Construction gains momentum

back to contentsBaltic NPP

The main construction works on the Baltic NPP site have been developed this year. One of the main stages is development of the foundation pit for the construction of the main buildings of Baltic NPP unit # 2. Builders have moved over 700,000 cubic meters of soil. The depth of excavation is 14 meters. The process involved more than 80 units of modern heavy equipment – trucks and excavators.

The following stage of construction was shipping of the pile assembly molten-core catcher of the first unit with the weight of 739 tons. The device manufacturer is Energomash (Volgodonsk) – Atommash LLC. The off-gauge part of the catcher was shipped by water: first it took its way over the rivers Don, Volga and Neva, than over the Gulfs of Finland and Kaliningrad up to the port of Ust-Luga. From there part of the cargo was transported by road, and other part – by water canals. The molten-core catcher, being the “know-how” of Russian nuclear scientists, was first installed at Tianwan Nuclear Power Plant (China). Located at the bottom of the reactor cavity, the large metal structure filled with special sacrificial material, which in case of emergency can exclude the impact of the molten fuel on a concrete base containment and won’t leak radiation into the environment.

Other significant event is vertical cladding assembly of the foundation plate in the power unit #1 building. The concrete lining has been completed on the auxiliary building along with formation of the pit for “nuclear island” buildings.

Today the work has started on more than 20 sites of the main buildings and 26 temporary objects. The work on two units is run by 16 contractor organizations. According to the director of “NIAEP” Valery Limarenko, next year the pace of work will keep growing and the scope of tasks will be increased by fifty percent minimum. The number of staff will also increase. “Currently the construction of the nuclear power plant involves more than 1,700 employees, more than 1400 of that number are workers,” – said the director of the Baltic branch of “NIAEP” Vyacheslav Makhonin. According to the contractor, in order to complete the current year program and provide the scope of construction and assembly works for the first half of 2013, the necessary project documentation needs to be issued into production. The launch of the first unit is planned for 2017, of the second – for 2019.

Rostov NPP

The supply of two auxiliary transformers to the Rostov‑3 construction field laid down the foundation for the new stage of construction. The transformers are designed for supplying electricity to the unit for their own needs. The specialists have already conducted all necessary preparations in order to install the transformers to their proper locations.

The large-size equipment also includes steam-generating units. The first one of the four generators arrived in May and is meant to serve for the power-generating unit #3, currently under construction. The equipment weighing over 85 tons, with the length of 15 meters and a diameter of more than 4 meters was produced by “ZIO-Podolsk Machine Building Plant” JSC.

In late October at the site of Rostov NPP the lifting and installation of the containment dome of the reactor power unit #3 was performed. The second tier of the containment dome weighing 165 tons and having 37 meters in diameter was mounted on the ground and raised to the containment. The next step was to organize “clean” area in containment zone and start the main equipment installation, which are reactor vessel, steam generators and main circulation pipeline.

Another control point of this year is the 45th mark lift slab of the reactor power unit #3 rigging. The completion of this work is scheduled for late 2012.

Two important events took place at the beginning of November – voltage supply for their own needs and installation of the second tier of containment dome of the reactor building unit #3 of Rostov NPP.

Another important event is arrival of the fourth steam generator designed for the power unit #3 to the construction site. After adjustment and testing of the polar crane is completed, the installation of heavy equipment of the reactor core power unit #3 will begin.

“Installation of the dome and voltage supply for their own needs is an availability measure for a power unit to conduct large-scale commissioning” – sums up the director of “NIAEP” Valery Limarenko.

Today the construction of power units switches to three shifts operation due to increasing speed and volume of works. The number of staff at the site is growing: in November there are more than 7,300 specialists at the construction site of two units, including nearly 6,000 workers. The launch of power unit #3 is scheduled for 2014, the launch of the fourth – for 2016.

SRO President Victor Opekunov:

Not everyone is allowed– Our construction sites are not a place for random companies which cannot provide the required level of competence, says president of SRO of nuclear industry Victor Opekunov.

– The price of errors is very high. That is why from the very first day of its existence SRO has been extremely demanding in terms of work permit which should not only meet the requirements of Government Decree #207, but at some points exceed them. We monitor the staff presence and level of training, state of the material and technical base, project management and quality management systems, control the performance of SRO standards as well as fulfillment of occupational health and safety legislation. The specific character of nuclear industry keeps everyone in good shape. The admission paper in your pocket is not yet a reason to relax. All companies, both planned or upon request, are regularly visited by representatives of Technical Supervision.

“We were the first in Russia to begin to check not only the requirements of the relevant organizations of SRO, but also standards compliance, technical regulations and observation of rules for construction works” – comments Opekunov. – There was one principle that we adopted immediately: checking should be friendly, but as unbiased as possible, the inspection acts should show the true situation on the sites. Our experts not only try to point out errors in right time, but also help to understand the situation. Basically every revision gives its prescriptions. Each month some members of SRO are expelled. In the last three years more than 120 members were fired.

Novovoronezh NPP

Construction of Novovoronezh NPP‑2 power units is going full bat. The launch of the first unit of Novovoronezh NPP‑2 is not far off – in 2014. The installation of large-sized equipment at the first unit started back in 2009 with melt trap assembly. In the second block the assembly of the trap started in 2010. At the same period of time took place the first equipment debark on the river pier built in Novovoronezh specially for supplies delivery to the construction site. The reactor vessel was also delivered by water in 2011. The same year builders started assembling the most powerful high-speed NPP turbine in Russia.

This year, in 2012, started the installation of the reactor vessel of the first power unit. Installation work on site was completed in September. An important event of the year was construction of a cooling tower of the power unit #1, with its diameter at the base about 130 meters. Builders started installation of internal support structures, consisting of 2,300 elements, along with irrigation system. The completion of the cooling tower is planned for late 2013. One cooling tower instead of two, as it used to be before on the NPPs of Russia, is now being constructed on the site. The design lifetime of the cooling towers is up to 100 years.

Besides that thermal insulation welded from steel plates was delivered from producer factory (“Petrozavodskmash” JSC) by individual sectors. Its installation is scheduled for the end of the current year.

Two of six boilers designed for the power unit #1 are already delivered to the site. The weight of each is over 32 tons. The boilers will be used to supply heat to Novovoronezh; two heating mains, involved in the same scheme of heat power along with the boilers, will be laid from NPP‑2. A total of 12 boilers of delivery water are to be issued by the factories (“Power Machines” OJSC and “Sarenergomash” OJSC).

The installation of two steam generators is in progress at the moment. In November the specialists are about to start the assembly of the third and the forth. The work is to be completed by the end of the year. All steam generators are produced by “ZIO Podolsk Machine-Building Plant” JSC. The plant will also produce four steam generators for the second power unit. The operating life of the steam generators is 60 years, which is longer than of those of the previous generations.

The concreting of the fourth and the fifth tiers of the reactor building power unit #2 containment is in progress.

The construction of the cylindrical part of the reactor containment building is planned to be completed in December. Today the pre-assembly of the metallic parts of the containment dome of the power unit #2 continues at the site.

Leningrad NPP-2

Today the work is going on 111 sites. The number of construction workers is 2274 people. The launch of the first power unit is scheduled for 2014, the second will be launched a year later.

This year the builders of the holding company “Titan-2” have mounted a metal frame of the power unit #1 turbine foundation. The amount of 1430 cubic meters of concrete are laid. Besides, the specialists have completed foundation for capacitors in the second power unit. About two thousand tons of equipment was installed. One of the most complicated operations was assembling lower and upper units of the condenser group piping system, with the weight of each detail about 100 tons.

The installation of the main travelling crane with a lifting capacity of 440 tons is completed for the building of the first power turbine. The specialists installed two span beams with the total weight of 200 tons. The launch of the crane is scheduled for November. Besides the installation of 57 tons of cable steel constructions in the electric supplies building of the power unit #1 of Leningrad NPP-2 is completed. The assembly of ten internal containment cable facing blocks, the reinforcement of outer containments on the power unit #1 reactor building is also ready.

In early November the equipment for the power unit #1 pile assembly with the total weight of 622 tons and most of it being out-of-gauge cargo is expected. For delivery has been chosen the sea route through the Gulf of Finland. The general track of the reactor from Izhora plants to Sosnovy Bor will be more than 140 km. The rest (the cover of the block and the pit) will be delivered by road. Reactor equipment, including VVER-1200 reactor vessel, compensator and pipe protection unit for station under construction are produced on Izhora plants.

Beloyarsk NPP

The construction of the BN-800 power unit on Beloyarsk NPP is going on according to the schedule. Its launch is planned for 2014. It is planned to imbed in concrete the walls of the reactor pit at the Beloyarsk NPP site by the end of the year, as well as install a temporary shelter over the pit with purity and microclimate conditions required for assembling integrated units of the reactor vessel and make transportation of the first element of the reactor vessel.

Today the foundation plate concreting for turbine generator, which is to be located in turbine room of the main building of the power unit has been completed. One turbine generator will be installed on the new power unit. Power unit #4 of Beloyarsk NPP is to generate about 5,522 million kilowatt-hours of electricity and 595 Gcal of thermal energy annually. Given the periodic costs of time for refueling, maintenance and scheduled repair of equipment, new power capacity factor will amount to 80%.

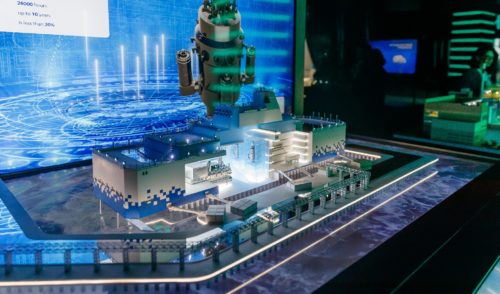

Floating NPP

USC and Rosatom these days are negotiating over further funding of the first floating nuclear power plant (FNPP) construction, which is being built at the Baltic Shipyard in St. Petersburg. As Andrew Dyachkov, the President of USC, reported in October, USC and “Rosenergoatom” had agreed on all key items on the floating nuclear power plant construction completion. Now the floating power unit “Academician Lomonosov”, designed for the major FNPP is currently under construction on the Baltic Shipyard. The readiness of the power unit is 65%.

In September the representatives of “Rosenergoatom” confirmed their plans to release a series of floating nuclear power plants, and in early November they intend to put an end to the contract negotiations with USC. Russia’s first floating nuclear power plant was to be constructed in Pevek of Chukotka and Kamchatka’s Vilyuchinsk. The launch of the station was initially planned for 2015-2016. At the public hearing in August 2010 based on “Environmental impact assessment of the construction and operation of floating NPP” the citizens of Pevek supported the construction of floating nuclear power plant and came out for its placement in Pevek.