Anniversary for Two Reactors

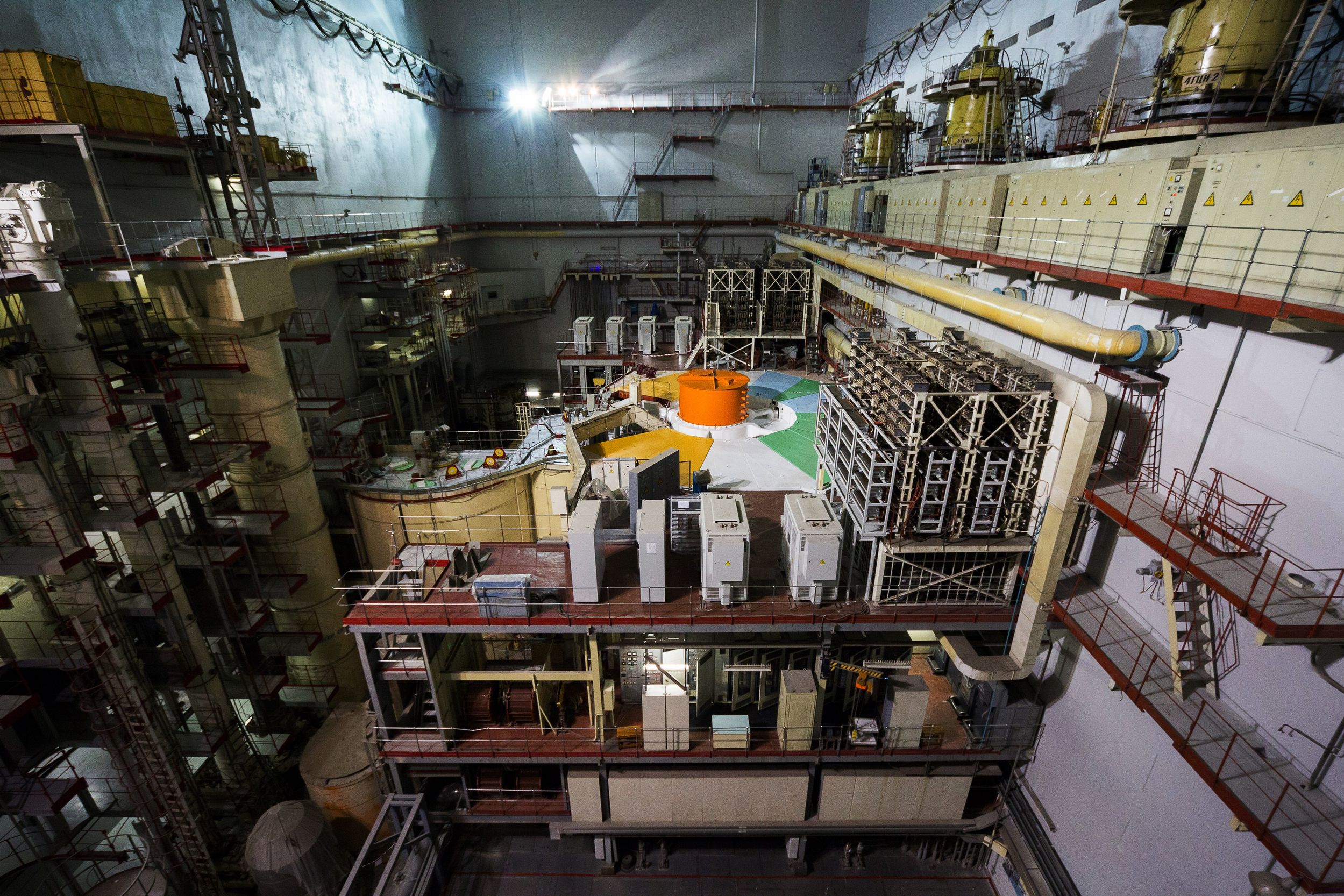

back to contentsThis year, two fast-neutron reactor units at the Beloyarsk Nuclear Power Plant are celebrating anniversaries. Unit 3 with the BN-600 reactor was connected to the power grid in 1980. Unit 4 with the BN-800 reactor was brought online in 2015. Along with generating electricity, these reactors contribute to developing a closed nuclear fuel cycle and implementing Generation IV concepts, which involve reprocessing irradiated fuel assemblies, manufacturing fresh fuel from them, maximizing the use of energy contained in natural uranium, and minimizing waste.

BN-600 and BN-800 are the largest fast-neutron reactors in the world. Both units use sodium as a coolant and rank among the safest and most reliable nuclear reactors globally.

BN-600

The BN-600 has been safely generating electricity, while also being used to test new materials and nuclear fuel for future reactors. For instance, an experimental fuel assembly OS-4 containing mixed uranium-plutonium nitride (MUPN) fuel is being prepared for testing. It is planned to achieve a higher burnup level during irradiation of this experimental assembly.

Also awaiting tests are three experimental assemblies labeled KETVS-MAK. They contain axial-interlaid mixed oxide (MOX) fuel, with the size of fuel rods intended for the BN-1200 reactor (now under design). A distinctive feature of these fuel rods is that their fuel columns include segments with the so-called breeding material. Collectively, these segments form a horizontal layer inside the reactor core, dividing it into two sections. This core structure is assumed to reduce radiation damage to the fuel cladding while maintaining the required fuel burnup. The concept has been theoretically validated in several countries but will be applied in practice for the first time in the Russian BN-1200M. This is a 1,200 MW fast-neutron reactor to be constructed at the Beloyarsk Nuclear Power Plant.

Unit 3 with the BN-600 reactor is currently undergoing scheduled preventive maintenance and retrofitting. “We will load 107 fresh fuel assemblies into the BN-600 core. Among the assemblies to be replaced, three contain MUPN fuel. These fuel assemblies have been for almost a year in the operating reactor. Further research will provide information on the behavior and condition of this new fuel type in prospective Generation IV power units — BN-1200M and BREST,” said Ilya Filin, acting chief engineer of the Beloyarsk Nuclear Power Plant.

In addition to refueling, a critical task will be replacing eight evaporators in steam generator No. 4. This is the final stage of work to extend the service life of Unit 3 until 2040, as required by the Russian watchdog Rostekhnadzor. The maintenance program also provides for major repairs on the reactor’s main circulation pump and 24 valves in the sodium circuit. Additionally, electromechanical relay protection and automation devices in the power output circuit of turbine generator No. 5 will be replaced with microprocessor-based equivalents. The maintenance is scheduled to be completed in autumn 2025.

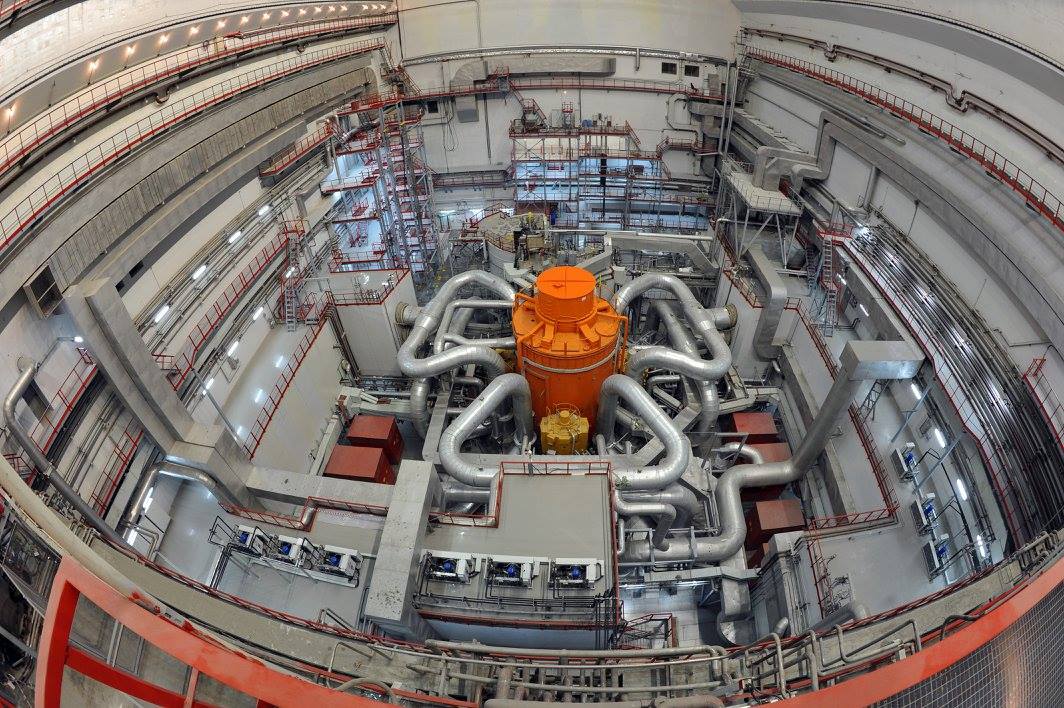

BN-800

Unit 4 holds special significance for the development of both the Russian and global nuclear industries as its fast-neutron power reactor is currently the only one in the world operating fully on mixed uranium-plutonium oxide (MOX) fuel. Like its BN-600 counterpart, the unit is currently undergoing scheduled preventive maintenance, during which 181 assemblies in the reactor core will be replaced with fresh fuel.

In addition, supplementary pumps, pipelines, and valves will be installed in the stator and rotor cooling systems of the turbine generator. After installation, each system will have two backup pumps, increasing the safety of the power unit’s operation. Also, the staff will replace an intermediate heat exchanger and a circulation pump motor, and conduct in-service inspections of the metal structures and components.

The BN-800 is also involved in validating new types of fuel. In July last year, three fuel assemblies with minor actinides added were loaded into the reactor. Americium-241 and neptunium-237 are among the longest-lived and most radiotoxic isotopes present in spent nuclear fuel. The performance and condition of these assemblies in the BN-800 core are expected to experimentally confirm the feasibility of eliminating minor actinides on an industrial scale. “This advantage of fast-neutron reactors allows reducing radioactive waste,” noted Ivan Sidorov, Director of the Beloyarsk Nuclear Power Plant.

BN-1200

The next step for the Beloyarsk Nuclear Power Plant is the construction of a new, fifth power unit with the BN-1200M reactor. This will be the first commercial reactor to become part of a Generation IV power system. Two core configurations are being considered for the BN-1200M, either with uranium-plutonium oxide fuel similar to that used in the BN-800 reactor or with uranium-plutonium nitride fuel planned to be loaded into the BREST-OD-300 reactor. The latter is now under construction in Seversk, Tomsk Region.

This July, Rosatom Director General Alexey Likhachev gave a go-ahead to the preparations for the start of construction work. “With the start of work on Unit 5, Beloyarsk reaffirms its status as a leader in the development of fast neutron reactors. It will be an integral part of our cutting-edge project to create a closed nuclear fuel cycle. Advancing in the field of fast reactors will allow us to strengthen the global leadership of Russian nuclear technologies,” Alexey Likhachev said at the time. First concrete pouring for the foundation of the main building of Unit 5 is planned for 2027.

The operation of these sodium-cooled reactors draws much interest from nuclear professionals in other countries. A recent example is the visit of a Chinese delegation to the Beloyarsk Nuclear Power Plant in July of this year. The guests toured the reactor compartment, turbine hall, and control room of Unit 4, visited the training center, and discussed potential cooperation.

Photo by: Rosenergoatom, “Strana Rosatom” Newspaper, Beloyarsk NPP