A company of the future

back to contentsConstruction on Khiagda’s main site was started in 2010 as part of ARMZ investment program. In the summer of 2014, the main production unit, storage facilities for chemicals and finished products, the transformer substation, compressors and the fire station were launched in test mode. A commission permit was issued in May 2015, and the work began to prepare the commissioning of power and water supply networks and sodium nitrite production and storage facilities.

“The launch of the sulfuric acid plant is this year’s key achievement. Its capacity is sufficient to cover all the production needs despite that in-situ leaching technology requires large amounts of this chemical. Incorporating the latest innovative technologies, the on-site sulfuric acid plant opens broad prospects in terms of economic effects. The plant was at the core of our investment program. Total investments in the production facilities and infrastructure amounted to nearly four billion rubles,” explains Khiagda CEO Alexei Dementiev.

The groundbreaking ceremony took place in March 2010. By that time, the ARMZ Engineering Center had selected the site, conducted site surveys and developed a project design. After the federal regulator Glavgosexpertiza gave its approval to the project, the construction began. Intertest was selected as general contractor.

Ground works and road construction were completed in 2010–2012, with the latest technologies used to minimize environmental damage. A project office involving Khiagda designers, constructors and leading experts was established to coordinate the construction process. Weekly revisions allowed immediate response to urgent issues, contractor coordination and equipment supply.

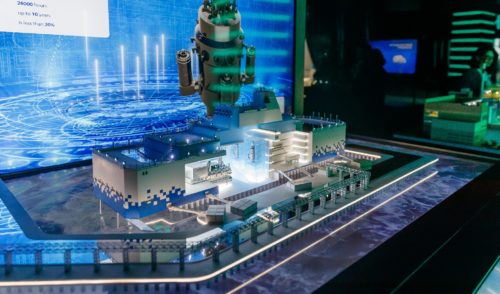

The 5th of September was marked with the plant opening ceremony. “It is symbolic that this remarkable event is happening these days when we celebrate the 70th anniversary of the Russian nuclear industry. Here we are, literally at the very first link of our entire value chain, at a rich deposit and a source of power and strength for the whole nuclear industry,” said ARMZ CEO Vladimir Verkhovtsev.

According to Khiagda’s chief geologist Andrey Gladyshev, the main production site is located in the heart of the Vitimskoye uranium district with 350,000 tons of uranium resources, including 250,000 tons suitable for in-situ leaching. The Khiagdinskoye, Istochnoye, Vershinnoye, Tetrakhskoe, Dybrynskoe, Namaruskoe, Koretkondinskoye and Kolichikanskoe deposits in the Khiagdinskoye ore field are all either under development or in the development planning stage.

The rated capacity of the plant is 110,000 tons of sulfuric acid monohydrate annually, or 324 tons of sulfuric acid per day. Sulfuric acid is made from gaseous sulfur by double-catalyst process (with double absorption). All the leading uranium manufactures have used this technology for the last 30 years.

The on-site plant will reduce transportation costs as sulfur granules will be delivered to the site instead of sulfuric acid. Much more important is a possibility of increasing uranium output.

“Now, when all the facilities are in operation, we are able to step up the uranium production. We are now developing the Khiagdinskoye deposit, with Istochnoye and Vershinnoye to follow in 2015–2018. In 2014, Khiagda produced 442 tons of uranium. The plan for 2015 is 508 tons, with the annual output of 1,000 tons to be reached by 2018. Further plans are to produce up to 2,000 tons per year,” Vladimir Verkhovtsev said.