Lead-Bismuth: Natural Circulation

back to contentsThis article starts a new series titled Reactor Technologies. Throughout this year, we will tell you about new peculiar types of nuclear reactors developed by Rosatom researchers and engineers. We will begin with lead-bismuth fast neutron reactors. Known for quite a long time, the lead-bismuth technology was initially used in submarine reactors but now is applied by Russian engineers to develop different-capacity reactor designs.

Coolant specifics

Lead-bismuth eutectic has advantageous thermal properties. This alloy has a relatively low melting temperature of 123 °C (to compare, lead melts at 327 °C), so there is no need in creating heat-resistant structural materials. By contrast, its boiling temperature is high (1,670 °C), enabling it to obtain superheated steam at a relatively low pressure (high pressure in the primary coolant loop has to be taken into account in the design of pressurized water reactors, including VVER). The higher the steam temperature, the higher is the efficiency of a power plant. And, unlike sodium, lead-bismuth eutectic does not react with air or water, excluding the possibility of hydrogen-emitting explosions or fires.

Little bit of history

Initially, fast neutron reactors were intended to fabricate plutonium as nuclear fuel was meant to be renewable even at the dawn of the Soviet nuclear industry. The reason was mundane — there were no large uranium deposits discovered in the USSR at that time, and the country strove for a strategic goal of sufficient power generation. Lead-bismuth eutectic ‘lost the competition’ to sodium as a coolant for fast neutron reactors because plutonium was produced faster with sodium. However, lead-bismuth was not forgotten. Alexander Leipunsky, one of the fathers of the Soviet nuclear project and a chief researcher of the fast reactor development program, proposed to use the alloy in nuclear reactors for submarines.

The idea was innovative, but the properties of lead-bismuth eutectic had not been studied thoroughly. Dozens of test facilities were built but research, design and construction of the nuclear submarine ran almost simultaneously due to urgency of the task. The lack of knowledge played its part: engineers had to study the reactor properties in the process of operation, fixing problems and adjusting production and operation manuals ‘on the go.’ As a result of those efforts, six nuclear submarines with lead-bismuth reactors had remained on duty with the Navy until 1996. Their total service life amounted to almost 80 reactor-years in different modes of operation, with advantages of the technology confirmed and initial design solutions validated.

Going onshore: SVBR‑100

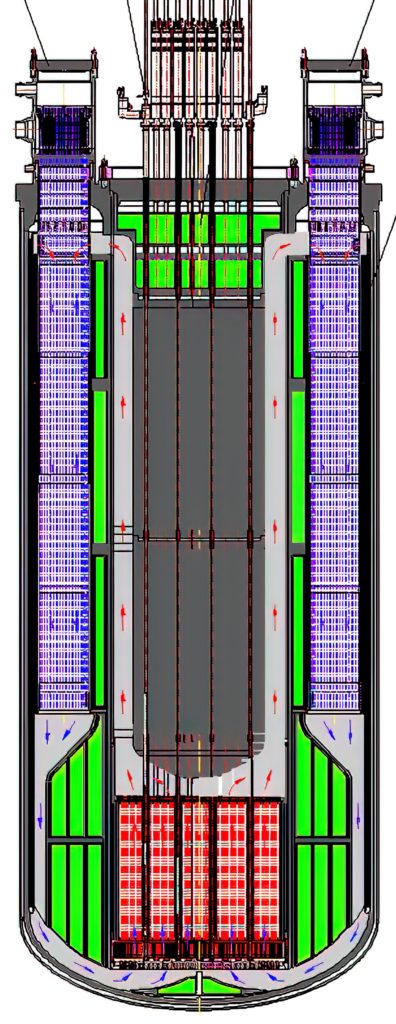

In the second half of the 1990s, a blueprint design was developed for a nuclear power plant consisting of two 1,600 MW units with 16 lead-bismuth fast neutron 100 MW reactors each. The work was later suspended and resumed in 2006 as engineers proceeded with the design of a pilot reactor. Soon Rosatom and Irkutsk-based utility IrkutskEnergo established a company, AKME Engineering, to carry out the project (currently under development).

The expected power capacity of the lead-bismuth fast reactor (abbreviated as SVBR in Russian) is 100 to 130 MW. The reactor can run on either uranium or uranium-plutonium, both oxide and nitride, fuel. SVBR‑100 can also be loaded with fuel assemblies containing up to several percentage points of minor actinides. The reactor is planned to be mounted in a sealed box, and all of its systems placed in a containment building with 1.5‑meter walls.

Rosatom also develops two more lead-bismuth cooled reactors, SVET-M and SVGT‑1, on its own.

SVET-M reactor

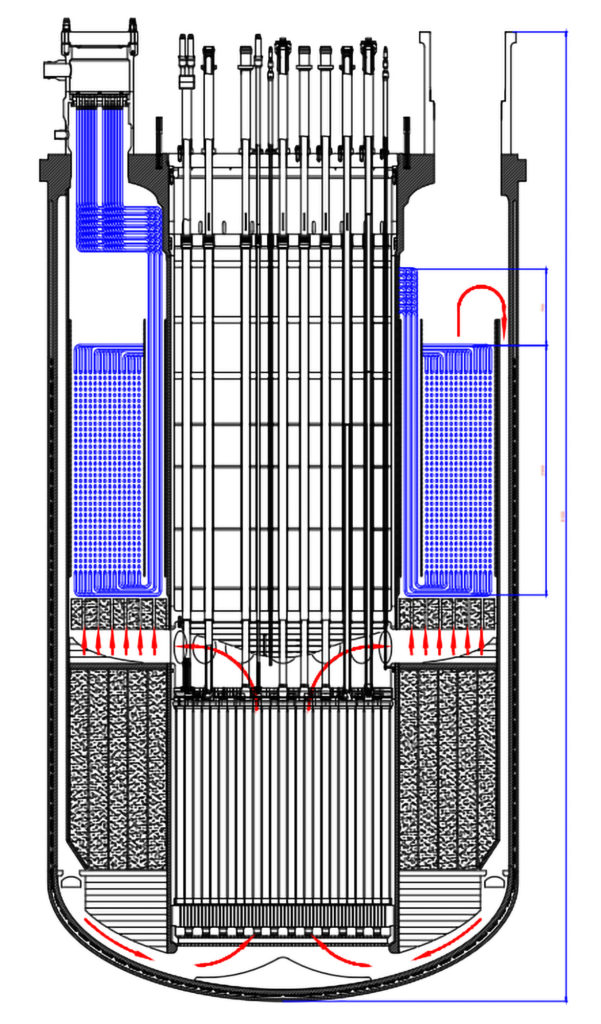

In Russian, SVET-M stands for a ‘natural circulation lead-bismuth modular reactor.’ This is an integral fast neutron reactor: its primary coolant systems are placed inside a single containment with no primary circuit pipes and fittings — they are simply not needed. Natural circulation of coolant is its primary distinction. That means that the reactor has no circulation pumps and coolant is driven by the difference in pressure in a hot reactor core and a relatively ‘cold’ steam generator. Since the temperature of lead-bismuth differs greatly in the hot and ‘cold’ sections of the circuit, this creates a higher pressure (as compared to other coolants) and allows for reducing the reactor height and saving on structural materials.

SVET-M is being developed in a number of designs ranging from 1 to 50 MW of electric power, the most elaborated of them being a 10 MW design. The temperature of steam exiting the reheater reaches 445℃. High temperature increases efficiency of the reactor unit. Similar to SVBR‑100, SVET-M can run on either uranium or uranium-plutonium, both oxide and nitride, fuel. SVET-M is developed at OKB Gidropress (part of Rosatom’s engineering division AtomEnergoMash). Schematic design of the reactor was completed in 2022.

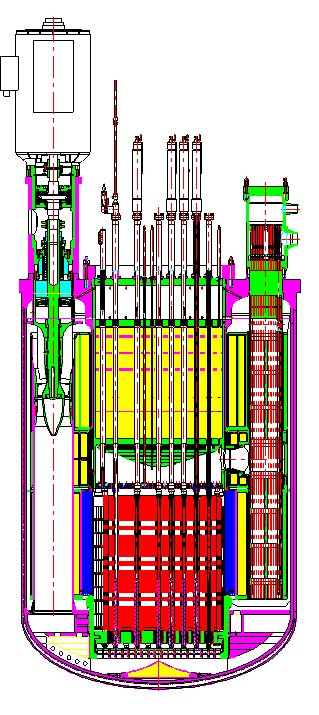

SVGT‑1 reactor

SVGT‑1 stands for a ‘gas turbine lead-bismuth 1MWe reactor.’ Developed at the Leipunsky Institute of Physics and Power Engineering (part of Rosatom’s research division), it belongs to microreactors on the IAEA scale. It is a combination of a lead-bismuth reactor and a gas turbine plant, Anton Verbitsky, Head of the Fast Reactor Safety Assessment and Software Laboratory at Leipunsky Institute, explained in an interview for the Atominfo.ru web portal. Featuring a natural circulation design, SVGT‑1 does not have pumps either. Currently, the reactor is at the preliminary stage of development. A plan has been prepared to proceed with engineering studies needed to develop a detailed design. If the plan is approved, engineers will begin working on the detailed design in three years. According to preliminary estimates, the entire design cycle will last seven to ten years.

All developers believe that lead-bismuth reactors have good prospects on the back of growing interest in small nuclear power plants and inherent safety of coolant circulation.