Akkuyu: Growing Higher and Wider

back to contentsThe Akkuyu NPP is one of the world’s largest construction sites. Equipment commissioning is underway at Akkuyu Unit 1, while construction and installation works are continuing at other units. Every month sees important events taking place at the site, bringing the plant closer to commissioning. Here is the latest news from the construction site.

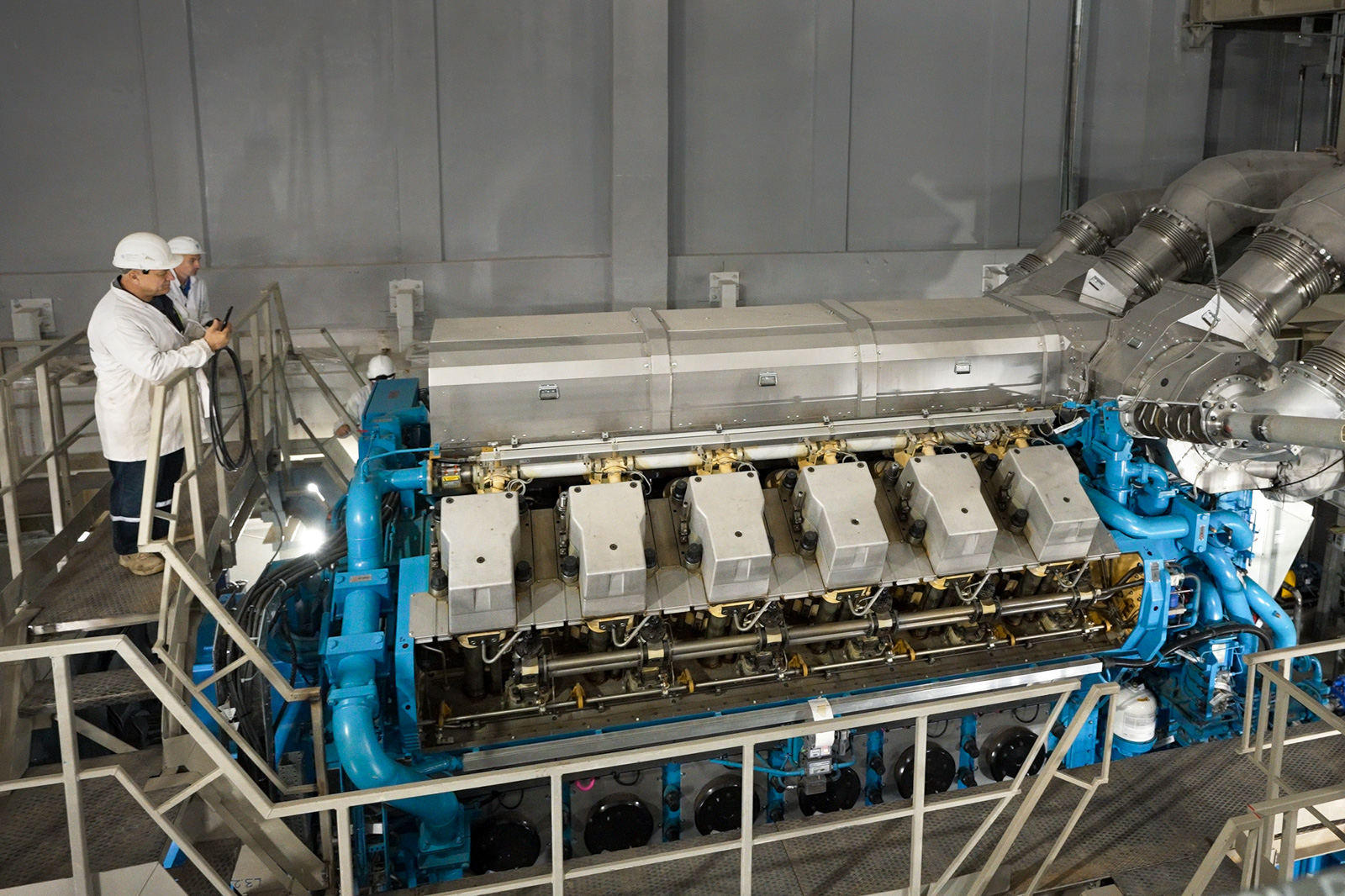

In late February, the first standby diesel power plant was put into operation at Akkuyu Unit 1. On-load tests are being carried out step by step to check its operability.

“Backup diesel power plants belong to the key components of the nuclear station safety systems. Each power unit of the Akkuyu NPP is equipped with three such power plants. They serve as an autonomous power source if the main power supply fails. Each of the three standby diesel power plants has a diesel generator as its core. Today we have turned on the first of them, a diesel generator of the normal operation standby diesel power plant,” said Andrey Zhukov, Deputy Director of the nuclear plant under construction and Chief Technical Officer at Akkuyu Nuclear JSC.

Each generator is installed in a freestanding building next to the main buildings of the power unit. Having a capacity of 6.3 MW each, three diesel generators installed at each power unit will together be able to supply all of its operating systems with power for at least 72 hours without refueling.

After being turned on, each generator will have to pass about 50 tests in various operating modes. As soon as the engineers make sure that all the systems of the generator are working reliably at rated power, it will be put in a standby mode and remain in it while the nuclear power plant is in operation. The standby diesel generators have a very short setup time: they need 15 seconds after receiving a signal to start supplying power. The startup process is fully automated. In addition, putting diesel generators in a standby mode is a prerequisite for the beginning of cold and hot functional tests on the reactor.

Higher and safer

In early March, workers installed the second tier of the inner containment shell (ICS) at the fourth unit of the plant. The ICS assembly blocks were manufactured using high-precision equipment to ensure compliance with the design parameters. After delivery to the Akkuyu NPP, they were assembled into a 12-meter-high ring on the consolidation site located near the reactor building. Then the assembled tier weighing more than 200 tonnes and having 44 meters in diameter was moved into the reactor building with the help of a crawler crane.

“We have gained solid experience in installing containment shells, so the lifting, moving and alignment operations take a few hours only. They are preceded by a painstaking job of assembling the sections into a single robust structure,” commented Sergey Butskikh, CEO of Akkuyu Nuclear JSC.

Power units with VVER-1200 reactors have a double – inner and outer – containment shell. Each ICS tier is made of a robust steel structure and specialty concrete. Together they make a tight-proof containment that reliably protects the reactor from any external impacts, including magnitude 9 earthquakes, tsunamis, hurricanes or their combinations.

The first hundred

In February, the Vostochny (Eastern) cargo terminal at the Akkuyu NPP site passed another milestone, having received the hundredth cargo ship since the beginning of its operation.

“Equipment and materials for the nuclear power plant keep arriving. The Vostochny cargo terminal is Akkuyu’s most important logistic facility as it ensures uninterrupted cargo deliveries by sea. Vessels from different countries come to the port, and today we are receiving the hundredth cargo ship. It has delivered switchgear and turbine components for different power units of the plant,” Sergey Butskikh said.

Port manager Okan Bozkurt pointed out that only vessels delivering cargoes for the Akkuyu NPP call at the Vostochny cargo terminal.

“The terminal’s berth is optimally designed to receive large-sized cargoes, construction materials and equipment, including reactor components. It will operate throughout the service life of the nuclear power plant. Pilotage and towage services are provided to all cargo ships when entering and exiting the Akkuyu Bay and during mooring operations,” Okan Bozkurt said.

The Vostochny cargo terminal has been operating since 2019, having received over 100,000 tonnes of cargo. The port territory is a customs zone and a border checkpoint of the Republic of Turkey. All cargo handling operations are carried out in accordance with the Turkish national laws and Rosatom’s cargo transportation and acceptance standards.

Photo by: Akkuyu Nuclear JSC