In Focus: SHELF-M Reactor

back to contentsAlong with small modular reactors, micro reactors are at the center of Rosatom’s attention. SHELF-M is the closest among them to become tangible. Here is our story of the reactor specifics and construction prospects.

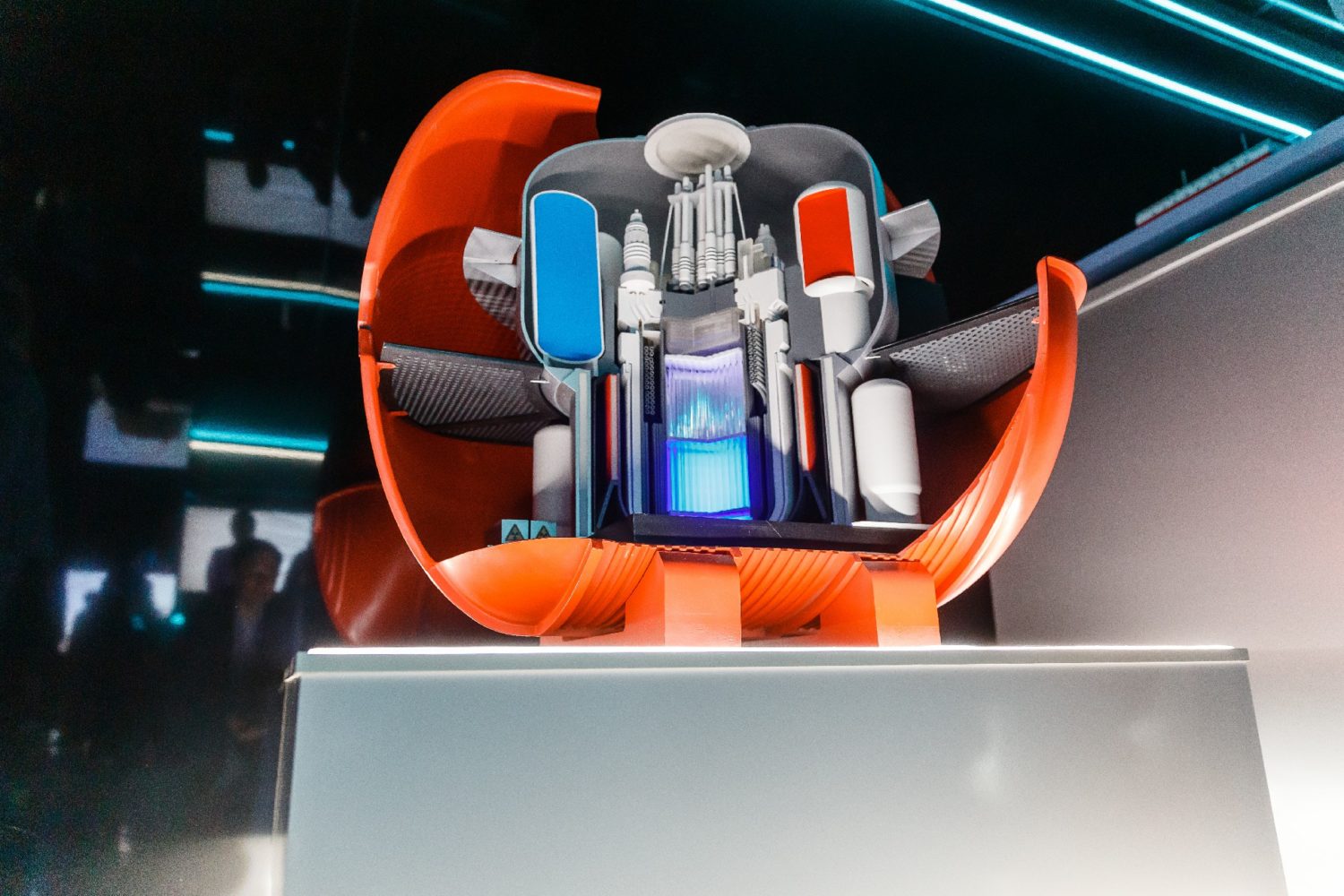

Structural highlights

With a thermal capacity of 35 MW and an electric capacity of 10 MW, SHELF-M is a water-cooled, water-moderated reactor that will be fueled with uranium dioxide dispersed in a silumin (aluminum-silicon alloy) matrix. The refueling interval will be eight years. The fully assembled reactor module will be 11 meters long and 8 meters in diameter. Weighing 370 tons, it will have a service life of 60 years. If necessary, the reactor can be transported from one site to another, for example, on a barge.

Working groups established by Rosatom and local authorities of Russia’s northern communities have identified potential installation sites for the pilot SHELF-M unit. “We are working on the concept and front-end engineering design for the nuclear power plant in relation to one of the possible sites,” says Denis Kulikov, chief designer of reactors for small nuclear power plants at the Dollezhal Research and Development Institute of Power Engineering (NIKIET, part of Rosatom).

SHELF-M is a channel-type reactor. The layout of its core and fuel composition is similar to that used in nuclear-powered icebreakers.

The fuel rods for the pilot reactor are made of components that have been tested and proven before. For example, the cladding material is a time-proven chromium-nickel alloy 42KhNM, while the geometry of the cross-shaped fuel rod is similar to those used in the SM‑3 and PIK research reactors. The chief designer and technologist of the basic fuel rod modification is the Bochvar Russian Research Institute of Inorganic Materials (VNIINM, part of Rosatom).

SHELF-M can operate in a natural primary coolant circulation mode at approximately 30 % of its rated power. NIKIET sees no need in making the reactor cooled entirely through natural circulation since the reactor is planned to be transported fully assembled and must have limited dimensions for this purpose. However, some of the SHELF-M safety systems operate on natural laws alone: for example, the emergency reactor cooling and cooldown systems do not require power supply or pumps to perform their functions.

Solutions for the future

NIKIET is working on the concept design of the reactor unit and plans to finish it by the end of this summer. Then, they will proceed with the development of materials for the primary systems and equipment of the power unit.

At the same time, research studies are carried out to provide experimental evidence for the technical solutions adopted for the reactor. For instance, engineers are analyzing whether the equipment components made with additive technology or composite materials can be used in the reactor. “We are looking, among other things, for a solution to replace the structural material of the quite massive external tight-proof protective shell with a composite material. This should decrease the weight of the module by several dozens of tons while maintaining the mechanical and strength properties of the capsule,” Denis Kulikov comments.

In addition research is conducted to develop a new type of fuel rods for the serial reactors. This is a bimetallic fuel rod developed at NPO Luch (part of Rosatom). The structure of the core, the type of fuel assemblies, and even the geometry of the fuel rods will remain the same while the fuel composition will be uranium metal filaments placed in a niobium alloy. The fuel rods, made to a similar design but using zirconium, are used in the core of the Kazakhstan research reactor IVG.1M.

Remote control

Robotic automation is another concept developed for the new reactor. Since personnel will have no access to the reactor containment during operation, many operations will have to be performed by robots.

“We plan to make mock-ups of critical robotic units and test them in a working environment. The most interesting task, in my opinion, is the development of a remote control system. We won’t be able to fully deploy it at the pilot nuclear plant — it will be operated from a conventional control panel. But after the system is tested in backup mode and its reliability and safety are confirmed at the pilot unit, we hope to make the remote control a standard feature,” Denis Kulikov says.

Market niche

There is a vast market for modular reactors with a capacity of up to 10 MW per module. They will replace obsolete generation capacity, both nuclear and fossil-powered, in the medium term and serve as local power sources for new industrial facilities in remote areas with decentralized power supply.

Plans for Shelf-M

2024 — Completion of the engineering design for the reactor and basic equipment of the nuclear power plant; start of on-site works

By 2026 — Completion of endurance tests on the main assemblies and structural elements

By 2027 — Start of equipment delivery to the deployment site

2030 — First criticality, first power, and commissioning

2032 — Start of production of the second and subsequent SHELF-M power units