First Plant, First Parts

back to contentsOn August 20, AEM Technologies (a subsidiary of Rosatom’s engineering division) shipped a pressure vessel for the VVER‑1200 reactor and the first out of four steam generators.

These key components were manufactured at Volgodonsk-based Atommash, the largest nuclear engineering and production facility in Russia.

Transportation of the heavyweight components (the RPV and the steam generator weigh 333.6 and 340 tonnes respectively) is a very complex logistics task. They were first transported, each unit separately, on a special truck to the cargo port on the bank of Tsimlyansk Reservoir (Don River) in Volgodonsk. Roads were closed out and power transmission lines de-energized along the transportation route. Then the equipment will be transported by water to Novorossiysk and then, through the Black Sea and the Suez Canal, to the construction site in Bangladesh.

Producing top-quality equipment and delivering it on time are priorities of Atommash, Atomenergomash’s CEO Andrei Nikipelov said commenting on the event, “Despite restrictions caused by the coronavirus pandemic, we met the time schedule in shipping the first RPV for the Rooppur Nuclear Power Plant. Our equipment has a long way to go — 14,000 kilometers by sea to arrive at the construction site of the first nuclear power plant in Bangladesh by the end of the year.”

Representatives of Bangladesh attended the shipping ceremony. Dr. Syed Masud Rana, the leader of the inspection team of the Bangladesh Atomic Energy Commission (BAEC), noted that the parties stay in close cooperation and solve all the matters quickly and efficiently, “Atommash does its best to meet the production and shipping schedule, so we are satisfied with its performance. The team of inspectors working at the production facility changed every three months throughout the last two years. The last team had to spend half a year in Russia because of the pandemic. I spent three months in Volgodonsk last year and six months in 2020. I like Russian people and has grown fond of the Russian cuisine,” Dr. Rana said.

Atomenergomash will manufacture more than 14 types of equipment for the Rooppur NPP, including equipment for the nuclear island (reactors, steam generators, primary coolant pumps, pressurizers, components for the emergency core cooling system and passive safety systems) and the turbine island (high pressure heaters, vacuum pumps, condensate pumps, feeding pumps, separating and reheating systems of the turbine plant). In 2018–2022, the company will produce and ship more than 13,000 tones of exclusive machinery.

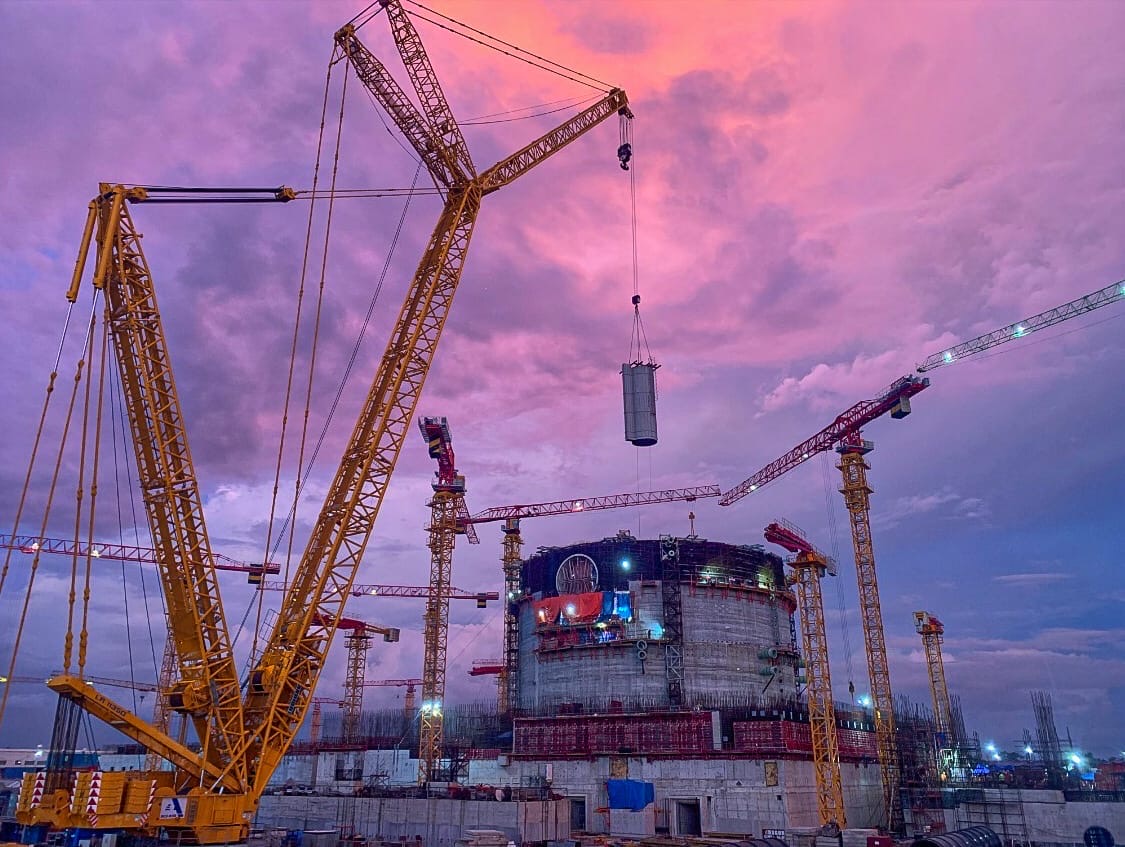

The work is in full swing at the Rooppur construction site. Installation and concreting work is completed at Tier 3 of the internal containment of the Unit 1 reactor building. It took only 118 days to do the task that required laying 2,000 cubic meter of concrete mix.

Construction of the third tier of the internal containment structure is one of the most important milestones passed in 2020. It was completed in full accordance with the project schedule. New installation and concreting techniques were employed to improve the overall performance and accelerate completion of the task.

The first nuclear power plant in Bangladesh will have two VVER‑1200 reactors with a total power capacity of 2,400 MW. Their design life is 60 years and can be extended. Nuclear power plants with VVER‑1200 reactors are characterized by increased safety and thus considered to belong to Generation 3+ power units. Higher safety is achieved using passive safety systems that need no human involvement and remain operational even if the plant is experiencing a blackout.