Fast, Sodium, and Upgraded

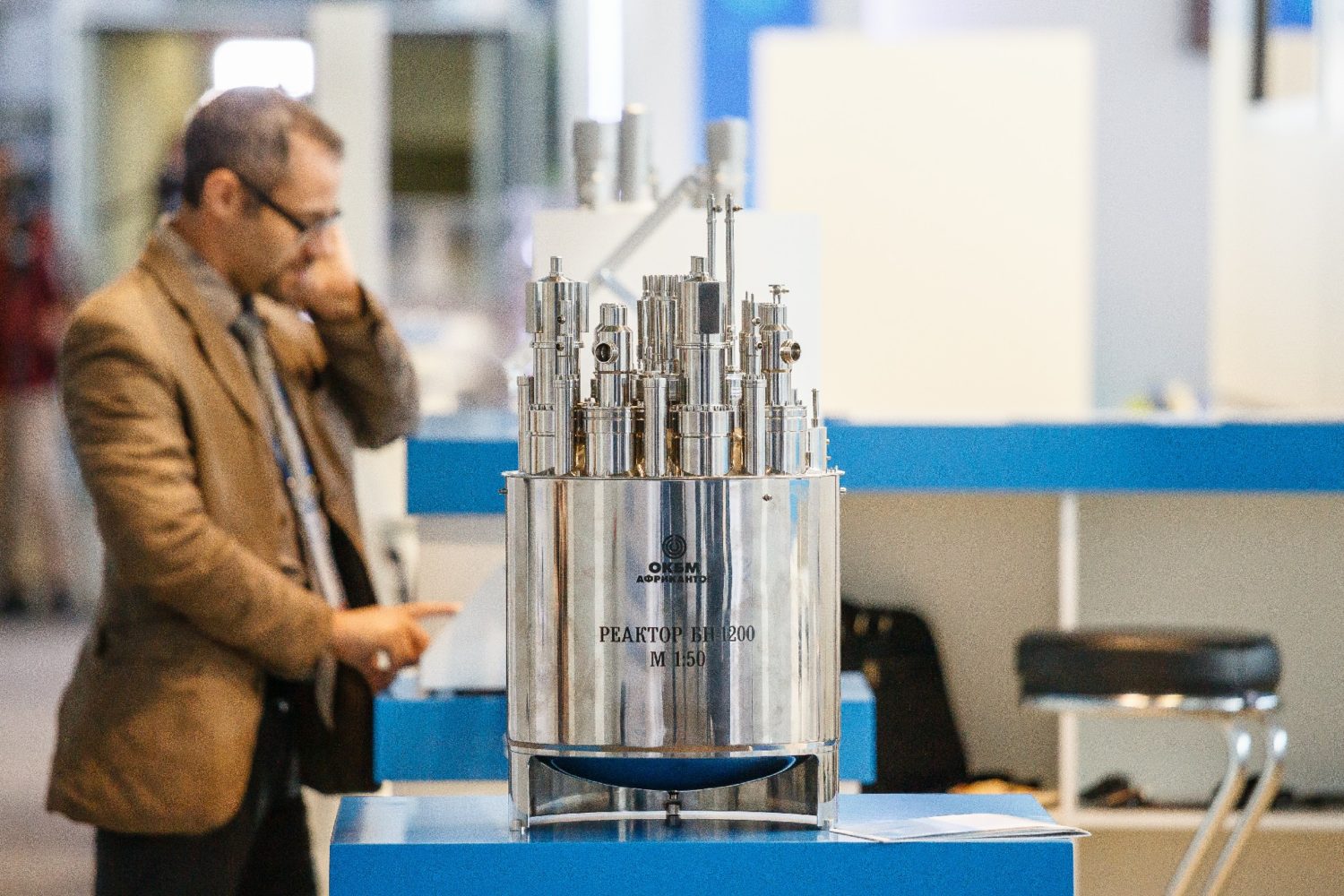

back to contentsLarge sodium-cooled reactors are yet another type of reactor technology that Rosatom is focusing on. Nuclear engineering company OKBM Afrikantov is currently developing BN‑1200M, a sodium-cooled reactor, to be installed at Beloyarsk Unit 5, which will contribute to closing the nuclear fuel cycle.

BN‑1200M is an upgraded reactor of the BN fast neutron series. Cooled with sodium, it will have an electrical capacity of 1,200 MW and a thermal capacity of 2,800 MW. It has a four-loop design with a symmetric layout of the loops. Oxide and nitride fuels are being considered for the use in BN‑1200M. According to Alexander Ugryumov, Senior Vice President for Research and Development at TVEL (a part of Rosatom), the dense MUPN (mixed uranium-plutonium nitride) fuel is currently the priority.

BN‑1200M taps into many years of Rosatom’s expertise in the development and operation of fast breeder reactors. The BN‑1200M design uses the time-proven solutions from BN‑600 and BN‑800 reactors. BN‑600 is also used to validate the use of structural materials and fuel under the design operating conditions.

BN‑1200M meets the latest, more stringent requirements to safety systems and controls for beyond-design-basis accidents, and incorporates the most advanced technical solutions. These include, for example, a hydraulically suspended absorber rod for passive shutdown system and a device designed to hold and cool molten fuel inside the reactor vessel in the event of a core meltdown accident.

The safety of the reactor is also enhanced by placing the systems and equipment containing radioactive sodium inside the reactor tank. The autonomous heat exchangers of the emergency heat removal system, which are also installed inside the tank, along with the natural coolant circulation through the circuits, contribute to reducing the likelihood of severe damage to the core. The capacity of the BN‑1200 in-vessel storage has been increased in order to unload fuel assemblies from the reactor directly into the spent fuel pool, eliminating the need for a sodium drum.

Compared to the BN‑600 and BN‑800, the power density of the BN‑1200 core is almost twice as low, which significantly extends the refueling interval. The use of larger fuel rods and fuel assemblies, mixed uranium-plutonium fuel, and new structural steels with increased radiation resistance ensures deeper burnup and reduced consumption of fuel assemblies. The use of expansion bellows to compensate for thermal expansion of the pipes has led to a reduction in their length. With the implementation of these new technical solutions, the length of sodium systems has been reduced considerably; radioactive sodium leaks and contact with air have been eliminated.

“The adopted technical solutions, such as passive safety systems and the use of self-protection properties inherent in the sodium coolant, make the reactor as safe as there will be no need to evacuate people in the event of any technically possible accidents,” says Sergey Shepelev, Chief Designer of BN reactors at OKBM Afrikantov.

The design of the reactor also incorporates solutions that will make BN‑1200M more cost-efficient. The weight and production costs of its systems and components have been reduced through the modifications in the secondary circuit main circulation pump and the fuel loading system, replacement of sectional modules with large-size modules in the steam generators, and improvements in the emergency heat removal system and the primary-circuit cold trap. In-depth improvements in the reactor unit layout, streamlined construction solutions, and an optimized master plan will reduce the volume of construction work.

As a result, the estimated costs of capital construction, and, accordingly, electricity generation, will decrease, thus making the reactor competitive with other power generation units currently under development or in use.

“The BN‑1200M project follows Russia’s nuclear power development strategy, which involves creating a two-component nuclear power system based on the new generation of fast and thermal reactors. It will ensure a continuous supply of fuel, improve spent fuel and radioactive waste management, and facilitate a zero-carbon transition,” Sergey Shepelev commented.

Due to its physical properties, the fast neutron reactor can be operated on different plutonium isotopes extracted from the spent fuel of both fast and thermal neutron reactors. It can also ‘burn’ minor actinides to produce fresh plutonium for fuel and fabricate desirable isotopes.

The service life of the BN‑1200M reactor unit is at least 60 years. As Sergey Shepelev notes, there is potential to extend its lifespan to 80 years, increase the utilization factor from 0.9 to 0.91, extend the service life of steam generators from 30 to 60 years, and lengthen the refueling interval.

It is expected that the project’s financials will be approved in 2023, followed by public hearings. The next step will involve obtaining approval from the national expert panel Glavgosexpertiza and securing a site license from the federal regulator Rostechnadzor. This will be followed by the development of engineering design documents, which will be also reviewed by Glavgosexpertiza. The task for 2026 is to obtain a construction license. The first concrete pouring is scheduled for 2027, with capital construction works and delivery of long-lead equipment to be completed by 2030. The plan for 2031 is to obtain an operating license, bring the reactor to criticality and then to power.

“We have accumulated extensive experience in the sodium fast technology. The existing facilities — the BOR‑60 research reactor and the commercial BN‑600 and BN‑800 power reactors –operate efficiently. I believe we are ready to commercialize the sodium fast technology and maintain Russia’s leading position in this field,” Sergey Shepelev concluded.

TVEL is Rosatom’s fuel division and one of the world’s largest suppliers of nuclear fuel. TVEL is a monopoly supplier of nuclear fuel to all power, marine and research reactors in Russia. The company fuels nuclear power plants in 15 countries, or every sixth power reactor in the world.