Diversity of Nuclear Solutions

back to contentsIn early September, Ankara hosted Teknofest 2023, the 6th annual aerospace and technology festival. This year’s festival is dedicated to the centenary of the Turkish Republic and held through the course of the year in the country’s three largest cities, Istanbul, Ankara and İzmir. Over a million people and 125 organizations took part in the events held in Ankara. Rosatom and Akkuyu Nuclear were among the main sponsors of the festival.

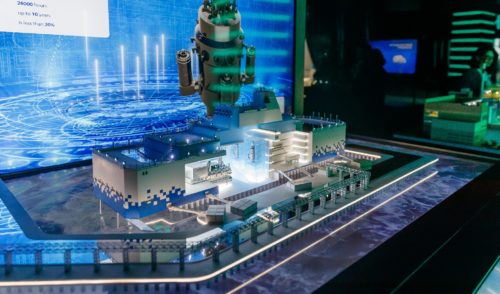

At this year’s festival, Akkuyu Nuclear presented an interactive exhibition booth. The visitors could become engineers of Turkey’s first nuclear power plant for a time and solve several exciting tasks in a nuclear quest. They first received helmets and vests, the mandatory gear of a nuclear plant engineer, and then designed an improvised nuclear power plant in a creative workshop. In the lecture area, young Turkish nuclear engineers told them about the Akkuyu NPP construction and the role of nuclear power in the country’s technological development. After that, the quest players had a chance to test their dexterity, attention and physical fitness, which are all important for a nuclear plant engineer, in the interactive game room. At the final stage, the guests took a knowledge test on nuclear energy and could contribute to Akkuyu Nuclear’s initiative aimed at protecting the rare turtle species Caretta Caretta in the Mersin Province. The quest players received mock certificates of Akkuyu engineers and keepsake souvenirs. All in all, over 3,000 guests visited the exhibition booth of the Akkuyu Nuclear Power Plant.

“Nuclear power is a field for very enthusiastic and dedicated professionals. Many of them decide to become nuclear engineers at an early age, especially if their parents work in the nuclear industry. We pay much attention to the younger generation as we organize regular tours to the Akkuyu site for the children of our employees and hold lectures in schools. All this is part of a major educational and career guidance project for children. This year we wanted children and teenagers from Ankara and other Turkish cities and provinces to try themselves as nuclear engineers at Teknofest, learn more about this wonderful and necessary profession, get interested and, perhaps, come to work at Turkey’s first nuclear power plant in the future,” said Anastasia Zoteeva, CEO of Akkuyu Nuclear.

News from the Akkuyu construction site

In late August, concreting of the foundation for the turbine island was completed at Unit 2. This key operation enables workers to proceed with installing components of the turbine, which is involved in converting mechanical energy into electricity.

“The foundation under the turbine is a complex structure capable of taking and evenly distributing the loads produced during the turbine operation,” Anastasia Zoteeva explained. After the foundation gains strength, a special commission consisting of the representatives from Turkey’s Nuclear Regulatory Authority (NDK) and an independent inspection organization will check the quality of concrete. “Like any other operation at the construction site of Turkey’s first nuclear power plant, the concreting of the turbine foundation at Unit 2 is fully compliant with the IAEA safety standards, laws and regulations of the Turkish Republic, and current requirements of the global nuclear community,” Akkuyu Nuclear CEO added.

An overhead crane with a lifting capacity of 350 tons was put into operation in the turbine building of Unit 1. This is the primary crane for lifting, transportation and handling tasks performed on the turbine island during the construction and operation of the plant. A total of three overhead cranes will be installed at different heights in the turbine building, all linked together via a high-tech control system.

“Once the installation is complete, all the cranes will be used to install equipment and move heavy cargoes in the turbine building. When the power unit is in operation, the cranes are needed for maintenance and repairs on the core and auxiliary equipment installed inside the turbine hall. The service lifespan of each crane is designed to last as long as the entire life of the power unit, that is, the cranes have the highest degree of reliability ensured through design and manufacture,” explained Sergey Butskikh, First Deputy CEO at Akkuyu Nuclear and director of the under-construction nuclear power plant.

In mid-August, a high-precision ion chromatograph, second to none in Turkey in terms of the lower measurement limit, was put into operation in the nuclear plant’s chemical laboratory. The device is designed to analyze water used in the primary circuits of the reactor units. The first circuit is a closed one, withinwhich ultra-pure demineralized water circulates between the reactor and the steam generator. The ion chromatograph analyzes its purity. After the device was installed, production of demineralized water began. It will be used during the reactor flushing and safety system tests.

See for yourself

The Akkuyu NPP is the largest but not the only Russian-Turkish nuclear project. In 2021, Rosatom signed a contract with Turkey’s Kuzey Star Shipyard to build a floating dock. It is designed to do repairs of nuclear icebreakers and nuclear support vessels.

Russia is the only country in the world to have a nuclear icebreaker fleet. Icebreakers are needed to escort cargo ships on the Northern Sea Route (NSR) running through the seas of the Arctic Ocean. Covered with ice most of the time, the NSR is the shortest water route between Europe and the Asia Pacific. Russia’s Atomflot (a part of Rosatom) operates seven nuclear-powered icebreakers, including three universal icebreakers of a new design. Several more are under construction. This summer, Turkish media had the opportunity to see these unparalleled vessels with their own eyes. As part of a press tour organized by Rosatom, they visited the most advanced icebreaker Arktika. The icebreakers of this design have a capacity of 60 MW and can travel through 3-meter thick ice. In an interview with the Anadolu news agency, Arktika’s Captain Alexander Skryabin said the icebreaker could operate in both deep ocean waters and in the shallow waters of Siberian rivers.