From Russia to Bangladesh with Love

back to contentsHigh officials from Bangladesh visited the Petrozavodsk branch of AEM Technologies (part of Rosatom’s engineering division Atomenergomash). The delegation was headed by Kamrul Ahsan, Ambassador of Bangladesh to Russia. Other delegates included Subhashish Sardar, Counselor for Nuclear Energy at the Embassy of Bangladesh in Russia and a group of experts from ASE Engineering Company (Rosatom’s engineering division) headed by the company’s Deputy Director for Local Equipment and Materials Sergei Streltsov and Deputy Director for Equipment Supply Project Sergei Osipenko.

Pavel Marchenko, Director of Petrozavodskmash, told the guests about the company’s history, current operations and progress in the production of equipment for the Rooppur nuclear power plant. While taking a tour of the production facility, the visitors learned about nuclear machinery production practices and were shown how nuclear equipment, including that for the Rooppur NPP, was manufactured.

“The goal of our visit is to view the process of making the equipment for our nuclear power plant. What we see here is sophisticated high-precision machinery in action, so we have no worries about the quality and safety of products manufactured here,” Bangladesh Ambassador Kamrul Ahsan said.

“As the general contractor, we appreciate the confidence of our customers from Bangladesh. Customer visits to the manufacturing plants help us demonstrate that all the equipment for the Rooppur NPP is made to high quality standards and right on time,” Sergei Osipenko stressed.

Pavel Marchenko noted that fulfilling the order from Bangladesh was both an honor and a great responsibility. “Today, we have had an opportunity to show our guests not only the process of manufacturing nuclear equipment, but also products for the Rooppur NPP at the final stages of production. Petrozavodskmash is already shipping the first items of this order,” the plant director said.

The first product shipped was a main circulation pump casing — a safety class 1 product — made at Petrozavodskmash. At a nuclear power plant, the main circulation pump ensures that the coolant flows from the reactor to steam generators. The pump operates under the pressure of about 160 atm and temperature of 300 °C. Each reactor unit needs four spherical casings for the main circulation pumps.

A single spherical casing weighs more than 31 metric tons, measuring 3.5 m in height and over 3 m in width. The finished products are transported by road to the sea port of St. Petersburg to be transshipped and delivered by sea to the port of Mongla, Bangladesh. Upon arrival, they will be loaded onto a riverboat and transported by the Padma River to the pier near the Rooppur construction site.

The production of equipment for Rooppur is also underway at other subsidiaries of Atomenergomash. ZiO-Podolsk has produced and shipped a set of turbine island equipment for Unit 2 of the would-be nuclear power plant. Rooppur will receive the first of three sets of separators and superheaters. They are intended to dry and superheat wet steam coming from the high pressure cylinder of the turbine. Their service life is 50 years.

The company has also shipped two accumulation tanks of the emergency core cooling system (ECCS) and two high-pressure preheaters for Unit 2.

The ECCS tanks are designed to supply a cooling boric acid solution into the reactor core in accidents involving coolant leaks from the primary circuit (loss-of-coolant accidents). High-pressure preheaters belong to the turbine island equipment and are intended for feedwater heating. The total weight of the products shipped approximates 400 tons.

Atommash, the Volgodonsk-based branch of AEM Technologies, has finished the assembly of steam generators for Rooppur Unit 2.

It took 21 days to mount 11,000 coiled tubes row by row (105 horizontal rows in total) inside each steam generator. The coiled tubing is made from straight tubes, each 10 to 16 meters in length, and placed inside the steam generator, with the tube ends connected to the primary circuit collectors. Afterwards, welders flare and weld the tubing ends.

Steam generators belong to the nuclear island and are safety class 1 products. The next step is to weld the top and bottom plates to the generator vessels. The steam generators will undergo hydraulic tests and a series of quality control procedures, including eddy current tests of the heat exchange tubing.

In mid-October, the reactor vessel and steam generators for Rooppur Unit 1 arrived at the construction site. A special barge carrying the core equipment moored at the newly built river pier. The cargo had been delivered from the port of Mongla under military escort. “The people will have more confidence in the equipment as it has traveled such a long way, nearly 15,000 kilometers from the famous Russian river Volga to the famous Bangladeshi river Padma,” Yafes Osman, Minister of Science and Technology of Bangladesh said.

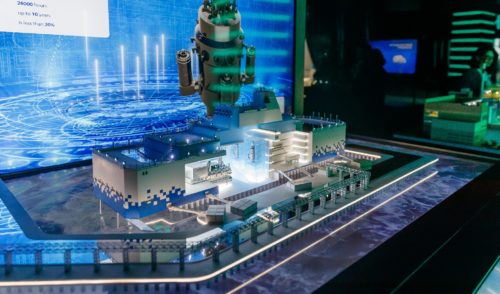

Featuring two Russian-designed VVER‑1200 reactors with a total power capacity of 2,400 MW, the Rooppur NPP is constructed 160 km away from Bangladesh’s capital Dhaka. The country’s first nuclear power plant will be based on the Russian design featuring VVER‑1200 reactors. Their service life is 60 years and can be extended by another 20 years. Rooppur Unit 1 is scheduled for commissioning in 2023 followed by the second unit in 2024