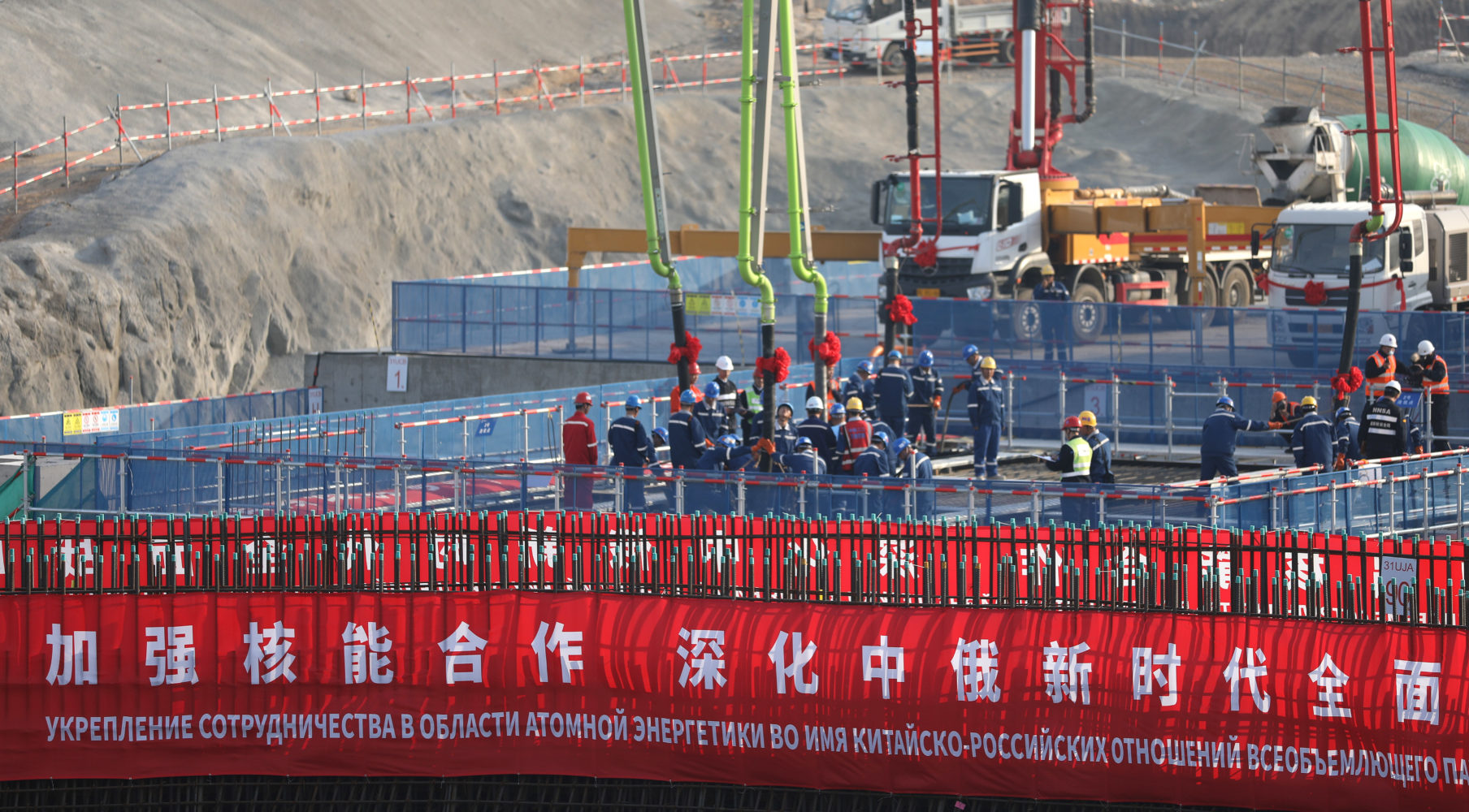

First Concrete for Xudabao

back to contentsThe first concrete pouring ceremony was held at Xudabao (also known as Xudapu) Unit 4 NPP built to the Russian VVER‑1200 design to mark the beginning of an active construction stage. You will learn more about Rosatom’s construction sites in China from this article.

The first concrete was poured for the foundation of Unit 4 on May 19.

“Construction of two latest Generation III+ reactor units at Xudabao goes on schedule and even ahead of it. The Russian party meets its obligations in full as a team of supervising engineers is working on the site while equipment and construction documents continue to arrive in compliance with the contract,” says Alexei Bannik, ASE Vice President for Chinese Projects.

Simultaneously, construction works are underway at the site of Unit 3: the reactor building will reach the height of +8.00 meters by the middle of the year. Rosatom also builds two reactors for the Tianwan nuclear power plant. The Chinese party expects Tianwan Unit 7 to be put in operation in 2026, followed by Tianwan Unit 8 and Xudabao Unit 3 in 2027 and Xudabao Unit 4 in 2028.

A strategic package of agreements defining key areas of cooperation between Russia and China in the nuclear industry was signed in Beijing in June 2018. The signing ceremony was attended by the heads of the two states. In 2019, the parties signed several contracts, including a general contract for the construction of Xudabao Units 3 and 4 and a contract for the supply of nuclear fuel for these two reactors.

As set out in the contracts, Rosatom produces a design of the nuclear islands and supplies key equipment and machinery for the two units at Tianwan. At Xudabao, the Russian nuclear corporation will deliver the same scope of work and also provide design supervision, installation and commissioning services.

Russian nuclear companies continue to manufacture core machinery and equipment for Xudabao. In late May, Atommash, a Volgodonsk-based production facility of Rosatom’s power engineering division AtomEnergoMash, manufactured a set of bends for the primary coolant pipes of Unit 3. The set consists of 12 pipe bends, each weighing 7 tons.

The primary coolant pipes connect all the systems and equipment that belong to the primary loop, including the reactor, steam generators and main circulation pumps. It carries water at the temperature of 320 °C and pressure of 17.6 MPa that acts as a coolant. The primary coolant piping belongs to Class 1 products in terms of earthquake resistance and is capable of withstanding magnitude 9.0 earthquakes. The total length of the pipes exceeds 160 meters.

A month before, Atommash had completed the welding of ring joints on the upper semi-vessel for Xudabao Unit 3.

The welding process took 25 days, with the welding area kept continuously heated to 150–170 °C. After that, the temperature was raised to 300 °C and the semi-vessel was placed into the furnace for a heat treatment that imparted the required mechanical properties to the steel it is made of. The treatment process took three days, with the temperature reaching as high as 620 °C.

As soon as the heat treatment was finished, the semi-vessel was subjected to machining operations and underwent all the necessary quality control tests and procedures.

In total, Atommash will produce two reactor pressure vessels complete with internals and heads, and two sets of steam generators for Xudabao Units 3 and 4.

Construction of VVER-based nuclear power units is far from being the only area of cooperation between the Russian nuclear corporation and China. Rosatom also takes part in the development of CFR‑600, a 600 MW sodium-cooled fast neutron demonstration reactor scheduled to achieve its first criticality in 2024. CFR‑600 is the second Chinese-Russian project in fast neutron reactor technology. The first one was CEFR, a 20 MW fast neutron reactor built in 2010 at the Nuclear Power Institute of China with the participation of Rosatom. It was brought to capacity on December 22, 2014.

Russia and China also cooperate in science and research. Rosatom’s Research Institute of Atomic Reactors (RIAR) will conduct in-pile tests and post-irradiation analysis of graphite samples for China’s Fangda Carbon New Material Co. In 2018, during the visit of President Vladimir Putin to China, the two countries signed another contract for the supply of radioisotope thermoelectric generators (RITEGs) for the Chinese Lunar Exploration Program. The first contract was signed in 2012. RITEG is a power source that uses the energy of radioactive decay.

AtomStroyExport (ASE) is Rosatom’s engineering division and a global leader constructing most of the nuclear power plants abroad and having the world’s largest portfolio of nuclear construction contracts. The division is active in Europe, Middle East, North Africa, and Asia Pacific.

AtomEnergoMash (AEM) is Rosatom’s power engineering division and one of Russia’s largest power machinery producers providing comprehensive solutions in design, manufacture and supply of machinery and equipment for nuclear, thermal, petroleum, shipbuilding and steel-making industries.