BREST Gets Based

back to contentsInstallation works have begun at the world’s first lead-cooled fast neutron reactor. Its safety will be ensured through the action of natural laws and inherent properties of structural materials. Reactors with such safety performance are classified as Generation IV.

Closing the fuel cycle

BREST-OD‑300 (Russian acronym for a ‘300 MW passively safe lead-cooled fast reactor for pilot demonstration purposes’) is part of a pilot power production facility (abbreviated ODEK in Russian) under construction in Seversk, Tomsk Region, in the premises of the Siberian Chemical Plant. ODEK will also include a spent fuel processing unit and a fuel fabrication and refabrication unit. They will produce fuel assemblies for BREST, which will use mixed uranium-plutonium nitride (MUPN) fuel made from depleted uranium and reactor-grade plutonium by carbothermal synthesis.

ODEK is the first embodiment of the Proryv (‘Breakthrough’) Project aimed at changing the nuclear generation paradigm by closing the nuclear fuel cycle with fast neutron reactors. The project provides for the development of integrated nuclear power facilities that will consist of a nuclear power plant and fuel reprocessing (spent fuel conversion into fresh fuel) units.

Such facilities will be designed in a way that excludes the possibility of accidents requiring evacuation of local residents. The nuclear power plants should be competitive with other types of generation. The use of depleted uranium and irradiated nuclear materials for the production of fresh fuel will make it possible to close the nuclear fuel cycle. This concept will maximize the use of energy contained in natural uranium and reduce radioactive waste. Improved safety and lower waste will make nuclear power even more eco-friendly, cost-efficient and socially acceptable.

News from the site

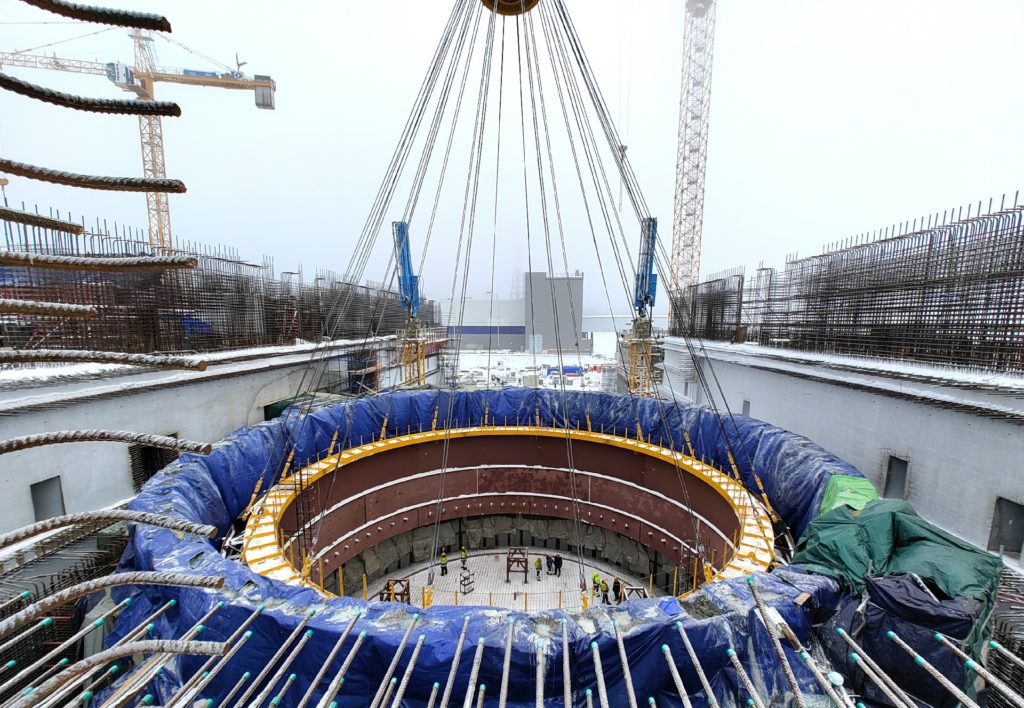

This January, a steel baseplate was installed to evenly distribute the loads from the reactor components on the concrete structures at the RPV bottom. The two halves of the plate were delivered from Saint Petersburg and joined at the construction site.

This was followed by sinking the lower tier of the RPV protective structure into the reactor pit. It will hold heat-insulating concrete and serve as an additional protective barrier outside the coolant circuit. The surface temperature of the structure must not exceed 60 °C and the background radiation must not exceed the natural level.

“Unlike conventional light-water thermal reactors of the VVER family, the BREST fast reactor has an integrated layout. Its pressure vessel is not an all-metal structure as VVERs have, but a concrete and steel structure with steel cavities to accommodate primary circuit components. The space between the cavities is filled with concrete step by step during the construction process,” explains Vadim Lemekhov, Chief Designer of the Proryv Project.

And more…

Almost all the components of the reactor unit are either being, or about to be, manufactured. Some of the reactor control and protection systems have already been produced. The pilot modification of the main circulation pump has been tested to demonstrate it is capable of pumping over 11 tonnes of molten lead per second, although there were doubts about the possibility of achieving this performance measure. Russian nuclear engineers have also developed new and more effective codes to replace foreign codes used earlier.

Rosatom is conducting an extensive fuel testing program, with fuel rods irradiated and then undergoing post-irradiation studies. Much work is underway to substantiate the use of MUPN fuel and increase its burnup. Meanwhile, the MUPN production technology is being finalized at the fuel fabrication and refabrication unit.

Plutonium dioxide bred in the 1970–1990s and stored at the Mayak site will be used to make this fuel. Its stockpile is sufficient for the first load and some subsequent reloads. Fuel irradiated at BREST will be used to produce new MUPN batches after that.

Recruitment of BREST personnel has begun, with two training simulators already in place. A full-scale simulator will be built later.

Future planned

“This year, we plan to complete tests on the pilot main circulation pump and obtain a production permit for the pumps to be installed at the reactor unit,” Evgeny Adamov, Science Director of the Proryv Project, told the nuclear industry newspaper Strana Rosatom. Also in 2024, pre-commissioning operations are going to be completed at the fuel fabrication and refabrication unit. Production of the first fuel core will begin next January.

BREST is scheduled to go critical in late 2026. As Vadim Lemekhov told Atominfo.ru, preparations for the first criticality are expected to take four months.

Although the work at the ODEK is in full swing and there is still much to be done, development of a commercial fast neutron reactor BR‑1200 is underway. “The calculations made and experiments conducted as part of the feasibility studies are basically sufficient to make high-probability predictions for the BR‑1200 design,” Vadim Lemekhov says with confidence. It is quite possible that a nuclear power plant with a BR‑1200 reactor will be built in the Southern Urals before 2045.