Light Steps of Composite Materials

back to contentsProduction of composites is one of Rosatom’s most interesting new businesses. These materials are used, among other things, in advanced vehicles, clean energy generation, cost-effective construction solutions, and high-performance sports.

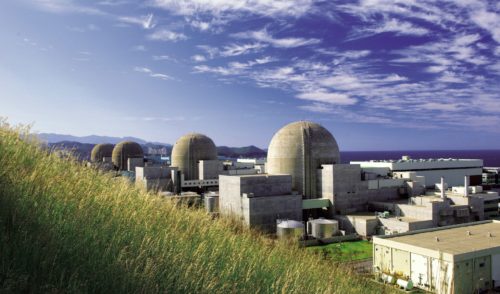

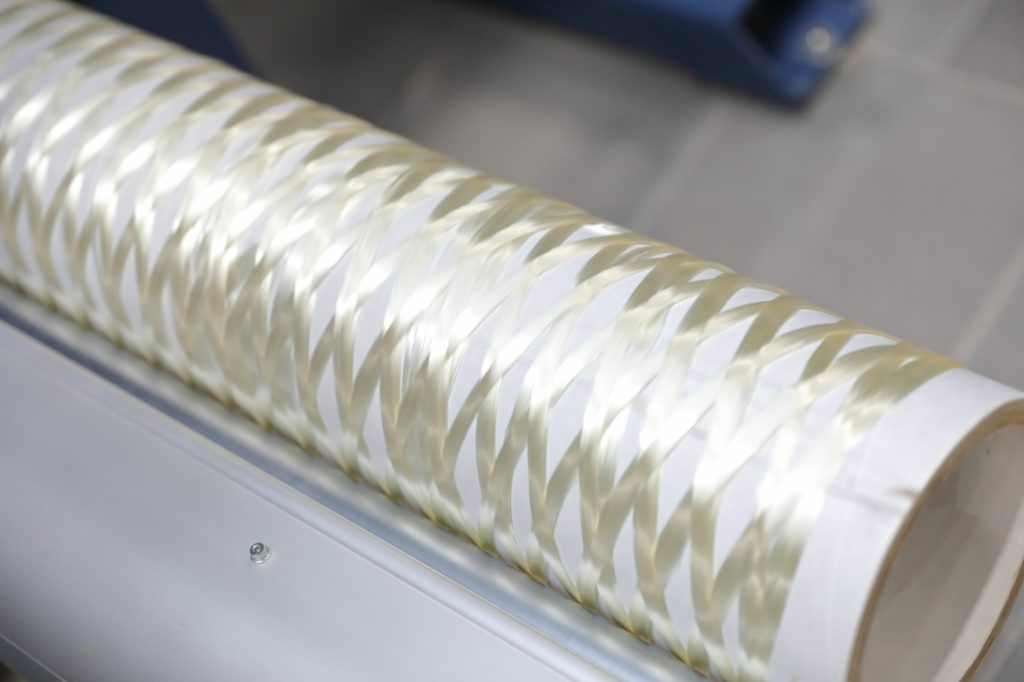

Back in the 1970s, the USSR belonged to the top three producers and consumers of composite materials in the world. They were, and still are, used to manufacture gas centrifuges for uranium enrichment. Since 2016, Rosatom has been making consistent efforts to set up an end-to-end composites production chain — the only one in Russia, CIS countries and Eastern Europe — that spans from crude oil processing to finished products like ship hulls, car bodies, fuel gas cylinders, construction materials, and sports equipment. Rosatom Group companies also produce PAN precursors, a variety of carbon fibers, fabrics, tapes, and prepregs.

The Russian composites market is still small in absolute terms, making as little as about 1 % of the world market, but it is growing at the global rate of around 5–6 % per year. On the upside, the Russian market of carbon composites, in which Rosatom is a leader, showed a 3.5 fold growth over the past six years alone.

It will continue to rise, particularly on the back of demand from the aircraft industry, which uses composites for the production of aircraft parts. Demand from the shipbuilding sector is also expected to increase. In September 2022, Rosatom signed an agreement to construct a shipyard in the Far East. The shipyard is assumed to build fully composite small-sized fishing, passenger and cargo ships.

Rosatom also intends to manufacture proprietary designed blades for wind turbines. They will be made of 90 % glass fiber, with the remaining 10 % being carbon fiber stiffeners. The first set of blades will be ready by the end of this year. The plan is to supply the blades to both national and international markets as the work is underway to develop several wind power projects overseas.

Rosatom holds a leading position in the Russian market of composite gas cylinders for buses, trucks, gas transportation and storage systems, and mobile refueling stations. Export orders are also in the pipeline. For example, the first shipment of 1,500 gas cylinders was delivered to the Minsk Automobile Plant (MAZ) last year. The next stage is to finalize the design of hydrogen cylinders; their prototypes have been made and are being tested. Aiming at the production of hydrogen and equipment for hydrogen economy, the Russian nuclear corporation is developing a line of small and large capacity tanks for different applications, from cars and trucks to gas carriers. Rosatom is also developing composite body parts for Russian electric vehicles.

Composite materials are becoming increasingly popular with the construction and infrastructure sectors both in Russia and other countries. Rosatom has upscaled its product offering for these sectors over the past 3–4 years.

Rosatom subsidiaries produce and supply composite sheet piles and chutes for coastal reinforcement structures and external reinforcement systems for the upgrade and capital repair of buildings and structures, make engineering plans of one-piece composite pedestrian bridges, and build coastal sites for commercial and household needs. External reinforcement systems allow structures like bridges to be repaired without suspending their operation. This might be critical for the cities divided by a river — such locations are in plenty all over the world. Composite sheet piling is used to isolate hazardous facilities. Sinking sheet piles into the ground prevents mercury, petroleum products and other pollutants from getting into groundwaters.

Consumption of composite materials in sports is also growing. Professional hockey sticks were Rosatom’s first composite product for the sports sector, which was only the beginning. Not long ago, a novelty product — professional SUP boards — hit the market. Leading Russian athletes rated it high.

Prospects

Rosatom puts much effort into pushing its composite materials business forward across multiple dimensions, and the first of them is expansion of the product range for the sectors discussed above. Second, the company is building new production capacity. Third, it is engaged in the development of proprietary equipment for the composite materials sector. The fourth is the production of chemical agents for composite binders. The fifth is the development of new technology and solutions, and the sixth is recycling.

Thus, Rosatom intends to install carbon and glass fiber production lines, partly using Russian-made equipment, and to increase the production of high modulus carbon fiber. Last year, Rosatom obtained the first samples of such fiber with a strength of 7 GPa. This ground-breaking product is a result of advanced research, with only two Japanese companies producing fiber of the same strength in the world so far. This fiber makes it possible to build even more light-weight structures, which is critical, for example, for space flights as placing each kilogram of payload into orbit costs a lot of money.

The recycling business is also going forward. Rosatom has installed the first line for chopping fabric leftovers. The chopped fabric is used as feedstock for stamping operations. This is the first step on the way towards composite waste recycling. Rosatom will continue working to make its composite materials more eco-friendly.

Rosatom also intends to build partnerships with international and local consumers to enter new markets with its high-tech composite products.

Global Composites Market 2023

Size: USD 100 billion

Glass fiber production: 12 million tonnes

Carbon fiber production: 120 thousand tonnes