BN-600: 45 Years of Fast Reactor Excellence

back to contentsThis year marks the 45th anniversary of Beloyarsk NPP Unit 3 with a BN-600 sodium-cooled fast neutron reactor. Its significance for the industry remains unmatched because it served as the proving ground for engineering solutions that today make Rosatom a global leader in liquid metal cooled reactor technology. BN-600 continues testing advanced fuel designs for next-generation reactors while demonstrating remarkable longevity: in late March, Russian regulator Rostechnadzor issued a 15-year extension license authorizing operation through 2040.

Historical context

BN-600 was not Russia’s first sodium-cooled nuclear reactor. It was preceded by the research reactor BR-5 (5 MW), which was later upgraded to BR-10 (10 MW), the still-operational BOR-60 (60 MW), and the power-generating BN-350 (connected to the grid in November 1972 and shut down in 1999). The BN-600 reactor became a bridge between Soviet-era developments and present-day liquid-metal reactor technology, proving the viability of this design for commercial applications of nuclear energy.

The development of BN-600 began after a landmark report made by one of Russian nuclear pioneers, Alexander Leipunsky, at a conference in November 1962. He proposed to increase coolant temperatures and thermal output by 50% (from 1,000 to 1,500 MW) to achieve a 600 MW electrical output. The idea gained approval and was incorporated into the USSR’s nuclear development strategy through 1980.

Innovative design

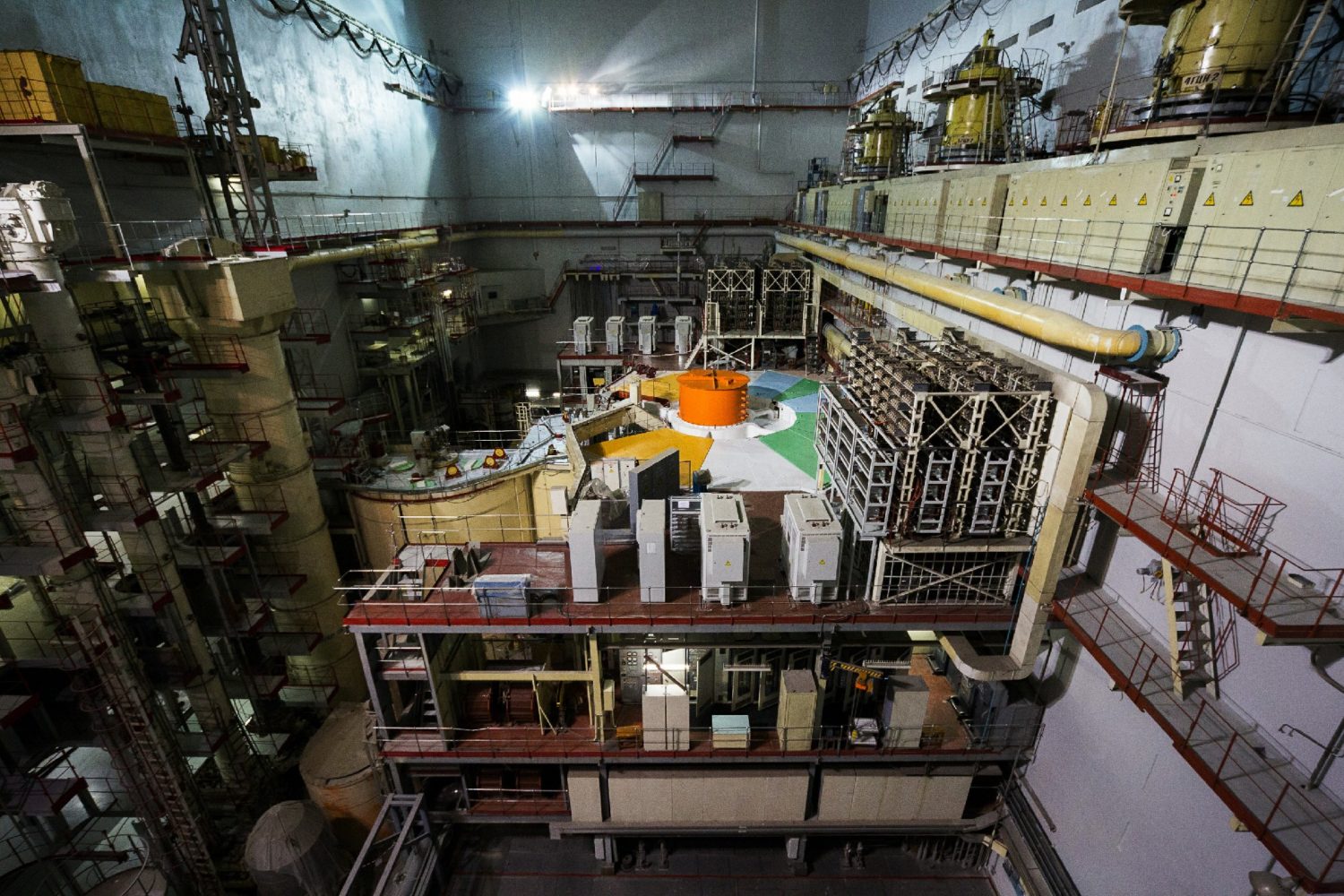

Designers used an integrated pool-type configuration, housing pumps and intermediate heat exchangers inside the reactor pressure vessel. Novel steel alloys were developed for the steam generators. Protected by a containment shell, the 12.5-meter-high reactor vessel sits within a 15‑meter-diameter concrete shaft.

The reactor core is surrounded by a radial breeding blanket of depleted uranium dioxide assemblies. Behind it is an internal repository with 126 cells for the assemblies taken out from the core. This is where they are cooled before being removed from the reactor.

The coolant system has three circuits. The primary and secondary circuits contain molten sodium, while the tertiary circuit contains water. Using sodium as a coolant necessitates specialized electromagnetic pumps, sodium purification filters, electric equipment and piping heating systems, water-to-sodium leak detectors, sodium/water reaction product isolation in case of loose joints in steam generator circuits, equipment for sodium fire suppression and sodium removal from fuel assemblies, and other systems.

Proving ground for future reactors

Construction of the BN-600 power unit began in 1968, with grid connection achieved in April 1980. After addressing first-of-a-kind issues (fuel rod leaks, weld failures, pump malfunctions, and so on), which are typical of any new reactor designs, BN-600 reached full power in December 1981.

Continuous upgrades have marked the BN-600’s operational history. In the late 1980s, the core was redesigned to have three (rather than two as before) enrichment zones. In 1991-1993, new radiation-resistant structural materials were introduced for the fuel assemblies, increasing fuel burnup from 7% to 11.3% of heavy atoms. Thanks to later improvements, the current fuel burnup is 11.8%.

BN-600 runs on oxide fuel, but the reactor is also used to carry out tests on multiple experimental assemblies, primarily with mixed uranium-plutonium oxide (MOX) fuel in the form of pellets or vibro-compacted rods. Those tests helped to validate the safe use of MOX fuel in BN-800, now the world’s only fast neutron reactor operating entirely on MOX fuel. Currently, BN-800 is testing mixed uranium-plutonium nitride (MUPN) fuel destined for the lead-cooled BREST-OD-300 reactor under Rosatom’s Proryv (Russian for ‘breakthrough’) closed fuel cycle initiative.

Long operating life

The original 30-year design life of Beloyarsk Unit 3 with the BN-600 reactor expired in April 2010. Since a decision was made in advance to extend its service life, the power unit underwent extensive refurbishment, with steam generators and valves replaced, a steam turbine and a circulation pump overhauled, and some systems upgraded. Following the refurbishment, the regulator issued a 10-year service extension license until March 31, 2020. On April 1, 2020, the Beloyarsk NPP obtained another extension license for 5 years.

On March 31, 2024, in the year of the 80th anniversary of Russia’s nuclear industry, the Russian nuclear supervision authority Rostechnadzor granted a new 15‑year license. Safety of the extended operation was confirmed by comprehensive safety reviews by the regulator.

“Unit 3 of the Beloyarsk NPP remains the cornerstone of future nuclear technology. It pioneered industrial-scale tests on the first MOX fuel assemblies made from irradiated nuclear fuel, and now its core contains assemblies that will validate the quality and safety of fuel and materials for fourth-generation reactor designs like BN-1200M and BREST. Even more valuable are the operational insights our team has gained from decades of fast neutron reactor experience,” Beloyarsk NPP Director Ivan Sidorov pointed out.

Photo by: Rosenergoatom Concern JSC