Training Replica

back to contentsIn mid-July, a full-scale simulator was delivered to the Akkuyu NPP construction site. An exact replica of the control room of Turkey’s first nuclear power plant, it is designed for operating personnel training, licensing and upskilling. The development of training simulators for the nuclear power plants is a critical competency possessed by some of the Rosatom companies.

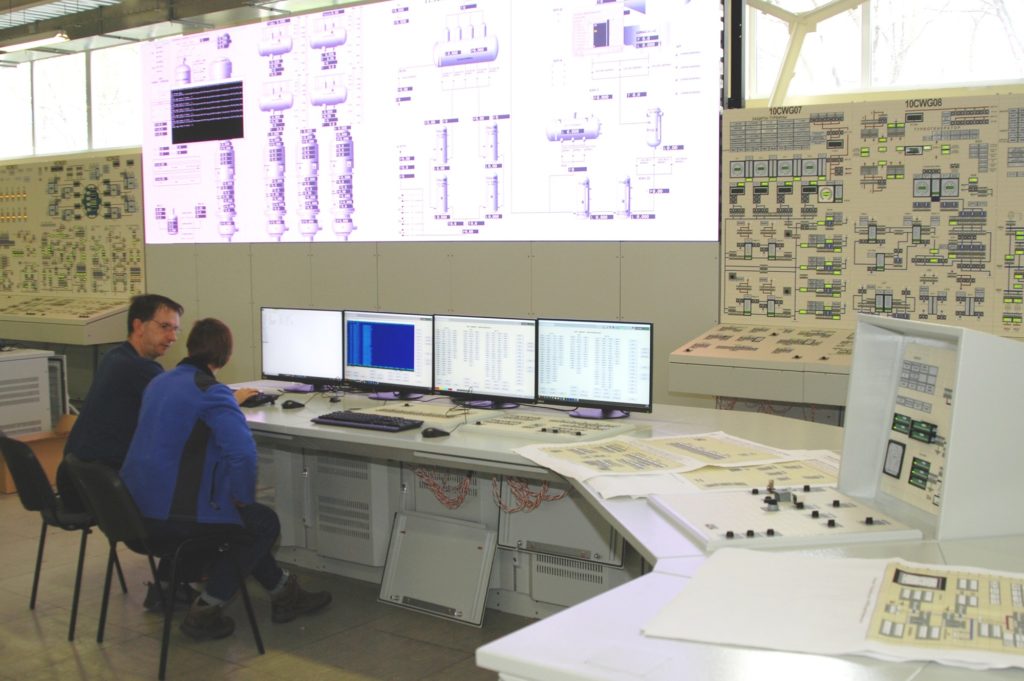

The full-scale simulator for Akkuyu is a digital twin of the plant’s instrumentation and control systems. Its hardware and software components are made to simulate the control room design — all the instruments, keys and control panels are identical to those of the control room in terms of arrangement, size, shape and color. This is essential for the staff to develop and reinforce the correct reactions. The information on the simulator displays and indicator lamps is also similar to that in the real control room. “With simulation training, personnel practice their behavior in different situations and under the conditions closest to reality before the nuclear power plant is commissioned,” Akkuyu Nuclear CEO Anastasia Zoteeva commented on the delivery.

Manufactured at the Russian Research Institute for Nuclear Power Plant Operation (VNIIAES, a part of Rosatom), the simulator uses a complex mathematical model that imitates every operating mode of the nuclear plant in real time.

Earlier, in June, an analytical simulator was delivered to the Akkuyu NPP. “The analytical simulator is based on the same real-time model of a power unit as the full-scale simulator. This model was created at VNIIAES and does not use any foreign modeling codes. It is a fully Russian-designed system that meets all Russian and international requirements,” says Viktor Chernakov, Head of the NPP Operation Modeling Support Department at VNIIAES. Its main difference from the full-scale simulator is that the control panels are not physical but are displayed graphically on touch-screen monitors.

The would-be operators of the Akkuyu NPP have been using the full-scale and analytical simulators since last year to improve their professional skills. They were first trained at VNIIAES and the Leningrad NPP. Seven groups of engineers completed a course for control room operators taught at VNIIAES. Among them were Russian and Turkish graduates of Russian universities with degrees in Nuclear Power Engineering. After the training was completed, the simulators originally installed at VNIIAES were disassembled and sent to Akkuyu. They will be re-assembled there and put into operation when the building of the training center is ready. After the reassembly, they will undergo a series of pre-commissioning tests to receive an operation permit.

VNIIAES produces full-scale and analytical simulators for nuclear power plants with RBMK, VVER‑440, VVER‑1000 and VVER‑1200 reactors, that is, any Russian-designed nuclear plants except for small stations (Bilibino and Akademik Lomonosov).

VNIIAES also develops digital twins of nuclear power plants. Released in March 2022, the Virtual NPP software package simulates the operation of more than 300 nuclear power plant systems by calculating over 3.5 million variables. Since February 2021, VNIIAES has been working on the development of a digital twin for small nuclear power plants with RITM‑200 and Shelf modular reactors. Tests on the new system and its release are scheduled for 2024.

VNIIAES is not the only Rosatom company engaged in the production of simulators for nuclear power plants. Another is the JET Engineering and Technical Center (JET ETC), which joined the Rosatom in 2020. JET ETC has supplied almost every simulator installed at the Russian-designed nuclear plants constructed abroad (two simulators in China, and one in each of India, Belarus and Bangladesh). Another simulator, intended for China’s Tianwan Units 7 and 8, was shipped this May. Although the shipment was scheduled for 2024, it was delivered well in advance to allow more time for personnel training. A simulator for Xudabao Units 3 and 4 is being prepared for shipment in early 2024, again ahead of schedule.

JET ETC is also working to upgrade a full-scale simulator at Paks I in Hungary, as well as producing simulators for Egypt’s El Dabaa and Russia’s Kursk II.

Another aspect of the company’s activities involves creating simulators and digital twins for other types of power plants. This April, for instance, the company signed an agreement with Belenergo and BelenergoRemNaladka at the TIBO 2023 forum in Minsk (Belarus) to deploy full-scale simulators and digital twins at power generation facilities operated by the Ministry of Energy of Belarus. The partnership also provides for the training and upskilling of power plant workers, as well as the introduction of best practices in power equipment operation.