Storage Batteries at Industrial Scale

back to contentsIn late 2025, the Russian nuclear corporation launched the country’s first large-scale production facility for lithium-ion batteries. This new factory has dramatically expanded Rosatom’s capabilities to drive electric mobility both in Russia and internationally.

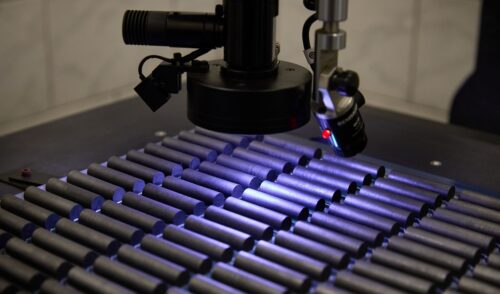

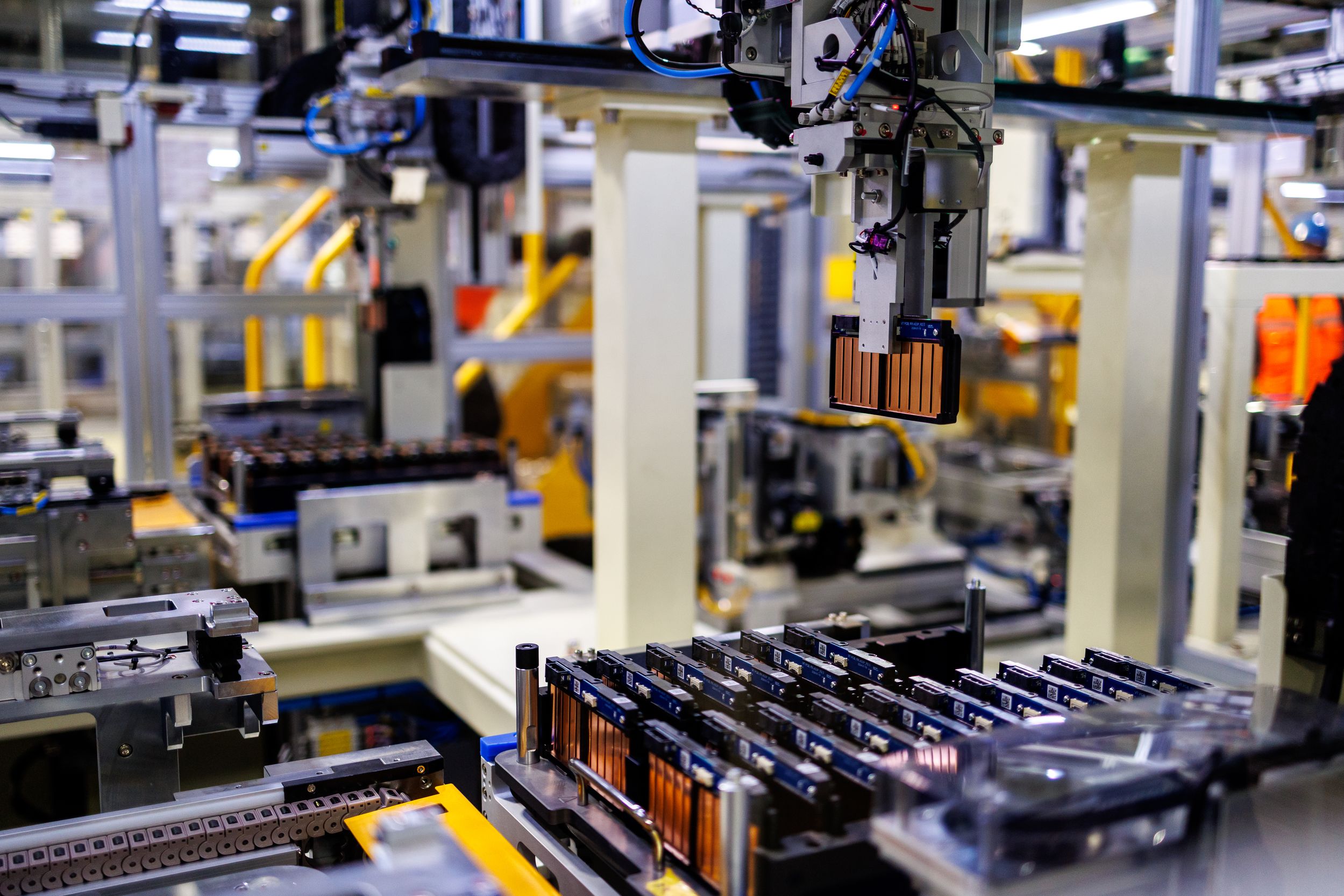

Rosatom’s gigafactory, which commenced operations in the Kaliningrad Region in December, is a vertically integrated production facility. The production cycle encompasses slurry preparation, coating the active material onto metal foil to create an electrode web, and precision slitting and notching into specific shapes. The electrodes are then assembled into pouch cells, filled with electrolyte, and integrated into battery modules. The final stage involves full battery pack assembly, including the integration of advanced thermal management and battery management systems With nearly 90% of processes automated, the factory achieves a high-speed output of one cell per second.

Background

After evaluating 30 potential sites for the gigafactory, Rosatom selected the Kaliningrad Region for its preferential business environment. The construction agreement was signed in September 2021. On-site work began in October 2022; installation of utilities started in summer 2025, followed by production lines in the autumn.

The factory is currently in the pilot operation phase, during which its manufacturing systems and equipment are being fine-tuned. The facility is scheduled for full commercial commissioning in 2026. Another such gigafactory is being constructed by Rosatom in Moscow.

For Russia…

“The launch of the Kaliningrad gigafactory is an industrial breakthrough for Russia and a major contribution to the foundation of national technological sovereignty. Energy storage is a cross-cutting technology in Rosatom’s portfolio of new non-nuclear businesses, enabling the deployment of end-to-end production chains and product ecosystems,” said Rosatom Director General Alexey Likhachev at the launch ceremony. “This includes the lithium product chain — from mining raw materials to recycling spent batteries — and industrial cooperation in the new Electric Mobility business area.”

The emergence of Russia’s first large-scale domestic battery manufacturer will make Russian electric vehicle production more resilient by eliminating the risks associated with imports. Furthermore, in-house production allows for continuous technology improvement and innovation, such as testing new cathode and anode materials and electrolytes developed by Russian scientists and engineers.

…and for international partners

The launch of the gigafactory also enhances Rosatom’s potential for cooperation with international partners. One of the closest collaborations in the energy storage segment is with Belarus. During the World Atomic Week held in September 2025, Rosatom signed a roadmap for cooperation on traction batteries with the Belarusian manufacturer of urban electric ground transport, BKM Holding (also known as Belkommunmash). The roadmap outlines plans for supplying Rosatom’s lithium-ion batteries for BKM Holding’s electric buses and for organizing a local factory for traction battery assembly in Belarus.

This roadmap builds upon the existing cooperation. In 2022, Rosatom supplied lithium-ion batteries for 97 trolleybuses manufactured by BKM Holding, which are now in passenger service in St. Petersburg.

4 GWh per year

is the gigafactory’s production capacity (equivalent to manufacturing 50,000 EV traction batteries)

A holistic approach

Rosatom is developing electric mobility in Russia in a consistent, holistic manner. The Russian nuclear corporation manufactures electric vehicle charging stations (EVCS) and operates an EVCS network. Notably, this network is powered by carbon-free electricity generated by Russian nuclear power plants, which is certified by green certificates. Users of the Rosatom charging network can be confident that the electricity powering their vehicles is carbon-free “from generator to charging plug.” Additionally, Rosatom is working on a project to build a plant in the Lipetsk Region for manufacturing traction electric drives, comprising an electric motor, gearbox, and inverter. Finally, Rosatom supports scientific research in battery chemistry and the development of new battery technologies.

Photo by: TVEL JSC (Fuel Company)