As Natural As Water

back to contentsIn this issue, we tell you about a new small nuclear power plant with a VVER-I reactor. Designed at OKB Gidropress, it is an integral modular reactor with natural coolant circulation.

Distinctive internals

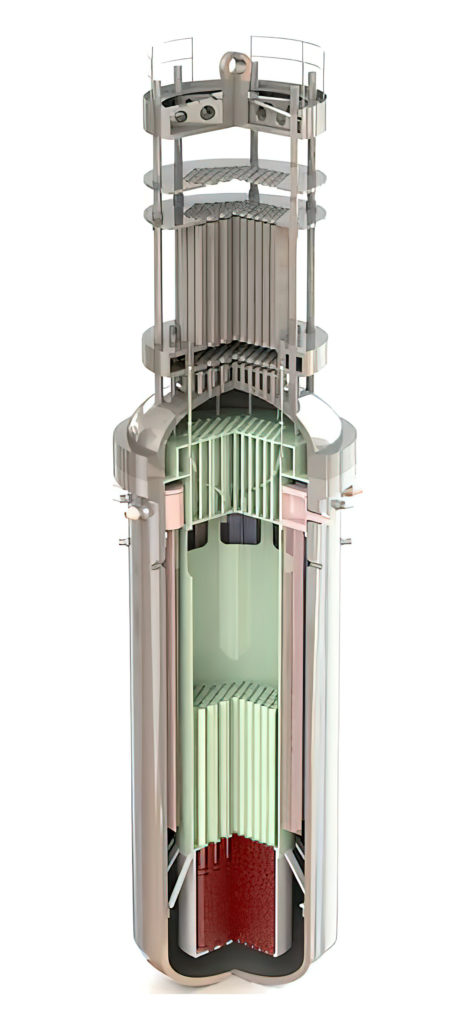

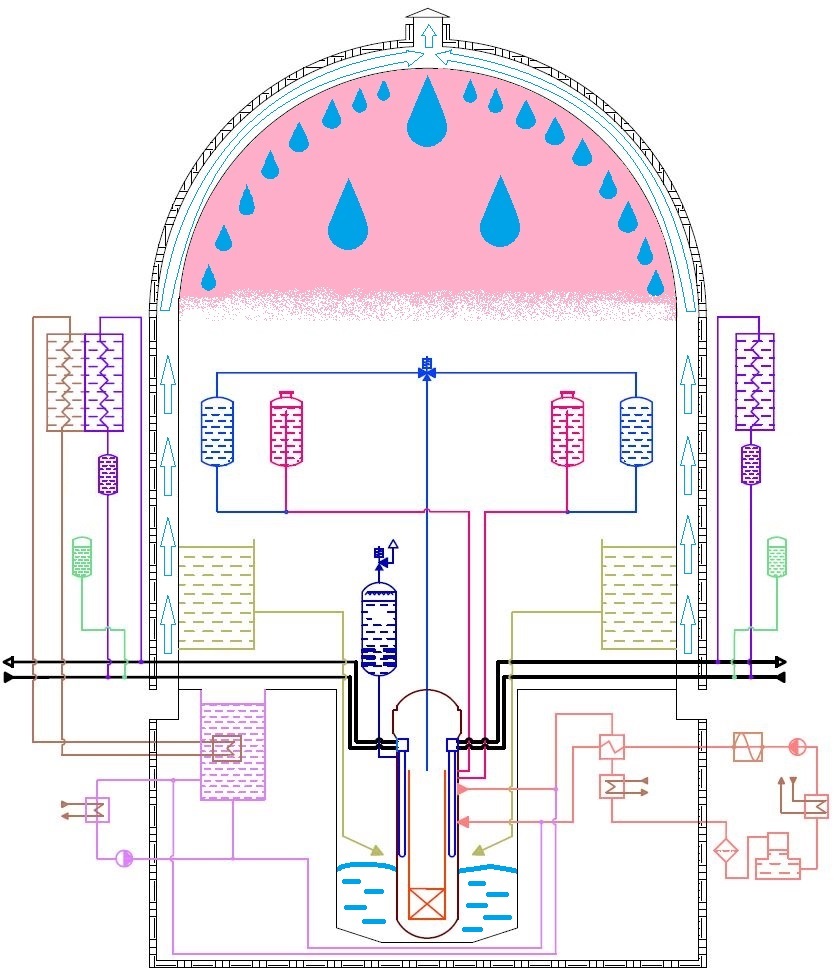

The VVER-I reactor pressure vessel (RPV) houses a core, a riser tube unit, steam generation modules, and other necessary internals. Water, which serves as a coolant, circulates inside the RPV only. Having a higher temperature and a lower density, it goes from the reactor core into the shell side of the steam generators, gets cooled there and returns into the core through the downcomer tubes. Location of the steam generators and the reactor core at different heights ensures natural circulation. Overheated steam with the pressure of 3 MPa and temperature of around 290°С goes from the steam generators into the turbine, circulating through heat exchangers. The primary coolant loop is therefore integrated into the reactor pressure vessel. The reactor in its basic version is capable of generating 250 MW of thermal power. Estimates show, however, that its thermal output can be increased to 400 MW without material changes in the design by simply raising the height of the RPV and steam generation modules by 1.5–2 meters. This will help to easily meet customers’ requirements.

Advantages of integral layout

The reactor’s integral layout reduces the inventory of equipment needed and size of the nuclear island. It also makes large-diameter pipes unnecessary. The largest high-pressure coolant pipe in VVER-I has a diameter of less than 100 mm. As a result, fewer safety systems are needed and all of them can be passive, which is another indisputable advantage of the new reactor. Its design does not provide for any active, human-triggered safety systems.

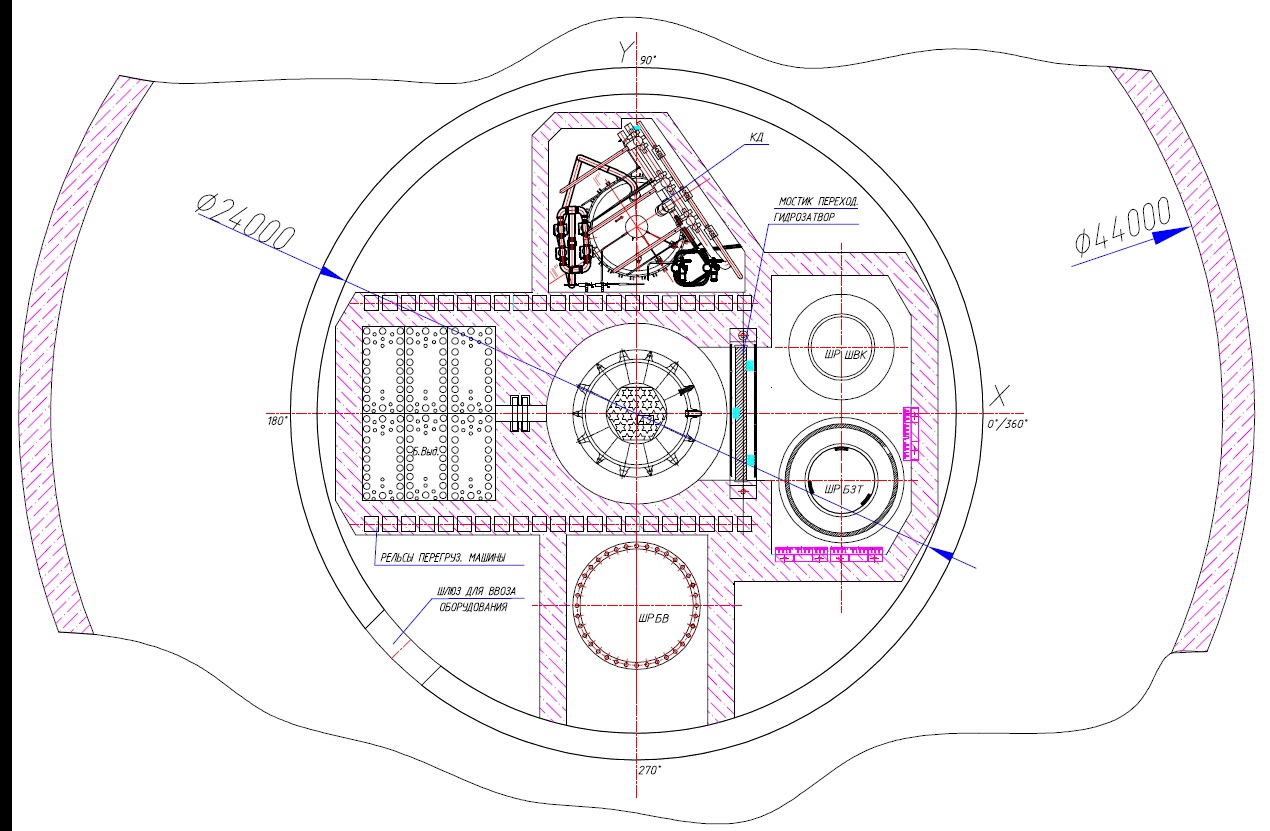

The principle of modularity applies to the entire reactor. The RPV houses seven modular steam generators that are easy to maintain, repair and even replace when needed. The reactor itself is also modular, which allows placing two or three reactors in a single containment.

Advantages of natural circulation

When in a natural circulation mode, more powerful VVER reactors are capable of producing more than 10% of their nominal power, or around 300 MW of thermal power. This has been confirmed by tests. Having taken this into account, engineers plan to achieve more power with the same RPV by reducing hydraulic resistance in the circulation loop and creating other conditions for continuous natural circulation. Correctness of this solution has been confirmed by Computational Fluid Dynamic (CFD) modeling. “In fact, there is no need to invent how circulation pumps can be integrated into the RPV, and so there is no need to feed or maintain them. In my opinion, the less complex equipment is and the simpler design, the more reliable it is,” says Mikhail Bykov, Head of Thermal Physics Department at OKB Gidropress (part of Rosatom).

Proven approach

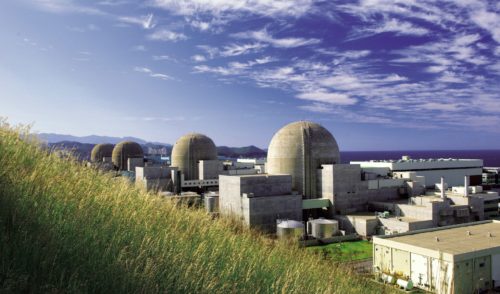

Many reactor design proposals were considered and analyzed at OKB Gidropress during the engineering process. In the end, engineers settled on time-tested technologies but still had to find many new solutions. “The RPV is similar to that of VVER-1000 reactors which have been in operation for over 1,000 reactor-years. We had to fit the steam generators and the core into it and faced a dilemma: should the coolant flush the steam generator tube or, on the contrary, should the secondary loop be arranged in the shell side? How to make a riser tube unit to ensure continuous natural circulation? We faced such dilemmas and problems now and then. And it was great that young people were involved in our work from the very beginning,” Mikhail Bykov says.

Young professionals proposed bold ideas, analyzed the options, and chose the best solutions. More experienced colleagues were guiding them and prompting the way. The technical proposal for a VVER-I reactor was finally elaborated even more than this development stage requires. Based on that document, the team prepared terms of reference for the VVER-I draft design, which will be the next stage of the reactor development process.

The draft design will be developed in close collaboration with the chief designer and the R&D supervisor to obtain the concept of the entire nuclear power plant and the scope of equipment and systems needed. “I believe that together we are capable of developing a VVER-I-based small nuclear power plant that will be cost effective, attractive to international customers and compliant with all applicable safety requirements to further strengthen Rosatom’s leadership in this market segment,” Mikhail Bykov concluded.

OKB Gidropress

provides comprehensive services in design engineering, computation, experimental testing, research and development of nuclear reactors for various-type power plants. The company also provides engineering supervision services throughout the service life of the equipment designed.