High-Temperature Gas-Cooled Reactor

back to contentsRosatom is developing a project for an engineering nuclear power station with a high-temperature gas-cooled reactor (HTGR) and a hydrogen plant. The project is a new round in the development of both gas-cooled reactors and hydrogen technology.

Background

The engineering nuclear power station (ENPS) under development has several predecessors. The first one was a Soviet-designed experimental reactor ABTU‑15 and a pilot plant ABTU-ts‑50 with a VGR‑50 reactor. It was designed for power generation and radiation-induced modification of materials (polyethylene, wood, and others). In the 1970s, a pilot high-temperature gas-cooled reactor VG‑400 was developed to generate electricity and high heat energy. This was followed by the development of modular HTGRs, such as the VGM‑200 pebble-bed reactor and MVGR-GT power unit with a closed-cycle gas turbine. That was the time when Soviet engineers developed the conceptual design of a VTGR‑10 small power reactor and principles of combining nuclear and hydrogen technologies, which implied the use of hydrogen produced with nuclear power as a source of energy for industry, transport and households.

In the 1980s, the Soviet government adopted a national hydrogen economy program that provided for the development of HTGRs for energy-intensive applications and processes. For example, the VG‑400 reactor design was modified for the production of ammonia fertilizers. It was planned to build five plants with HTGRs but the plans were disrupted by the fall of the Soviet Union.

However, the idea to build a high-temperature gas-cooled reactor persisted to evolve into the development of a 600 MW reactor with a direct gas turbine cycle, which was underway through 1998–2012. General Atomics (US), Framatome (France) and Fuji Electric (Japan) participated in the development. The project revived cooperation between Russian companies and complemented their competencies.

Current status

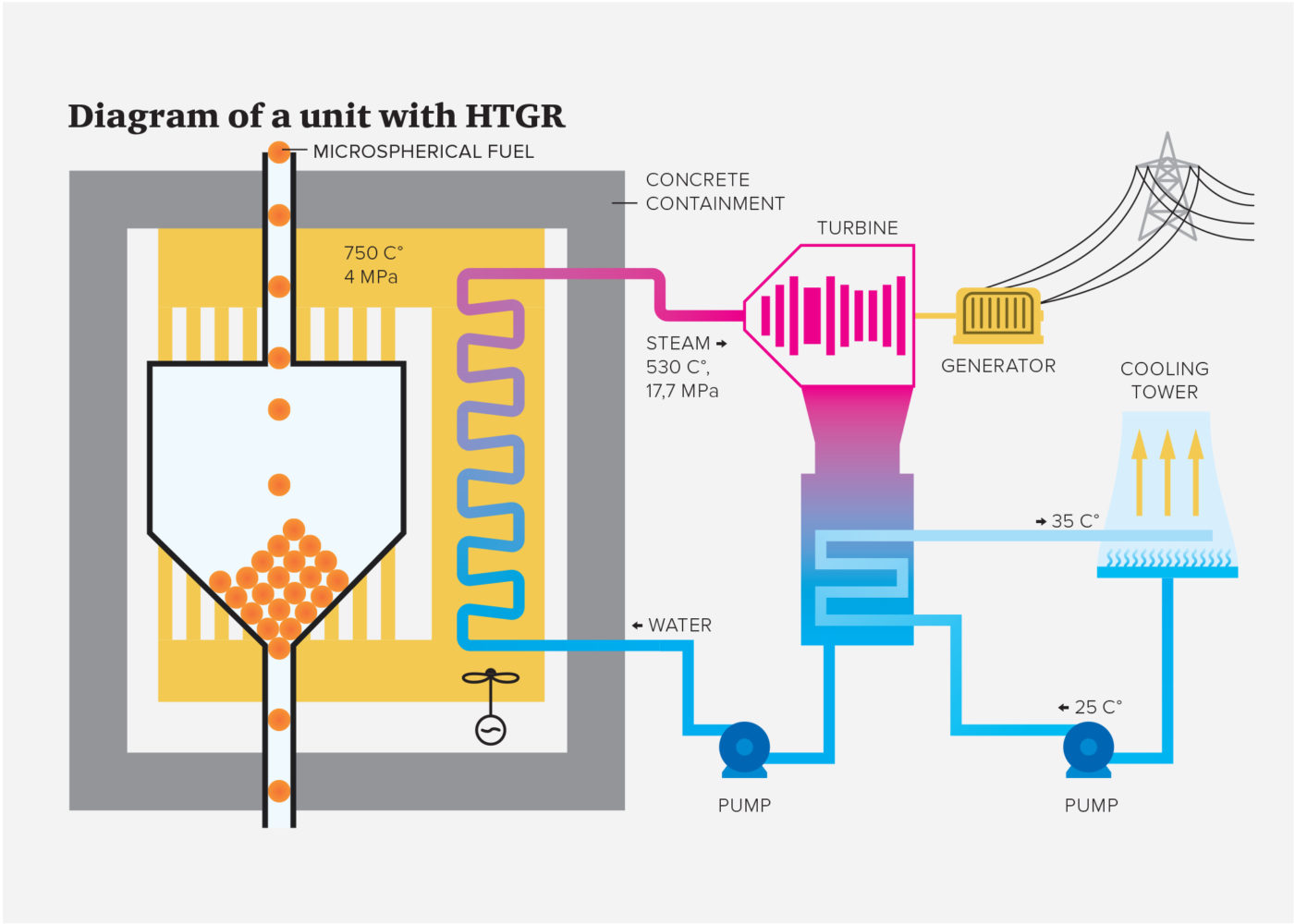

Today, development of an advanced ENPS with a high-temperature helium-cooled reactor and a hydrogen plant is in the front end engineering design phase, with a site for the ENPS being selected. The principal difference of the current ENPS design from the previous ones is that the hydrogen production plant is made an integral part of the nuclear station. Hence, the final product of the station will be not heat but hydrogen, which can be stored, transported and sold to customers.

Engineers had to make several tough choices. For example, they decided not to use any foreign technology in the ENPS and opt for Russian technology only. For this reason, a carbon-free steam methane reforming (SMR) process was chosen instead of electrolysis as a preferred hydrogen production method. The SMR process has long been mastered in Russia, and the country also has plenty of both methane and water for it. Another choice to be made was whether to use an intermediate circuit for transferring heat to the hydrogen plant. It was decided for safety reasons to physically separate the hydrogen-producing and reactor circuits with an intermediate helium circuit. One of the next questions to be answered is therefore how far apart the reactor and hydrogen-producing circuits will be placed so that no accident at the hydrogen plant can damage the reactor.

ENPS parameters

It is assumed that the high-temperature gas-cooled reactor will have a thermal capacity of 200 MW. The hydrogen plant will be capable of producing 110,000 tonnes of hydrogen per year. Since the ENPS will have four HTGRs and, accordingly, four hydrogen plants, the station’s total capacity will be 800 MW of thermal energy and 440,000 tonnes of hydrogen per year.

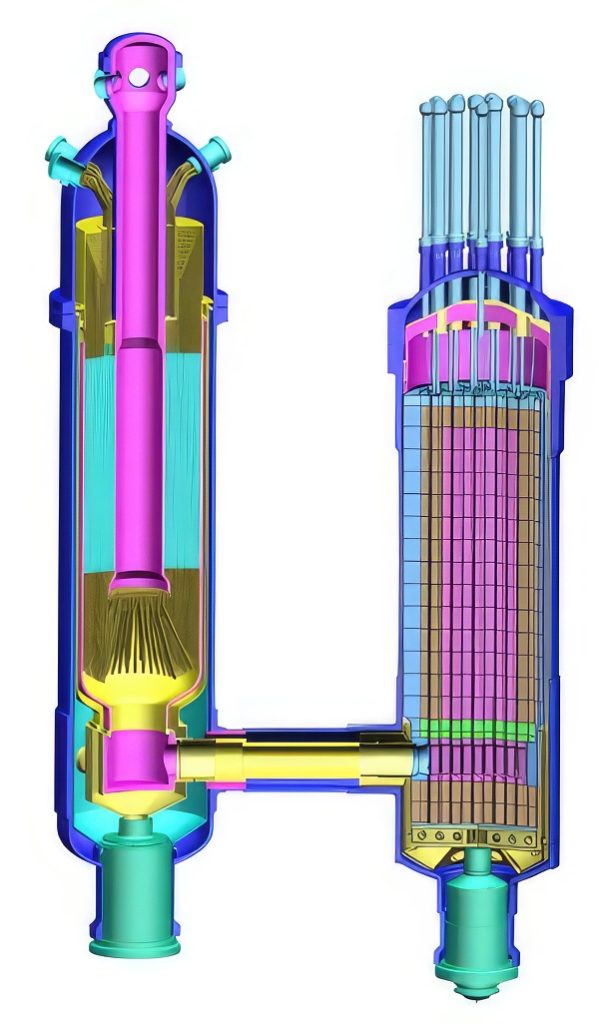

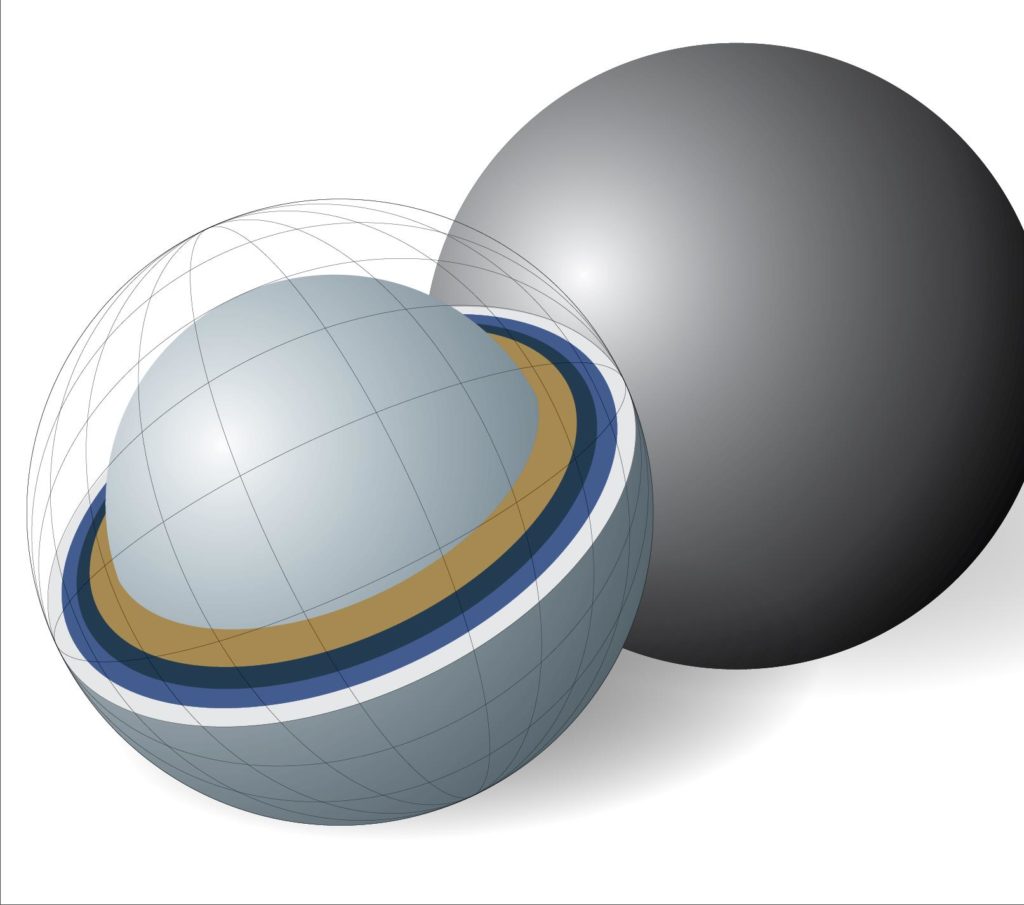

The temperature of helium will be 330 °С at the reactor inlet and 850 °С at the outlet. Fuel elements are being designed to meet inherent safety requirements: the reactor must be capable of shutting down without triggering shutdown systems, and residual heat removal from the shut-down reactor needs no external energy source or staff involvement. Another requirement is to make the reactor more powerful given the existing reactor vessel fabrication capabilities. As a result, the developers chose to use block-type fuel assemblies as fuel.

Prospects

The ENPS project is expected to be brought to the investment stage in 2024 as the technical design of the reactor unit, declaration of intent and other documents will be prepared by that time. The design and licensing stages of the ENPS project are scheduled to be completed in 2028, followed by construction of the first unit, which is expected to be completed in 2032. The remaining units are planned to be built in 2035.

Context

The engineering nuclear power station is one of the investment projects carried out by RosEnergoAtom (part of Rosatom) under the umbrella of developing nuclear and hydrogen technologies for massive hydrogen production and consumption applications. Apart from the ENPS, RosEnergoAtom develops electrolytic methods of hydrogen production with electricity from nuclear power plants. A pilot modular electrolysis plant with a 50 Nm3/h anion exchange membrane is ready for trials. In 2025, the Kola Nuclear Power Plant plans to commission a 200 Nm3/h testing facility for hydrogen production by electrolysis.