the reactor and some adjacent premises were filled in with barrier material). This drew down the curtain over the production and extraction of weapons-grade plutonium, the primary task performed by MCP in the 20th century.

Modern days

MCP’s current mission is to develop an end-to-end technology for managing irradiated fuel from power reactors and closing the nuclear fuel cycle.

Its key goal for this year is to commission the second fuel reprocessing facility for a pilot spent fuel management center. The first facility built in 2015 is a chain of hot cells and an analytical laboratory that studies spent fuel reprocessing and waste management techniques.

“With the second facility in place, we will be able to reprocess spent nuclear fuel on a commercial scale. The new technology will make it possible in the future to stop accumulating and minimize burying radioactive waste, and bring us closer to the deployment of Generation IV energy technologies,” says Vasily Tinin, Director for Radioactive Waste, Spent Nuclear Fuel and Nuclear Decommissioning Policy at Rosatom.

In the next few years, the spent fuel management center will become a globally unparalleled test site for spent fuel management technologies. The test results obtained will be used for the purpose of designing large-scale radiochemical production facilities.

Another area of focus is the production of uranium and plutonium mixed oxide (MOX) fuel for the BN-800 fast neutron reactor installed at the Beloyarsk NPP. This fuel makes it possible to use plutonium as a feedstock material for the fabrication of fresh fuel, which can be later recycled. The MOX fuel production facilities were built in 2011–2014. The manufacturing line is automated and placed in a chain of radiation protection enclosures and chambers. It ensures regular deliveries of MOX fuel assemblies for the refueling of the BN-800 reactor. Our readers should remember that BN-800 has been operating with a 100% MOX fuel core since 2022.

MCP is also working on a project that is of great importance for the environment. The project provides for the development of Russia’s first molten salt research reactor (MSRR). It is needed for the transmutation (‘burning’) of minor actinides, highly radioactive long-living transuranium elements that are formed during fuel irradiation. This would dramatically reduce the volume of waste and its half-life. R&D on the molten-salt reactor has been underway since 2020. Its concept design is ready, and researchers are studying the composition of salts, which will combine the functions of fuel and coolant, and testing structural materials for the reactor and its systems.

Another task related to the MSRR development is the decommissioning of the ADE-2 reactor and the underground cogeneration plant as the plant’s site is being prepared for the construction of the new reactor. In turn, the ADE-2 reactor room will be converted into a nuclear industry museum after the work is completed.

Photo by: MCP, Rosatom State Corporation, (Rosatom)