Evolution of VVER Reactors

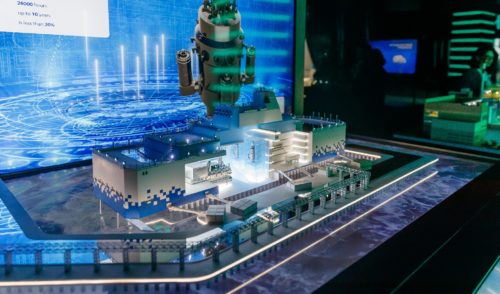

back to contentsVVER-TOI: a superpower station

Powerful: 1,255 MWe per unit

Strong: withstanding a 9 magnitude earthquake and a 400-ton airplane crash

Durable: 72-hour off-line operation

Long-living: 60-year service life

Fast: 40-month construction period

Flexible: output power maneuvering

Omnivorous: able to run on MOX fuel

The two-unit VVER-TOI nuclear station project has evolved from AES-2006, a design implemented in the Novovoronezh station under construction. Its major advantage is that most solutions it employs are time-proven and have been used in other nuclear stations built by Rosatom. Passive safety systems, for example, have been fully tested in operation at India’s Kudankulam. By the way, they have been further improved to incorporate post-Fukushima requirements.

Standardized

The letter T in its name stands for the Russian word meaning ‘standardized’. VVER-TOI design is quickly adaptable to any climatic or seismic conditions and requires no major modifications. This means that the VVER-TOI station can be built either in moderate or harsh environments and is not vulnerable to hurricanes, tornadoes, floods or earthquakes. “Our engineers had never given a thought to anything more serious than an 8 magnitude earthquake. After Rosatom came to earthquake-prone countries, such as Turkey, Bangladesh, Jordan or Vietnam, the design was modified to account for earthquakes up to magnitude 9,” says Andrei Kuchumov.

Standardization makes the construction process simpler and faster. "The standardized design saves several months of construction – not from the first project, of course," Kuchumov explains. "We estimate that construction of the first reactor will take 48 months. Other reactors will be built in just 40 months."

Optimized

The letter O in the name stands for ‘optimized’. According to estimates, VVER-TOI construction and operation costs will be respectively 13% and 10% lower as compared to Novovoronezh Unit 6 (under construction) and Balakovo Unit 4 (already in operation). The first changes were made to the master plan. As the layout of facilities was modified, the site area decreased 30%, resulting in less concrete and shorter pipes and cables required for the construction. In the reactor island, the most important modification was a parallel arrangement of steam generators. Changes in the design also resulted in optimized maintenance and repair procedures.

Information technologies

Finally, the letter I stands for ‘information’. The VVER-TOI project employs a variety of IT solutions that create a continuous information environment spanning from design and construction to operation and decommissioning of the nuclear station. The single information environment will reduce costs at every project stage and make the entire project more affordable.

Approved for construction

VVER-TOI is more competitive than other Generation III and III+ designs, and its specifications meet all international standards and requirements. Early next year AtomEnergoProekt will draft tender documents for Rosatom to bid for the next international tender with its VVER-TOI design

In Russia, the VVER-TOI project is implemented at Kursk-2. The first unit to be commissioned in 2023 will become a flagship reactor of this design. Rosatom expects to obtain a construction license for Akkuyu (Turkey) in March 2018.

Fast construction

VVER-TOI will set a new record for the price and time of construction. New solutions are a way to optimize and speed up the nuclear construction process. The design provides for the use of advanced construction materials, self-compacting concretes, reinforcing frames and permanent formworks.

Since quality of installation is critical, the focus is on robotic welding. At Kursk-2, it will be the first time that piles will be used to fix loose ground. Open top installation of the core reactor components will significantly accelerate the construction process.

The next stage of design evolution will be the so-called LEGO technology, installation of pre-assembled modules with components mounted on them. Its advantage is that part of the work is done by the manufacturer at its premises where the quality of assembly is higher and installation is faster.