Going Onshore

back to contentsRITM‑200N will be Russia’s first small modular reactor (SMR) to be built onshore. Designed at OKBM Afrikantov, it differs from its predecessor, the RITM‑200 marine reactor. This article takes a deeper look into the differences.

Background

Russia’s first onshore SMR will soon be built in the Republic of Sakha (Yakutia). A cooperation agreement to this effect was signed between Rosatom and Yakutia’s Government in 2018. As set out in the document, OKBM Afrikantov and the State Specialized Design Institute (GSPI), both part of Rosatom, conducted a series of feasibility studies for a nuclear power plant with support from local authorities and organizations.

In February 2020, a pilot project was launched to build a small nuclear power plant with a RITM‑200N reactor in Ust-Yansk, Yakutia. The project provides for the pilot plant to have a single reactor with an electric power capacity of 55 MW.

In 2022, OKBM Afrikantov produced a detailed engineering design for the RITM‑200N reactor and its core. In April 2023, RosEnergoAtom obtained a site license from the Russian regulator Rostechnadzor.

At present, OKBM Afrikantov and GSPI are performing probabilistic safety analyses to prepare a safety report, which will be submitted to Rostechnadzor to obtain a construction license. OKBM Afrikantov has also set about developing detailed design documents for the reactor equipment, as well as commissioning and operating documents.

The work is concurrently underway to improve the existing regulatory framework, develop standardization documents for small modular reactors, and prepare the construction site.

Onshore modification

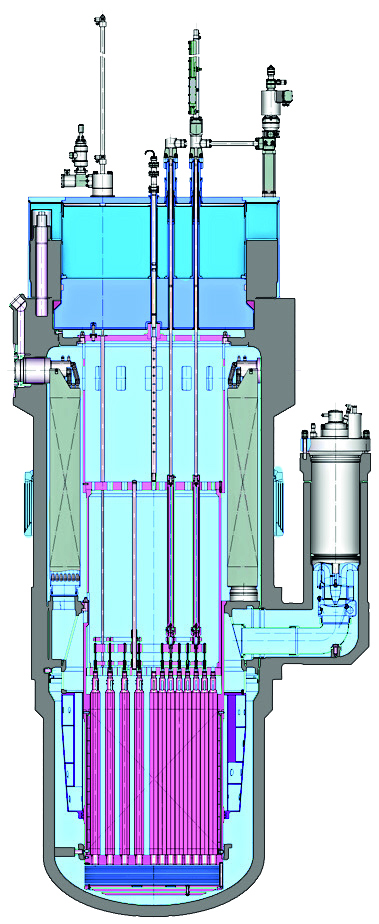

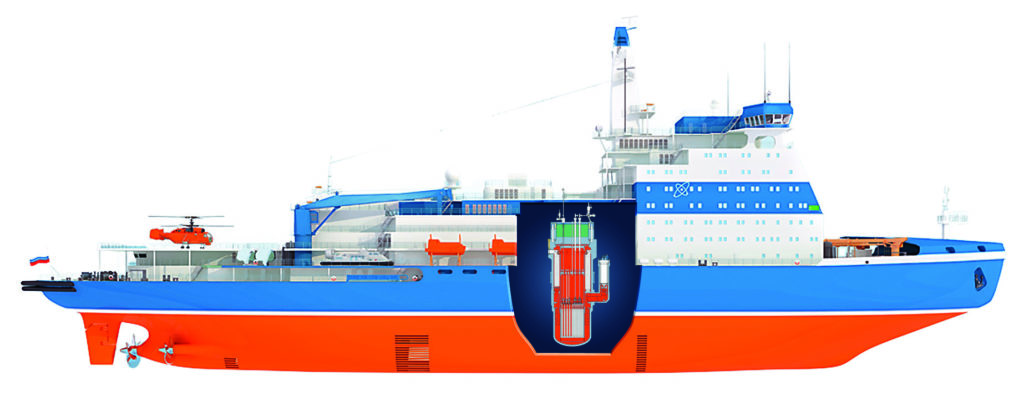

The prototype of the onshore SMR is RITM‑200, a universal marine reactor that is installed on nuclear-powered icebreakers. With all the necessary design-basis and experimental validations in place, the reactor has been produced on a commercial scale, featuring the SMR-critical properties, such as compact size, excellent load-following capabilities, and minimal liquid radioactive waste. Another essential feature is the integral layout of the reactor unit.

As far as possible, RITM‑200N replicates the design and layout solutions used in RITM‑200 and RITM‑200S, which are to be installed on upgraded floating power units.

In RITM‑200N, all the safety systems are designed to be redundant. That implies that the critical safety functions performed by active systems are all duplicated by passive safety systems.

Since the SMR will be built onshore and operated in the Arctic environment, special technical solutions have been incorporated in the RITM‑200N design, with necessary research and experimental studies conducted. Certain solutions aim to extend the service life of non-replaceable reactor equipment from 40 to 60 years. Improvements are also being made to passive safety systems to ensure the reactor remains safe for at least 72 hours even if it is completely de-energized or loses coolant (as happened at Fukushima). Another set of solutions provides protection against external impacts, encompassing both natural like earthquakes and man-made incidents such as a 20‑ton airplane crash.

Signaling devices will be installed in the reactor to monitor loss-of-coolant accidents in the primary circuit. The data they will provide will make emergency responses more timely and accurate. To monitor the reactor vessel condition during operation, the so-called ‘witness samples’ will be used. These are sacrificial test pieces made of the same steel as the reactor vessel is — they can be safely removed and, unlike the reactor, subjected to destructive testing.

The onshore RITM‑200 has a higher steam capacity (305 t/h compared to 248 t/h) and a higher power capacity (190 MW compared to 175 MW) than its marine version.

Fuel

The core of RITM‑200N reactors will contain 199 fuel assemblies with 1650 mm-fuel rods, 45 cm longer than those used in the marine reactors are. Instead of an intermetallic fuel, the onshore reactor will use uranium oxide ceramic as fuel, with uranium enriched to less than 20 %. These features almost double the energy potential of the fuel (8 TWh for an onshore reactor compared to 4.5 TWh for a marine reactor). Being used in the KLT‑40S reactor of the Akademik Lomonosov floating nuclear power plant, the ceramic fuel has proved functional. Fuel claddings will be made of corrosion-resistant alloy and, together with fuel rods, intended for operation in a load-following mode. The design life of the fuel for onshore reactors is the same 10 years as for the marine fuel.

Plans

The first concrete for the SMR foundation is planned to be poured in 2024. An operating license is expected to be obtained by 2027, followed by the commissioning of the plant in 2028. It is assumed that the key consumers of electricity from the Yakutian SMR will be mining and processing facilities at the large Kyuchus gold mine, rare-earth metal and tin deposits, and the nearby towns of Ust-Kuyga, Deputatsky, Kazachye and Severny.