AEM Offers Nuclear Desalination Solutions

back to contents– How challenging is water shortage today and how can it be eased with desalination of sea or ground water?

– As global population is growing and water resources are shrinking, demand for fresh water exceeds supply. According to the UN, demand is expected to grow threefold by 2030 to outrun supply by 40%. Water desalination and reuse will be key solutions to water shortage.

With nearly 30 cubic kilometers of seawater desalinated every year, this volume will reach 110 cubic kilometers by 2030.

I would like to mention that desalination is almost the only way to deal with fresh water shortage in many countries, particularly in the Middle East. Prosperous countries, such as United Arab Emirates or Saudi Arabia, operate numerous desalination plants, and their numbers are growing. A good example is Egypt and Iran that have been using ground water, and so has Crimea by the way. However, ground water becomes saline with time and needs desalination.

– Water desalination is power consuming. What power sources are used in the countries that extensively desalinate water?

– A desalination plant uses water steam and power. At present, 10–15% of desalination facilities globally are built in a combination with a thermal or another power station. This approach is reasonable as it saves capital costs and operating expenses.

We know that there are three basic resources in short supply – power, water and food. They all are interconnected as power is needed to produce water; water is needed to produce food, and so on. Power is also needed to process and store food products.

This is why some countries delegate power and water management functions to one ministry. By the way, Thirsty Energy, a special initiative launched by the World Bank, provides for an integrated management approach to all three basic resources. Apart from power supply and desalination, Thirsty Energy is generally centered on efficient use of water resources and addresses such issues as construction of hydropower plants on transboundary rivers.

– Is nuclear power used for desalination?

– The only example of integration between a nuclear station and a desalination facility is a desalination plant in Aktau (Kazakhstan). Commissioned in 1967, the plant produced enough fresh water for local industrial and civil facilities.

All the machinery was manufactured by Sverdlovsk Research Institute of Chemical Engineering, which is now a subsidiary of Rosatom’s nuclear engineering division AEM. The institute has been designing desalination plants by now.

The plant in Aktau had been in operation for nearly 40 years, more than its design service life, until MAEC-Kazatomprom began retrofitting it in the mid-2000s. Two tenders conducted by the company were won by IDE Technologies (Israel) and SIDEM (France). Israeli equipment is already in operation, while French machinery is in the process of commissioning.

It should be noted that after the nuclear reactor was decommissioned in 1999, the Aktau desalination plant has been powered by thermal stations built long before as backup capacities.

– What does AEM have to offer Kazakhstan?

– I would like to point out that nuclear is not the only field where our parent company Rosatom is active. Other fields of interest are medicine, wind power generation and many others, which are allied with the nuclear industry or totally unrelated to it. Half of AEM revenue comes from petrochemical, shipbuilding and other non-nuclear industries. Water desalination, or Clean Water, business has been launched as a promising area of future development. Many countries where Rosatom is building or plans to build nuclear stations are in need of fresh water. We think it reasonable to offer them the latest solutions in this field. As we grew interested in the new business, we took a look at years of our experience. Our desalination equipment in Kazakhstan has lasted for 40 years. We think that we can also tap to the unique experience of MAEC-Kazatomprom in operating the desalination plant.

With this in mind, two years ago we proposed MAEC to jointly develop desalination equipment for pilot testing in Aktau. If tests are a success, the same equipment can be installed on other sites in Kazakhstan and abroad.

MAEC provided us with basic specifications for performance, economic efficiency, technology and reliability, and we have developed a solution that can be used a basic design for a new desalination plant. We have retained all our R&D and engineering competencies. Although Russia has no water shortage, many nuclear and thermal power facilities use desalination equipment to produce make-up water for operation needs. Petrochemical plants need to comply with strict environmental requirements for water they discharge. This is where our systems can be used as well. Numerous production processes yield contaminated or saline water. Sverdlovsk Research Institute has recently won a contract with Russian oil major SIBUR although foreign companies also took part in the bidding process. Out activity in this field is not merely a theory or a desire to design new plants, but rather real projects we are implementing now and planning to do it in the future.

– Do your plants have advantages over foreign equipment?

– Specifications and performance of our plants are comparable with those of foreign counterparts, but we do not supply machinery and equipment – we offer participation in the design and production process. If our colleagues from Kazakhstan join us during the engineering design phase, this will be its first contribution to the project. In this case, some of intellectual property rights will belong to MAEC. Production of steel structures in Kazakhstan can be another contribution. It is surely more convenient and reasonable to make part of them in Kazakhstan than deliver them from Russia. Further on, machinery and equipment shipped to other customers or third countries will need maintenance, and operating staff will need training. This is the third opportunity for Kazakhstan to participate.

Cooperation with AEM was approved by Kazatomprom management and Kazakhstan’s Prime Minister. Some time has passed since then, and we would like to discuss the project with Kazakhstan partners once again.

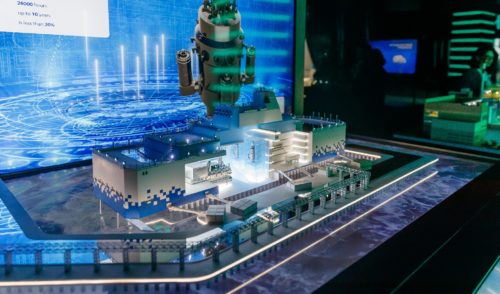

Since technologies we have are tried and tested, it can be completed within about two years. We propose to jointly develop distillation plants with a capacity of 300 cubic meters per hour or 12,600 c ubic meters per day. The plants can be installed anywhere if there is a source of steam – a thermal or nuclear power station – and a need of fresh water. Eight similar plants with an hourly capacity of 50 cubic meters each operate at all four reactor units of the Rostov nuclear station. Performance of desalination plants can be further improved after we analyze their operation over time in Russia and Kazakhstan.